Super absorbent soil reclamation plant growth substance and preparation method thereof

A soil quality improvement and high water absorption technology, applied in the field of plant cultivation substrate and its preparation, can solve the problems of low soil water content of plant cultivation substrate, unable to meet plant fertility factors, low plant survival rate, etc., and achieve fast fertilizer efficiency and improve plant survival. The effect of high rate and nutritional content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

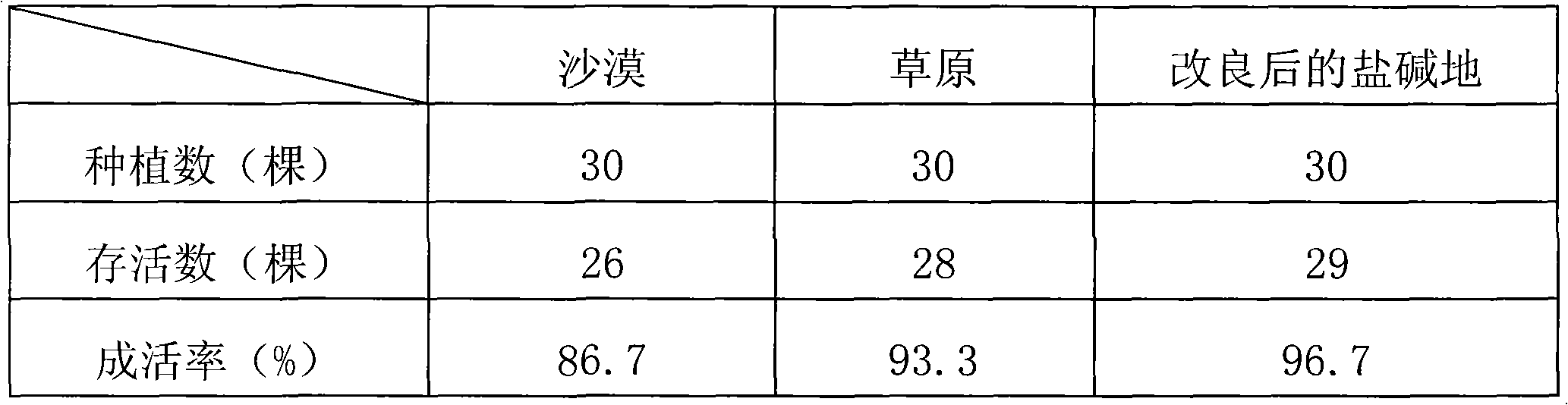

Examples

Embodiment 1

[0050] (1) prepare urea-formaldehyde foamed plastics:

[0051] Described urea-formaldehyde foam plastics is made up of following components by following parts by weight:

[0052]The urea-formaldehyde resin of 50 parts by weight, the sodium lauryl sulfate of 1.5 parts by weight, the phosphoric acid of 0.5 parts by weight, the oxalic acid of 0.5 parts by weight, the phenol of 0.15 parts by weight, the urea of 1 weight part, the magnesium chloride of 0.5 parts by weight, 48 parts by weight of water. The parts of water used to prepare the acid blowing agent are 14.112 parts, the parts of sodium lauryl sulfate are 0.735 parts, the parts of phenol are 0.075 parts, and the parts of urea are 0.5 parts. Among them, the parts of water used to prepare the acid-free foaming agent are 14.688 parts, the parts of sodium lauryl sulfate are 0.765 parts, the parts of phenol are 0.075 parts, and the parts of urea are 0.5 parts, which are used to dilute The parts of water in the urea-formalde...

Embodiment 2

[0065] (1) prepare urea-formaldehyde foamed plastics:

[0066] Described urea-formaldehyde foamed plastics is made up of following components by following weight:

[0067] 75kg of urea-formaldehyde resin, 0.1kg of sodium lauryl sulfate, 0.05kg of phosphoric acid, 0.1kg of oxalic acid, 0.01kg of phenol, 0.05kg of urea, 0.05kg of magnesium chloride, and 22kg of water. The weight of the water used to prepare the acid blowing agent is 6.468kg, the weight of sodium lauryl sulfate is 0.049kg, the weight of phenol is 0.005kg, and the weight of urea is 0.025kg. Wherein the weight that is used to prepare the water of acid-free blowing agent is 6.732kg, the weight of sodium lauryl sulfate is 0.051kg, the weight of phenol is 0.005kg, the weight of urea is 0.025kg, the water used for diluting urea-formaldehyde resin The weight is 8.8kg.

[0068] (2) The plant-promoting matrix for improving water-absorbing soil quality is composed of the following components by weight:

[0069] 70kg of ...

Embodiment 3

[0072] (1) described urea-formaldehyde foamed plastics is made up of following components by following weight:

[0073] 55kg of urea-formaldehyde resin, 0.3kg of sodium lauryl sulfate, 0.08kg of phosphoric acid, 0.2kg of oxalic acid, 0.03kg of phenol, 0.1kg of urea, 0.08kg of magnesium chloride, and 32kg of water. Wherein the weight that is used to prepare the water that has acid blowing agent is 9.408kg, the weight of sodium lauryl sulfate is 0.147kg, the weight of phenol is 0.015kg, the weight of urea is 0.05kg. Wherein the weight that is used to prepare the water of acid-free foaming agent is 9.792kg, the weight of sodium lauryl sulfate is 0.153kg, the weight of phenol is 0.015kg, the weight of urea is 0.05kg, the water used for diluting urea-formaldehyde resin The weight is 12.8kg.

[0074] (2) The plant-promoting matrix for improving water-absorbing soil quality is composed of the following components by weight:

[0075] 60kg of urea-formaldehyde foam; 40kg of straw pow...

PUM

| Property | Measurement | Unit |

|---|---|---|

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com