Small-scale magnesium alloy bar pipe hot extrusion shaping mold

A molding die and magnesium alloy technology, applied in the direction of metal extrusion dies, etc., can solve the problems of large wall thickness difference, low production efficiency, and many forming processes, etc., and achieve uniform deformation of the billet, low production cost, and simple mold structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

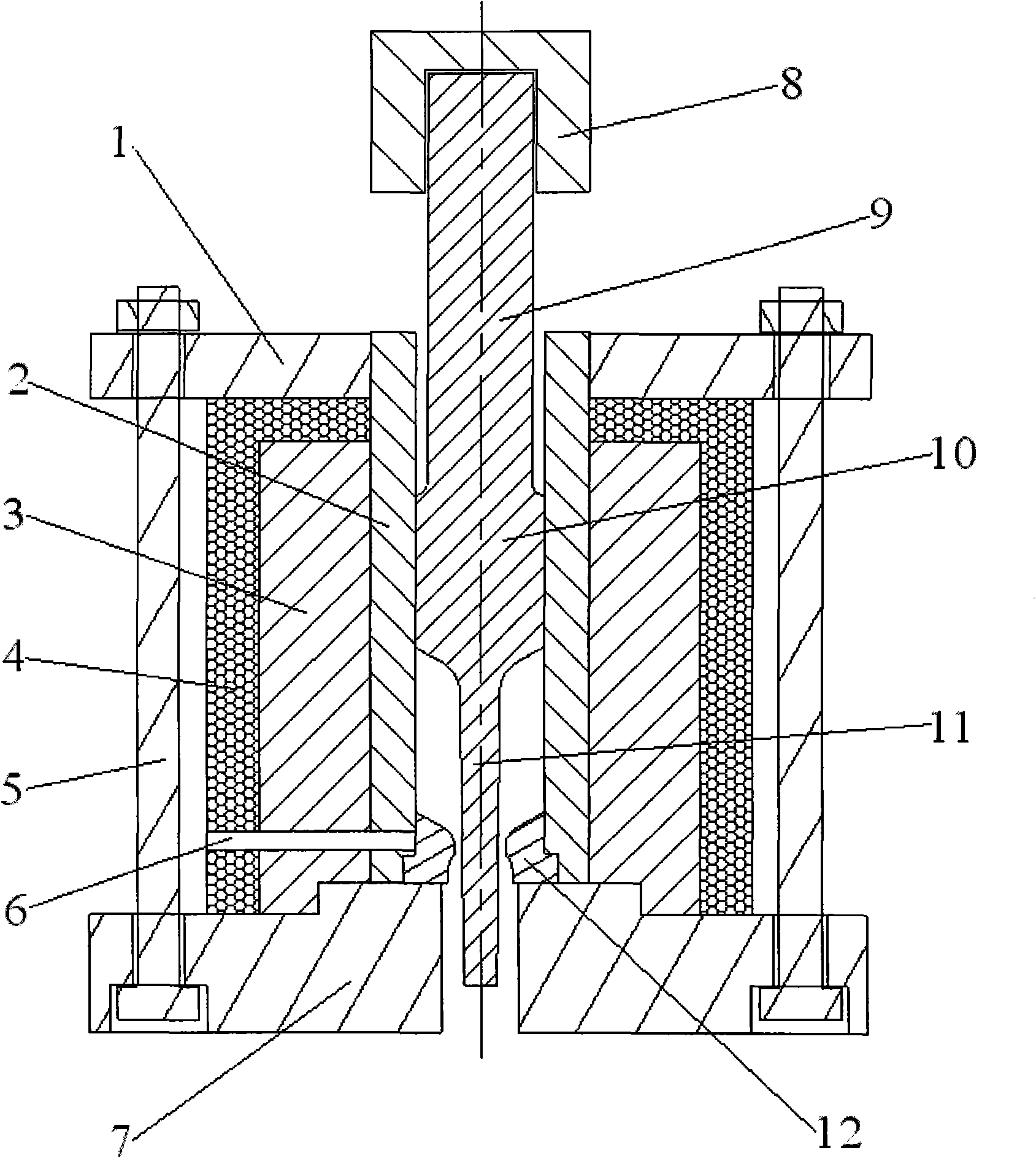

[0032] Embodiment 1 (the extruded external diameter of this embodiment is 8mm, and the magnesium alloy thin-walled tubule of internal diameter is 6mm)

