Boron selective gel adsorbent containing polyhydroxy functional groups, preparation and application thereof

A polyhydroxyl functional and selective technology, applied in adsorption water/sewage treatment, other chemical processes, chemical instruments and methods, etc., can solve the problem of poor adsorption capacity and selectivity of non-specific adsorbents, complex preparation process of boron-specific adsorption resins, Unsatisfactory mechanical strength and other problems, to achieve the effect of easy industrial application, small shrinkage and expansion, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

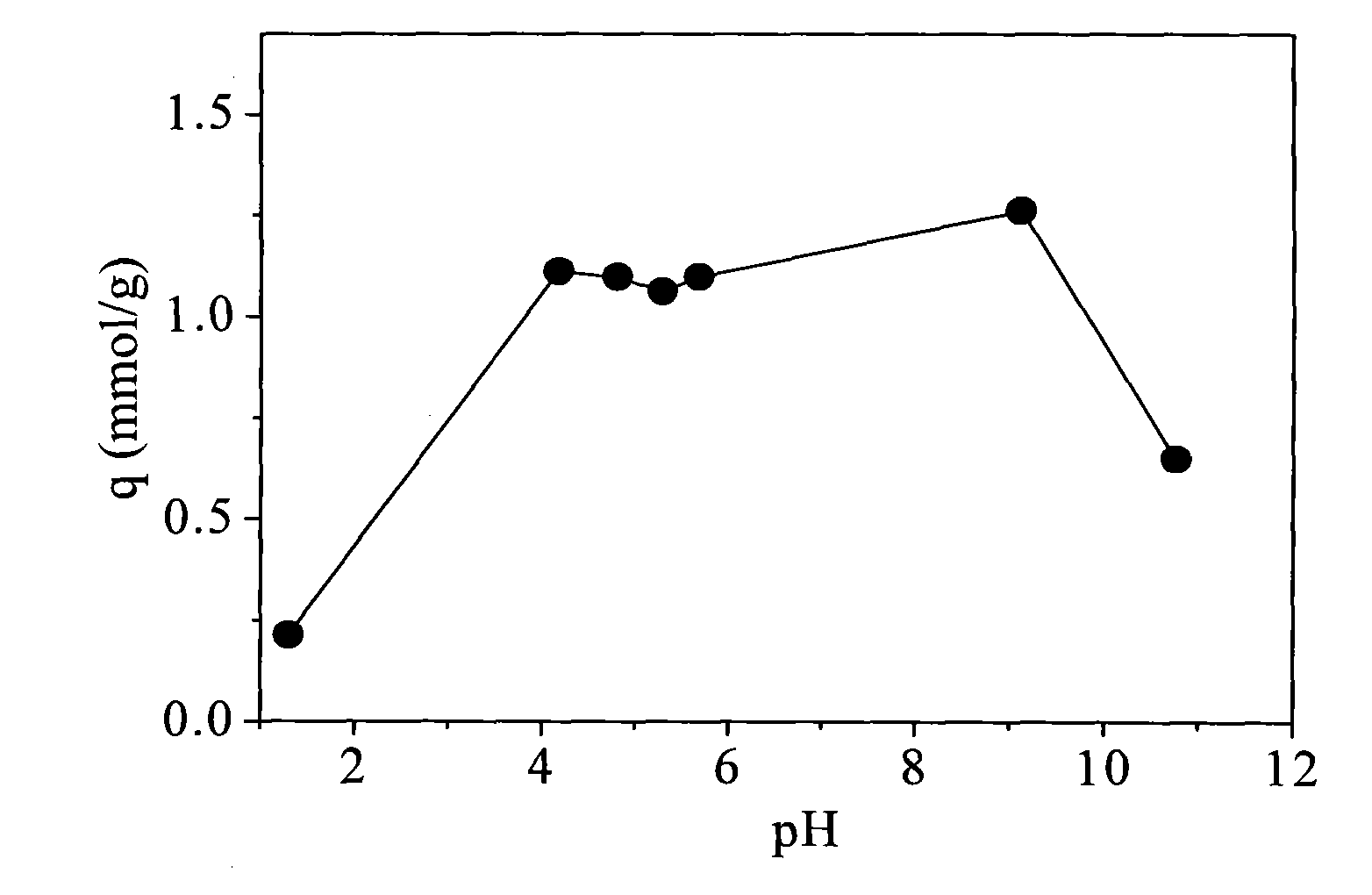

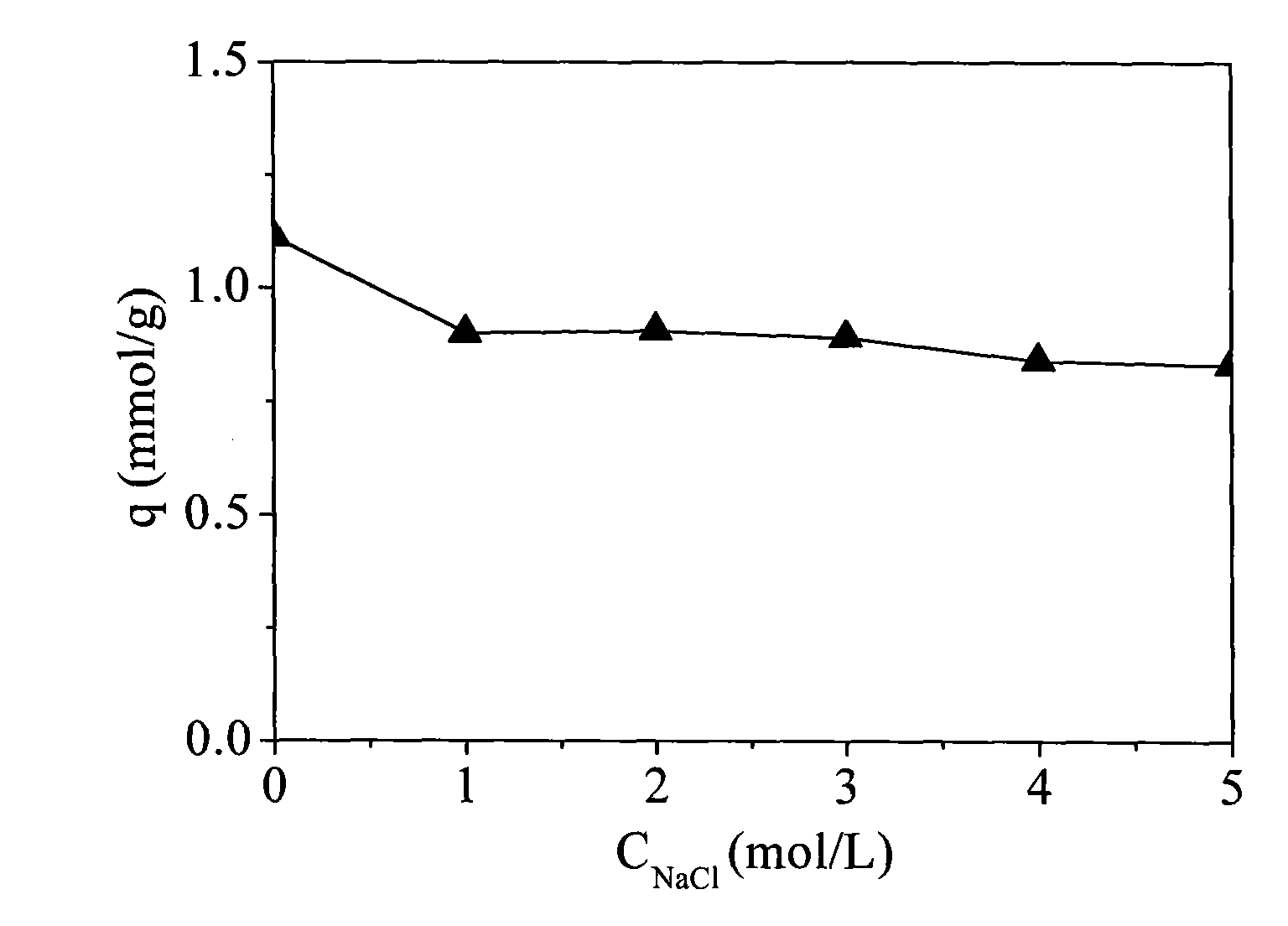

[0030] Γ-glycidoxypropyltrimethoxysilane and ethyl orthosilicate were selected as the organic silicon raw materials, and N-methylglucamine was selected as the compound containing polyhydroxyl groups.

