System for decomposing ammonia to prepare hydrogen on the basis of after heat of heat engine gas exhaust

A technology of exhaust waste heat and hydrogen production system, which is applied in the field of ammonia decomposition hydrogen production system, can solve the problems of high material cost, large compression work consumption, complicated operation, etc., and achieve the requirements of meeting hydrogen consumption, reducing heating effect, and high calorific value Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention is described in further detail below in conjunction with accompanying drawing:

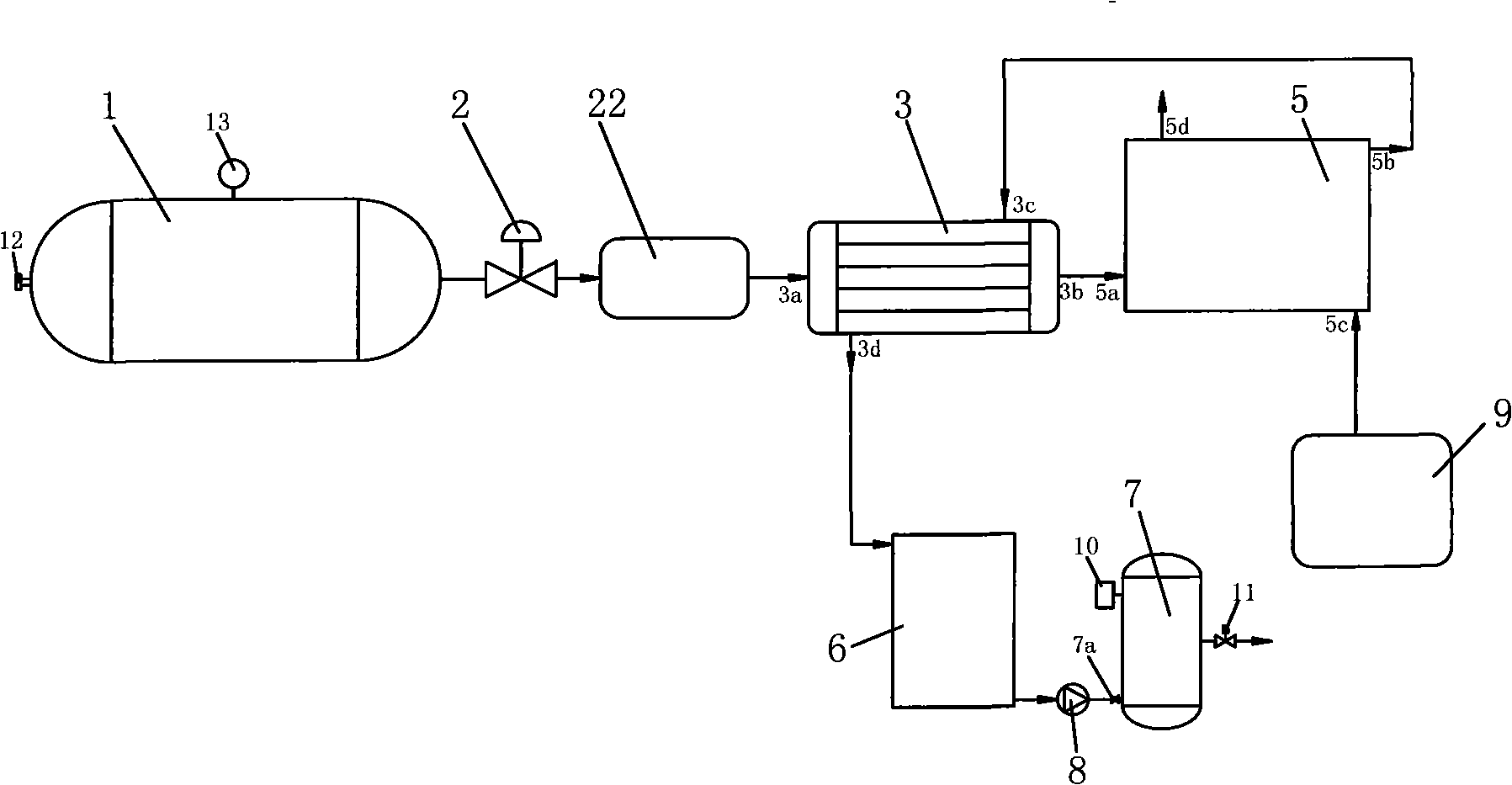

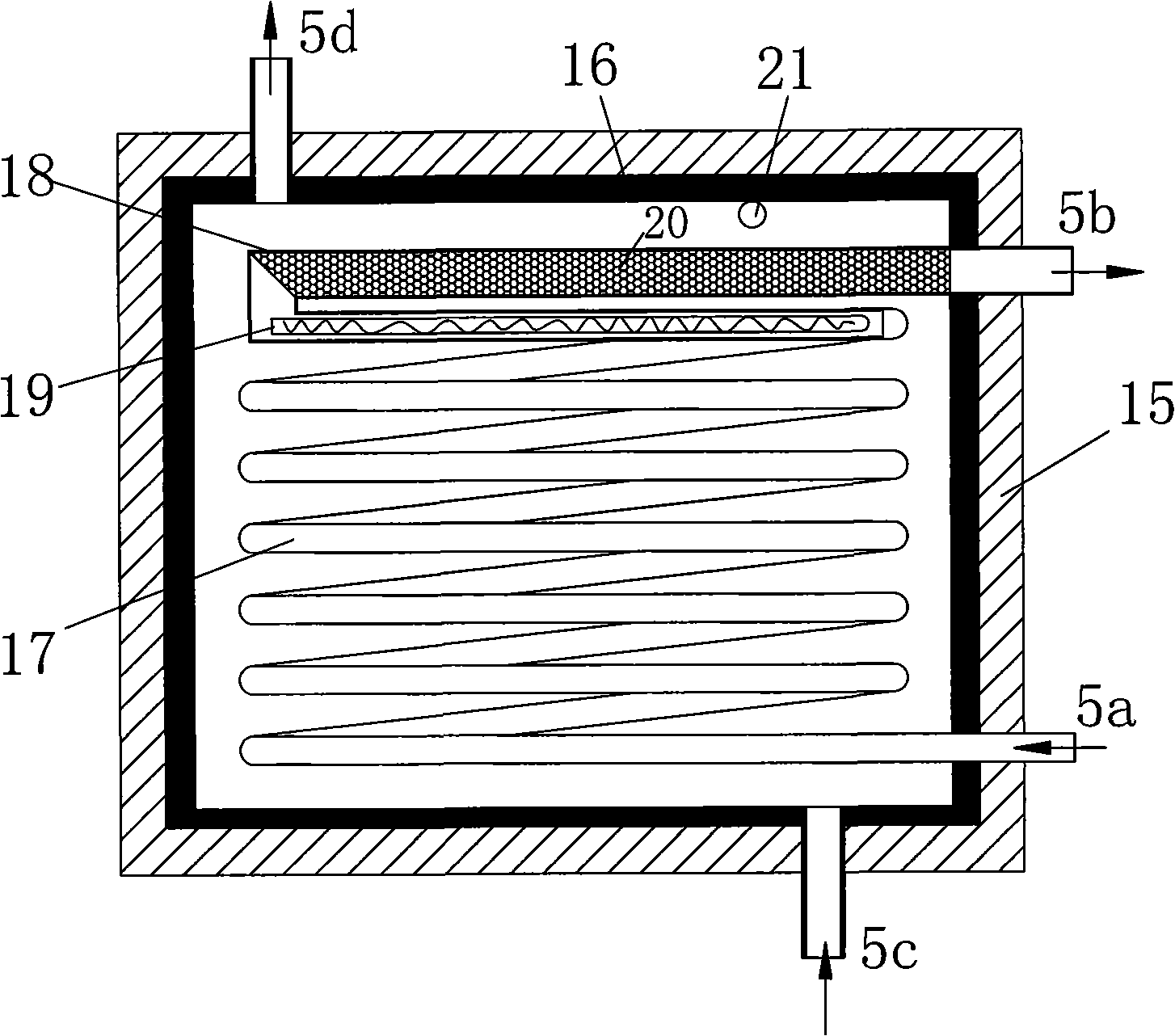

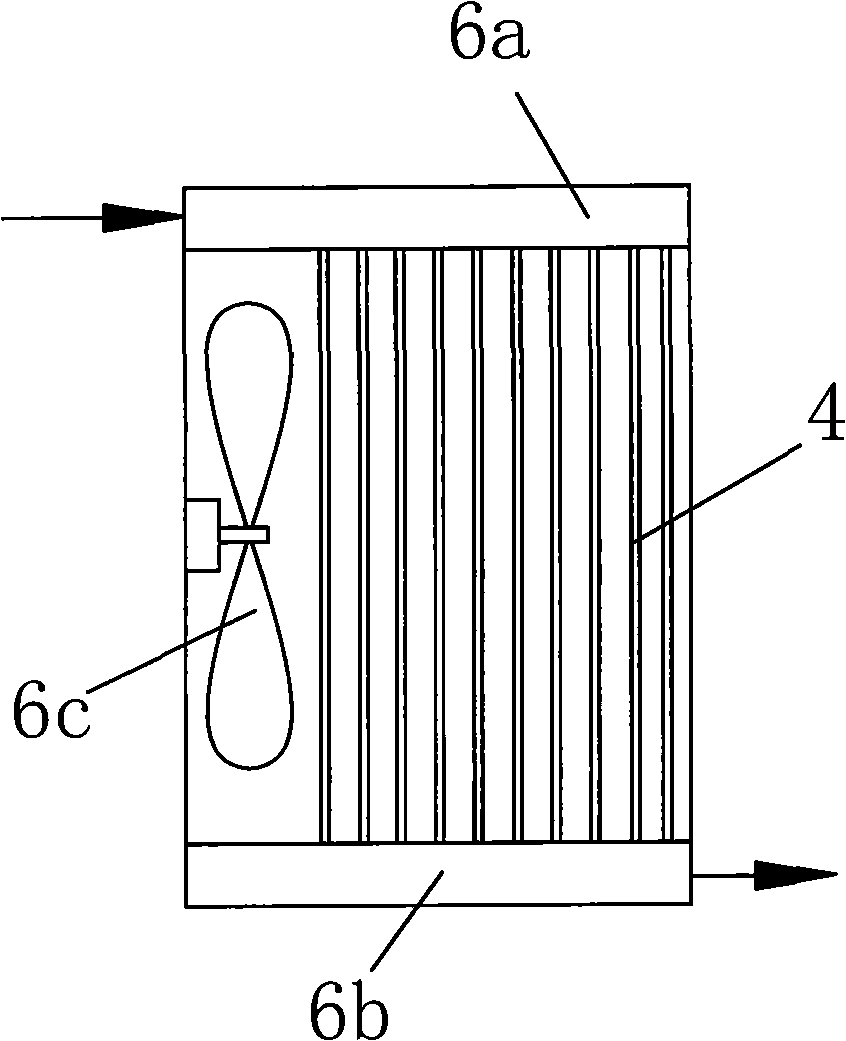

[0025] see figure 1 , this ammonia decomposition hydrogen production system based on heat engine exhaust waste heat, including liquid ammonia bottle 1, electronic control valve 2, vaporization chamber 22, heat exchanger 3, cooler 6, high-pressure air pump 8, high-pressure hydrogen storage bottle 7 and heating Cracker 5, their connections are as follows:

[0026] The gas outlet of the liquid ammonia bottle 1 is connected to the inlet of the vaporization chamber 22 through the electric control valve 2, and the outlet of the vaporization chamber 22 is connected to the tube side inlet 3a of the heat exchanger 3, and the tube side of the heat exchanger 3 The outlet 3b is connected with the first air inlet 5a of the heating cracker 5, the first gas outlet 5b of the heating cracker 5 is connected with the shell side inlet 3c of the heat exchanger 3, and the shell side outlet...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com