Block copolymer containing phosphoric acid group, pigment dispersant and pigment colorant composition

A technology of block copolymer and polymer, which is applied in the field of pigment dispersant and pigment colorant composition, which can solve the problems of unclear pixel edge outline, insolubility, and reduced developability, etc., and achieve coating characteristics and long-term storage stability Excellent stability, excellent long-term storage stability, low viscosity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

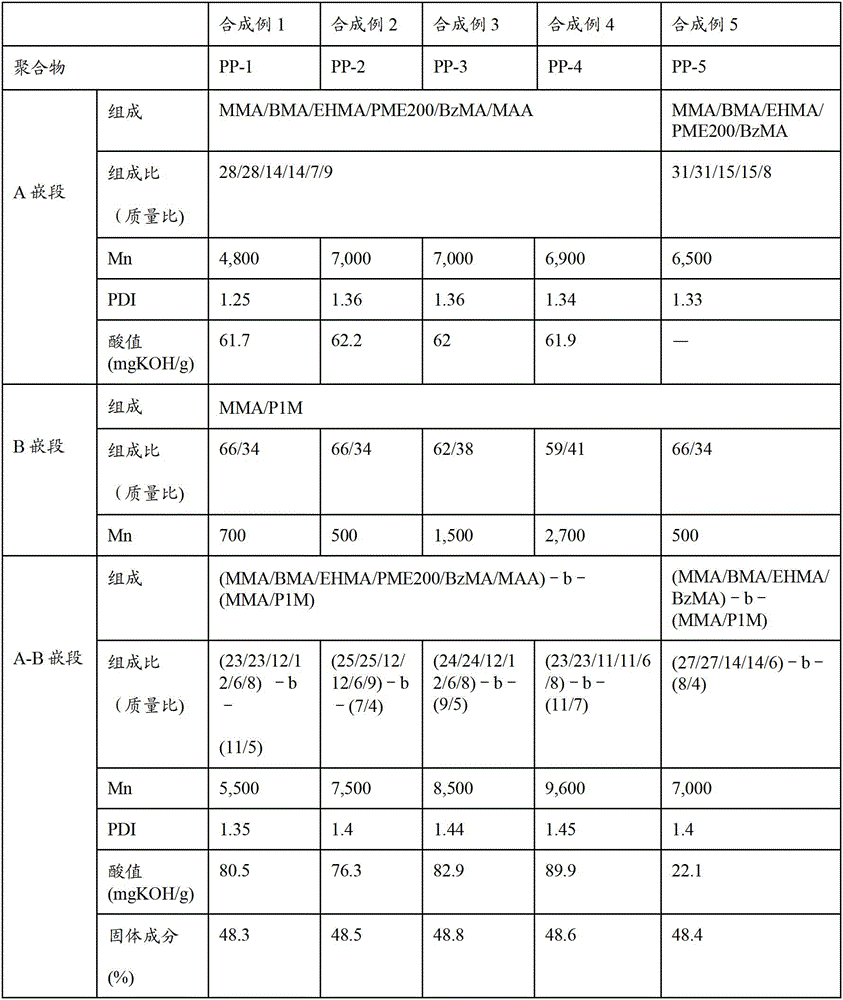

[0122] Hereinafter, examples are given and the present invention will be described in more detail. Hereinafter, "parts" and "%" in the text are mass standards unless otherwise specified.

Synthetic example 1

[0123] (Synthesis Example 1: PP-1)

[0124] 230 parts of propylene glycol monomethyl ether acetate (hereinafter referred to as "PGMAc"), 4.1 parts of iodine, 2,2'- 19.7 parts of azobis(4-methoxy-2,4-dimethylvaleronitrile) (hereinafter referred to as "V-70"), 57.6 parts of methyl methacrylate (hereinafter referred to as "MMA") , 57.6 parts of butyl methacrylate (hereinafter referred to as "BMA"), 28.8 parts of 2-ethylhexyl methacrylate (hereinafter referred to as "EHMA"), methoxypolyethylene glycol methacrylate ( n=3~5) ester (hereinafter referred to as "PME200") 28.8 parts, benzyl methacrylate (hereinafter referred to as "BzMA") 14.4 parts, methacrylic acid (hereinafter referred to as "MAA") 20 parts and 0.9 parts of 3,5-di-t-butyl-4-hydroxytoluene (hereinafter referred to as "BHT"). Polymerization was carried out at 40° C. for 7 hours while flowing nitrogen gas to obtain a solution of the A polymer block. The polymerization ratio of the A polymer block calculated from the ...

Synthetic example 2

[0127](Synthesis Example 2: PP-2)

[0128] Using 280 parts of PGMAc, 3.6 parts of iodine, 17.7 parts of V-70, 77.7 parts of MMA, 77.7 parts of BMA, 38.8 parts of EHMA, 38.8 parts of PME200, 19.4 parts of BzMA, 27.0 parts of MAA and 0.9 parts of BHT, in addition, with The above Synthesis Example 1 was operated in the same manner to obtain a solution of the A polymer block. The polymerization rate of the A polymer block calculated from the solid content was 90.1%. In addition, the Mn of the A polymer block was 7,000, the PDI was 1.36, the peak molecular weight was 9,500, and the acid value was 62.2 mgKOH / g.

[0129] Then, except using a mixture of 23.1 parts of MMA, 12.0 parts of P1M, 0.8 parts of V-70, and 35 parts of PGMAc, the same procedure as in the above-mentioned Synthesis Example 1 was performed to form a B polymer block and obtain an A-B block containing Polymer solutions of copolymers. The solid content of the obtained polymer solution was 48.5%, and the polymerizat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com