[0031] Weigh 19.5g of N-methylglucamine and 24mL of γ-glycidoxypropyltrimethoxysilane in 100mL of N,N-methylformamide solvent, stir and react at 50~80℃ for 4h to obtain Hydroxyl functional group gel precursor. The obtained gel precursor was washed with ethanol and dried at 30°C to obtain 112 g of solid which can be used for the synthesis of gel adsorbent. The preparation process of the polyhydroxy-containing gel precursor is as follows:

[0032]

[0033] Among them GPTMS-γ-glycidoxypropyl trimethoxysilane

[0034] MG-N-Methyl Glucosamine

[0035] W-gel precursor

[0036] DMF——N,N-Methylformamide

[0037]Dissolve the gel precursor prepared above in 50 mL of water, add 50 mL of tetraethyl orthosilicate, and stir continuously. After the system is uniform, add 10 mL of 2mol / L hydrochl...

Embodiment 2

[0043] Choose γ-glycidoxypropyltrimethoxysilane and ethyl orthosilicate as the gel raw materials, and N-methylglucosamine as the compound containing polyhydroxy groups. The gel is obtained first and then the polyhydroxy compound is used. The reaction method prepares the adsorbent.

[0044] Mix 24mL of γ-glycidoxypropyltrimethoxysilica with 50mL of ethyl orthosilicate and 50mL of water. After the system is uniform, add 10mL of 2mol / L hydrochloric acid, stir and hydrolyze for 2h, add 10mL of 5mol / L of ammonia, Stir vigorously until it is gelled and age it for 12h, dry at 30℃, pulverize through a 20-60 mesh sieve, then wash several times, and then dry at 30℃, the obtained dry gel is used to prepare polyhydroxy functional groups Boron selective gel adsorbent.

[0045] The obtained gel and 19.5g N-methylglucosamine were stirred and reacted at 50~80℃ for 4h in 100mL N,N-methylformamide solvent to obtain a gel containing polyhydroxy functional groups, which was washed with ethanol , Drie...

