Method for electrolyzing and recovering hexavalent chrome in chromium-electroplating waste water

A technology of electrolytic recovery and electrochromium plating, which is applied in metallurgical wastewater treatment, chemical instruments and methods, water/sewage treatment, etc., can solve the problem that chromium cannot be reused, achieve low operating costs, low equipment investment, and good economic benefits Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

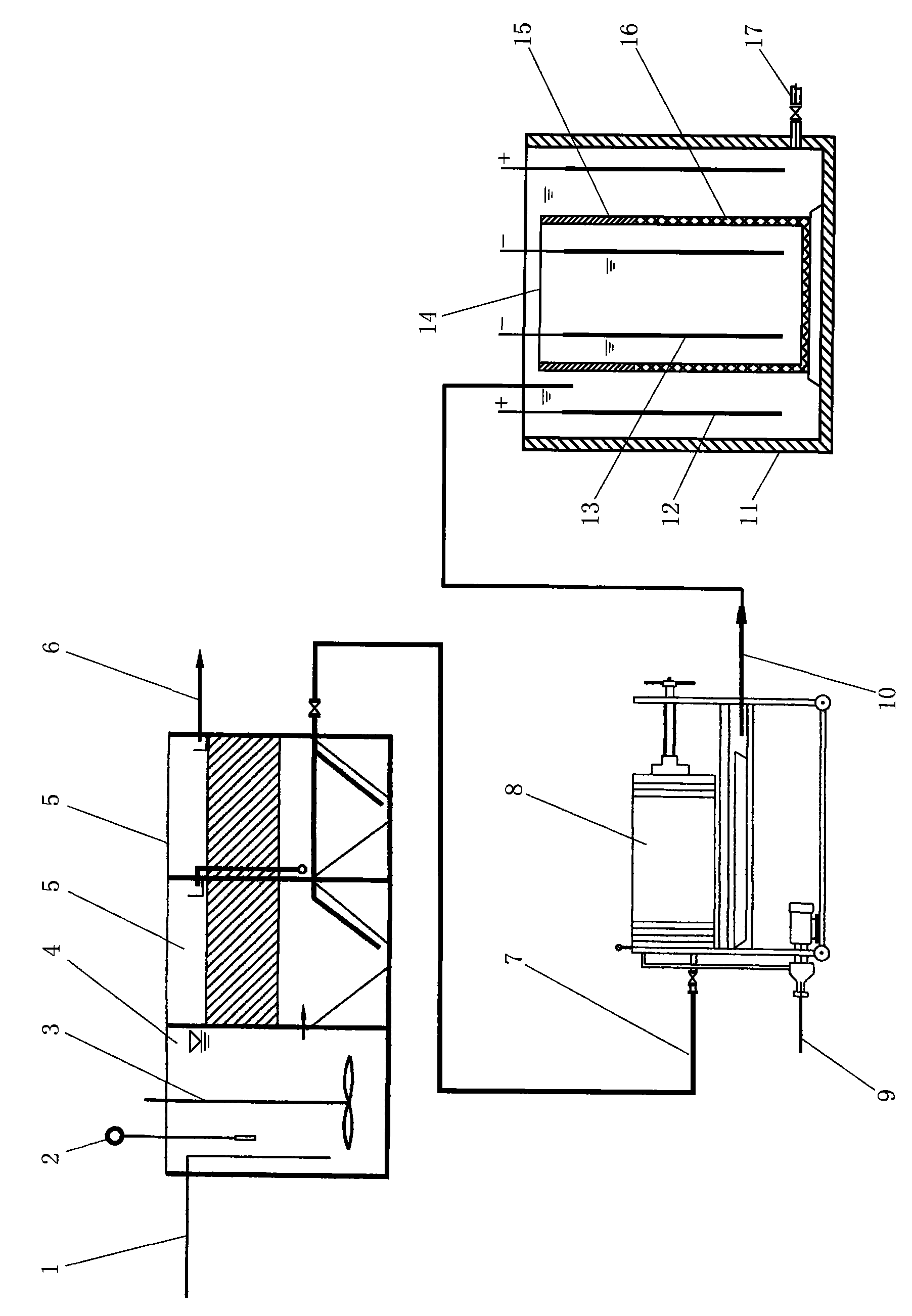

[0020] The present invention will be further described through the embodiments below with reference to the accompanying drawings.

[0021] Refer to attached figure 1 , a method for electrolytic recovery of hexavalent chromium in electrochrome plating wastewater, it comprises the following steps:

[0022] (1) Electrochrome plating waste water is injected in the reactor 4 through liquid inlet pipe 1, and sulfuric acid solution is added in electrochrome plating waste water under stirring, makes the pH value of electrochrome plating waste water be 1.0~1.3;

[0023] (2) Add sodium pyrosulfite to the chromium electroplating wastewater, the amount of sodium pyrosulfite added is 3.5 to 6 times that of hexavalent chromium, so that the oxidation-reduction potential of the electrochrome plating wastewater is below 220mv, and when the trivalent chromium salt begins to precipitate, then Add sodium carbonate solution to make the pH value of the chromium plating wastewater be 8.0 to 8.5;

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com