Coaxial polyphosphazene nanofiber composite membrane and preparation method thereof

A technology of nanofibers and polyphosphazene, which is applied in fiber processing, textiles, papermaking, non-woven fabrics, etc., can solve the limitations of the preparation and practical application of polyphosphazene nanofiber membranes, poor mechanical strength of nanofiber membrane materials, Difficult to obtain polyphosphazene nanofiber membrane and other problems, to achieve the effect of improving stability and mechanical strength, easy to obtain raw materials, and uniform shape

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

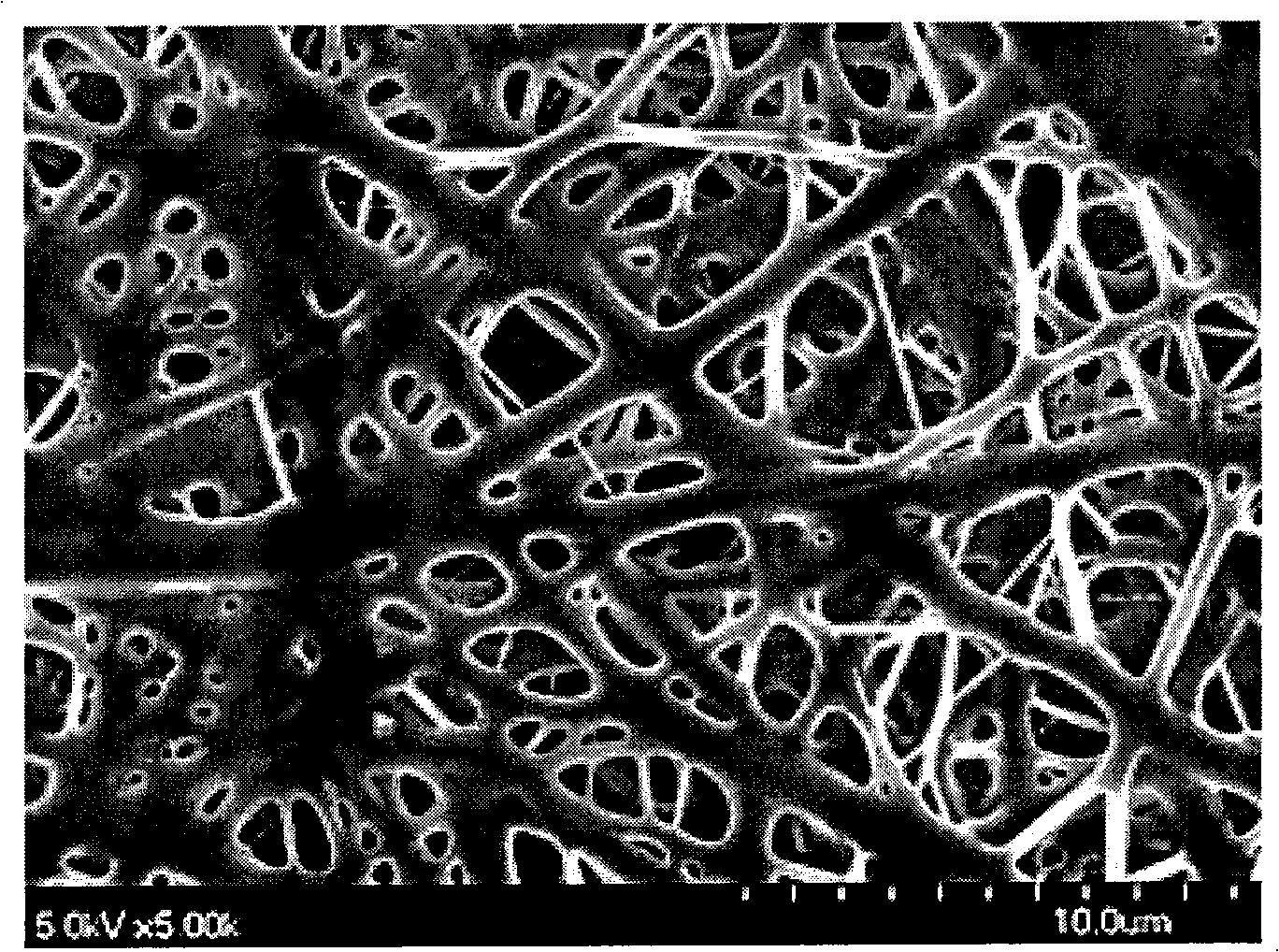

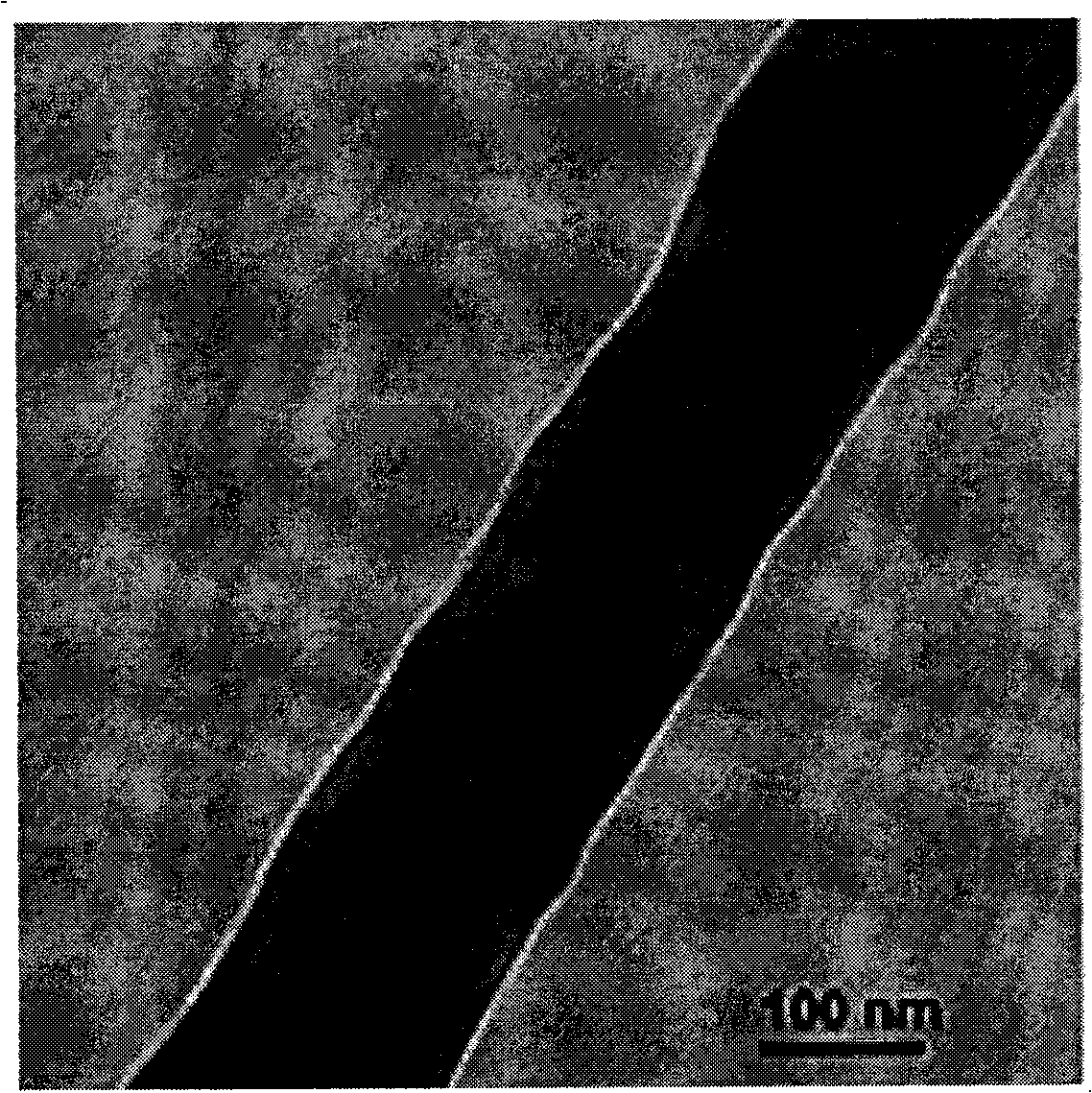

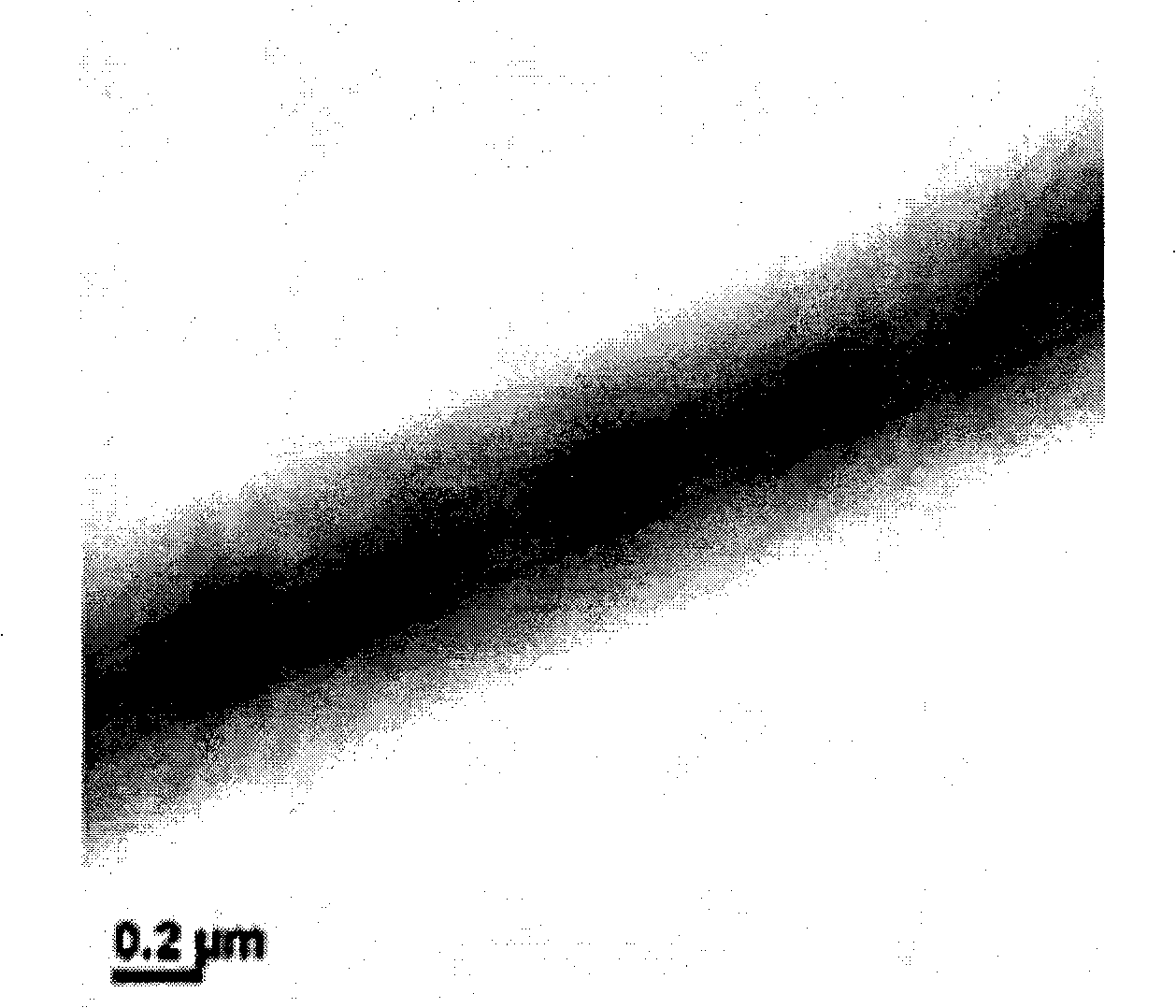

[0030] A coaxial electrospinning device is used to dissolve poly-p-methylphenoxyphosphazene with a molecular weight of 200,000 in N,N'-dimethylformamide to prepare poly-p-methylphenoxyphosphazene with a concentration of 25% by weight. phenoxyphosphazene solution, as the coaxial electrospinning outer layer spinning solution; polyacrylonitrile with a molecular weight of 50,000 is dissolved in dimethyl sulfoxide to form a polypropylene with a concentration of 25% by weight Nitrile solution, as the spinning solution for the inner layer