Embodiment 3

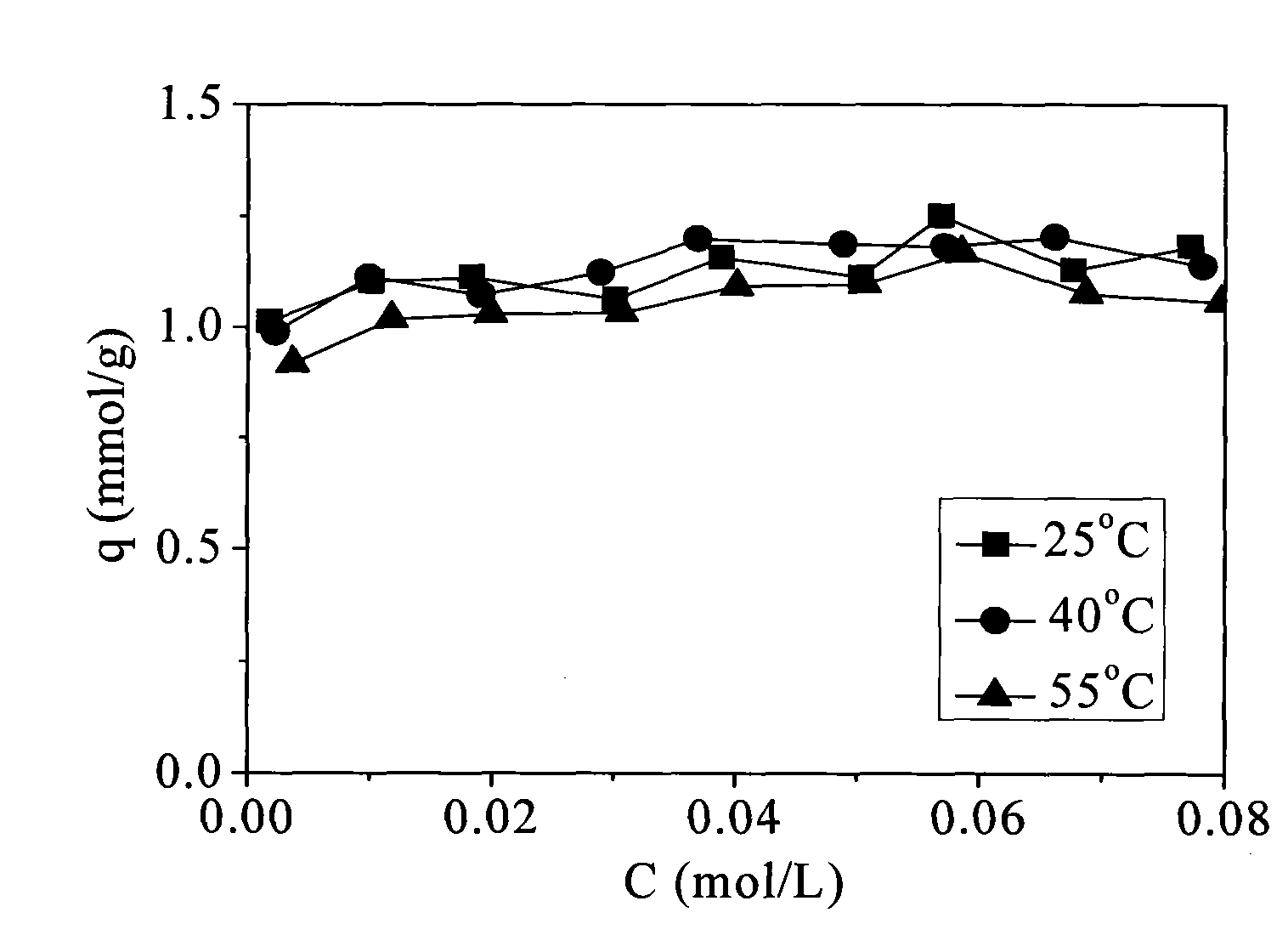

[0048] Γ-(methacryloyloxy)propyl trimethoxy silicon and ethyl orthosilicate were selected as the organic silicon raw materials, and glucosamine was selected as the compound containing polyhydroxyl groups.

[0049] Weigh 18.0g glucosamine and 23.8mL γ-(methacryloyloxy)propyl trimethoxy silicon, and stir and react for 4h at 70~110℃ in 100mL N,N-methylformamide solvent to obtain Gel precursor containing polyhydroxy functional groups. The obtained gel precursor was washed with ethanol and dried at 30°C to obtain 108 g of solid, which can be used for the synthesis of gel adsorbent. The preparation process of polyhydroxy-containing gel precursor is shown in the figure below:

[0050]

[0051] Among them GPTMS-γ-(methacryloyloxy) propyl trimethoxy silicon

[0052] AG-Glucosamine

[0053] W′——gel precursor

[0054] DMF——N,N-Methylformamide

[0055] Dissolve the gel precursor 2 prepared above in 50 mL of water, add 50 mL of tetraethyl orthosilicate, and keep stirring. After the system is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com