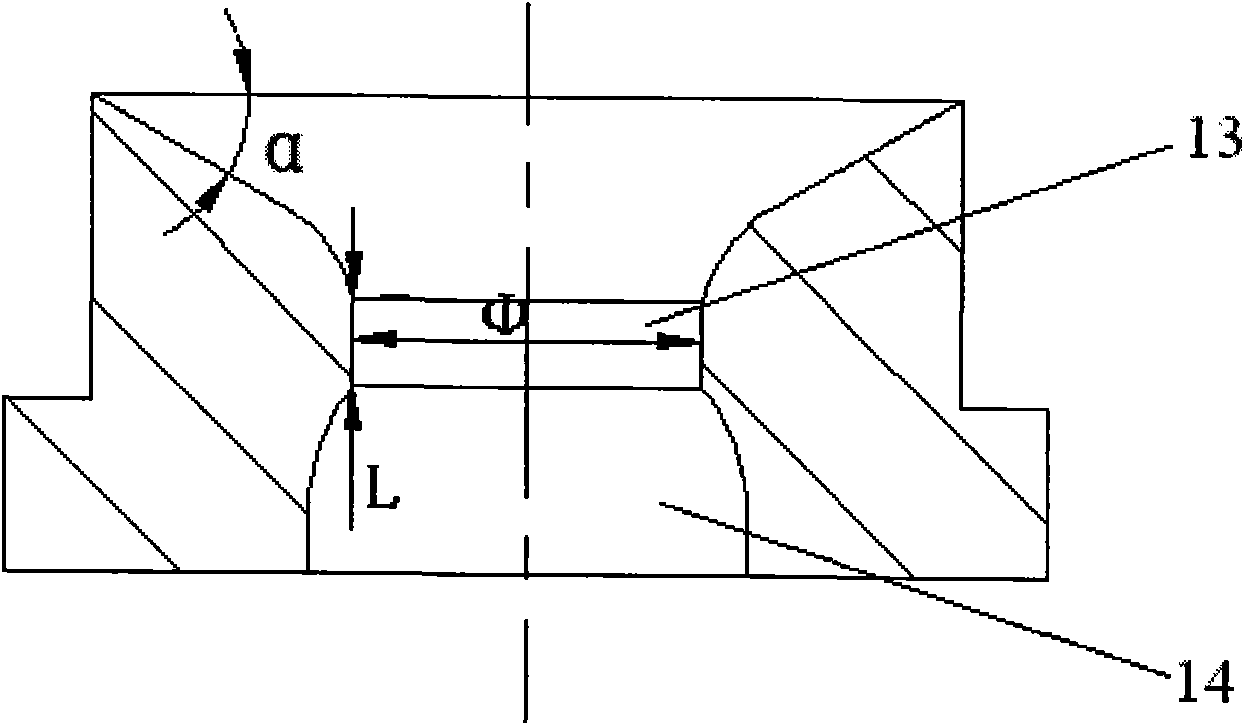

[0033] The mold structure used in this embodiment is as follows figure 1 As shown, the inner diameter of the extrusion cylinder lining 2 is 20mm, the diameter of the extrusion needle 11 is 6mm, and the diameter of the cavity of the die 12 is 8mm. The die extrusion process is as follows:

[0034] (1) Machining is used to turn the magnesium alloy billet into a hollow cylinder with an outer diameter of 19.9mm and an inner diameter of 6.1mm, remove debris and burrs, and evenly coat lubricant on the inner and outer surfaces; After cleaning the inner wall of the pressure cylinder liner 2, evenly apply lubricant.

[0035] (2) The extrusion cylinder liner 2 fixes the die 12 on the lower mold base 7 through cooperation, and the extrusion needle 11 of the punch passes through the inner hole of the hollow billet, and is placed in the extr...

Embodiment 2

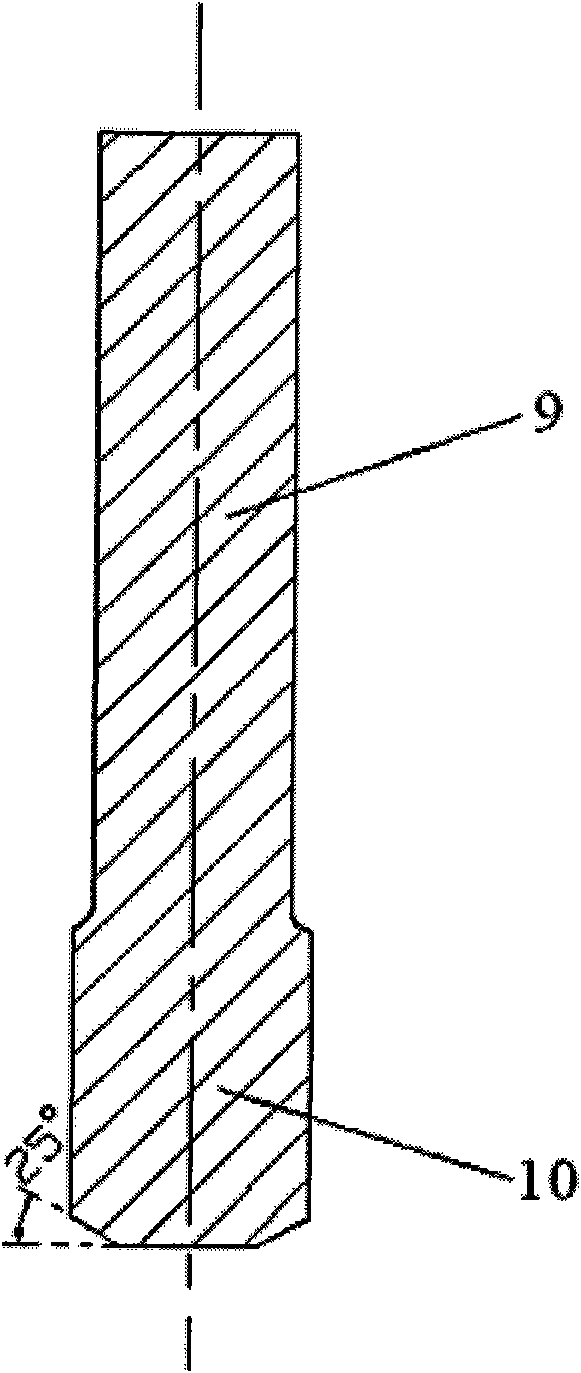

[0039] Embodiment 2 (the present embodiment extrusion diameter is the magnesium alloy bar of 8mm)

[0040] The mold structure used in this embodiment is only figure 1 The middle punch is replaced by figure 2 The punch shown will do. The assembly and extrusion process of the mold is completely similar to that of Example 1, except that the billet is machined into a cylinder with a diameter of 19.9 mm, coated with a lubricant, directly loaded into the extrusion cylinder, and pressed onto the punch for extrusion.

[0041] The extrusion force in the extrusion process of this embodiment is very small, and the maximum extrusion force is only 98KN. The conical remainder is about 2% of the billet. The obtained thin rods of magnesium alloy have a smooth surface, and the extruded rods are as follows: Figure 5 shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com