of coaxial electrospinning; inject the polyacrylonitrile solution into the inner layer of the coaxial spinneret, and inject the poly-p-methylphenoxyphosphazene solution into the outer layer of the coaxial spinneret , adjust the flow rate of the outer layer spinning solution to be 1mL / h, the flow rate of the inner layer spinning solution to be 1mL / h, the receiving distance to be 15cm, and the spinning voltage to be 10kV, and carry out electrospinning ...

Embodiment 2

[0032]A coaxial electrospinning device is used to dissolve poly-p-methylphenoxyphosphazene with a molecular weight of 600,000 in N,N'-dimethylacetamide to prepare a poly-p-methylphenoxide with a concentration of 20% by weight. phenoxyphosphazene solution, as the coaxial electrospinning outer layer spinning solution; polyacrylonitrile with a molecular weight of 80,000 is dissolved in N, N'-dimethylformamide, and the concentration by weight is 20% polyacrylonitrile solution is used as the inner layer spinning solution of coaxial electrospinning; the polyacrylonitrile solution is injected into the inner layer of the coaxial spinneret, and the poly-p-methylphenoxyphosphazene solution is injected into the coaxial nozzle For the outer layer of the silk head, adjust the flow rate of the outer layer spinning solution to 0.8mL / h, the flow rate of the inner layer spinning solution to 0.8mL / h, the receiving distance to be 20cm, and the spinning voltage to be 15kV, and perform electrospinn...

Embodiment 3

[0034] Using a coaxial electrospinning device, dissolving poly-p-methylphenoxyphosphazene with a molecular weight of 1,000,000 in tetrahydrofuran to prepare a solution of poly-p-methylphenoxyphosphazene with a concentration of 15% by weight, as Coaxial electrospinning outer layer spinning solution; polyacrylonitrile with a molecular weight of 100,000 is dissolved in N, N'-dimethylacetamide to form a polyacrylonitrile solution with a concentration of 15% by weight, as Coaxial electrospinning inner layer spinning solution; injecting polyacrylonitrile solution into the inner layer of the coaxial spinneret, injecting poly-p-methylphenoxyphosphazene solution into the outer layer of the coaxial spinneret, and adjusting the outer layer The flow rate of the spinning solution is 0.5mL / h, the flow rate of the inner layer spinning solution is 0.5mL / h, the receiving distance is 25cm, and the spinning voltage is 18kV. Electrospinning is carried out to obtain polyacrylonitrile as the core an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Fiber diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com