Micro-net component with rotary mobile micro-net body distributed with shock absorption and continuous line-shaped backwash

A technology for backwashing and backwashing pipes, which is applied in sustainable biological treatment, water/sludge/sewage treatment, biological water/sewage treatment, etc., and can solve the problems of membrane area limitation, difficulty in ensuring water quality, and adverse effects of dynamic membranes. , to achieve the effect of solving the uneven generation, improving the flux of the treated water, and eliminating the adverse effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

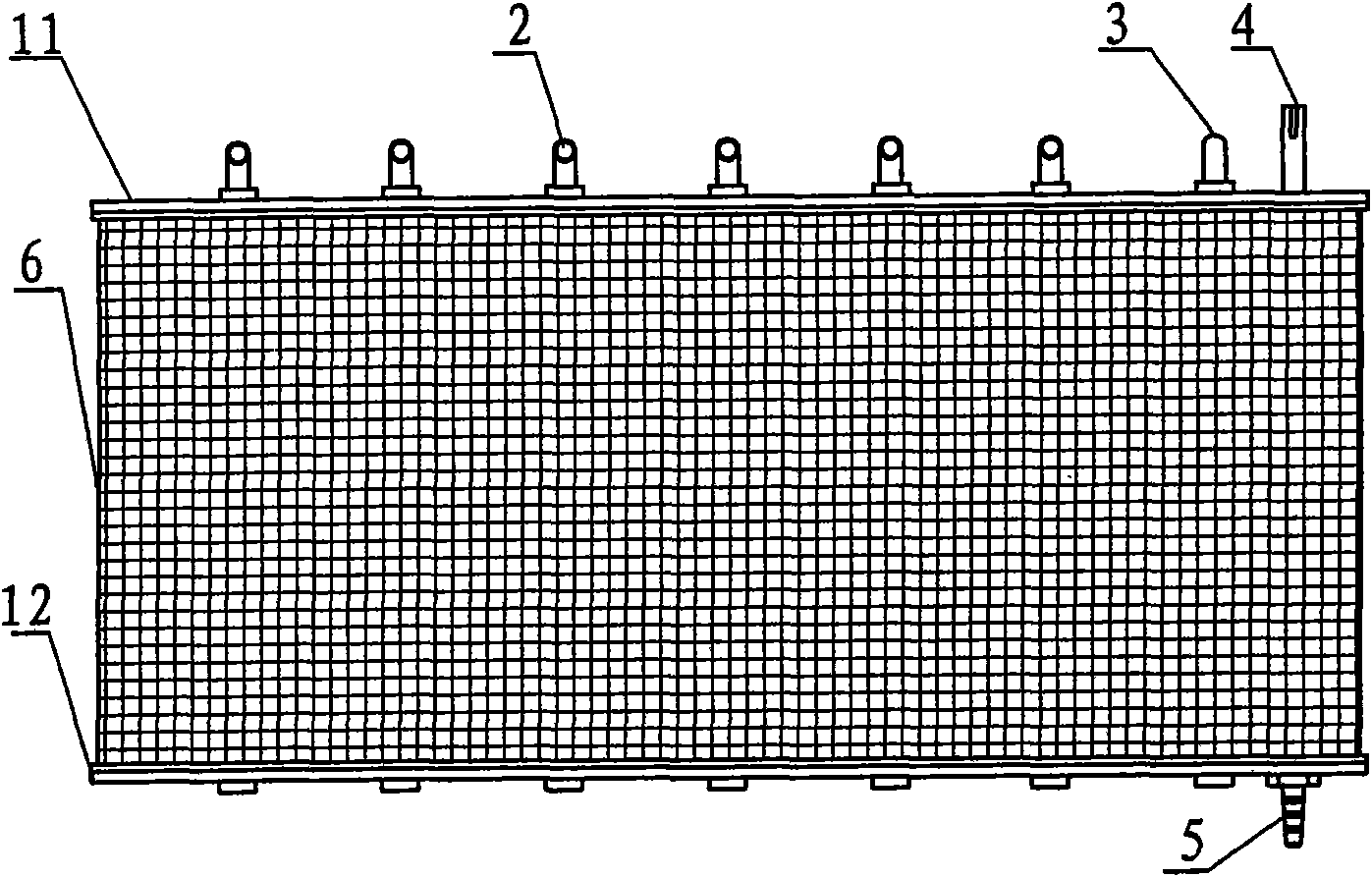

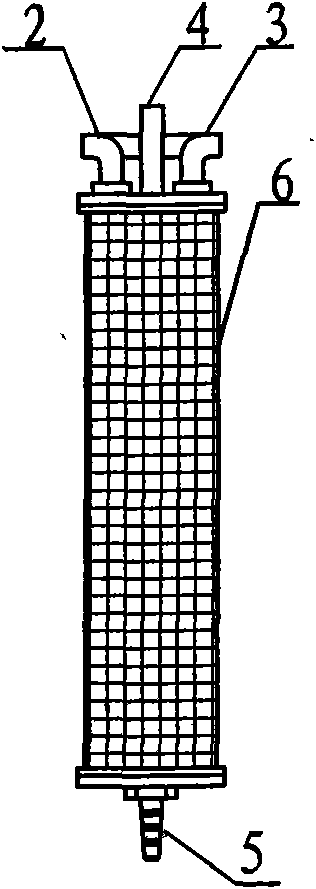

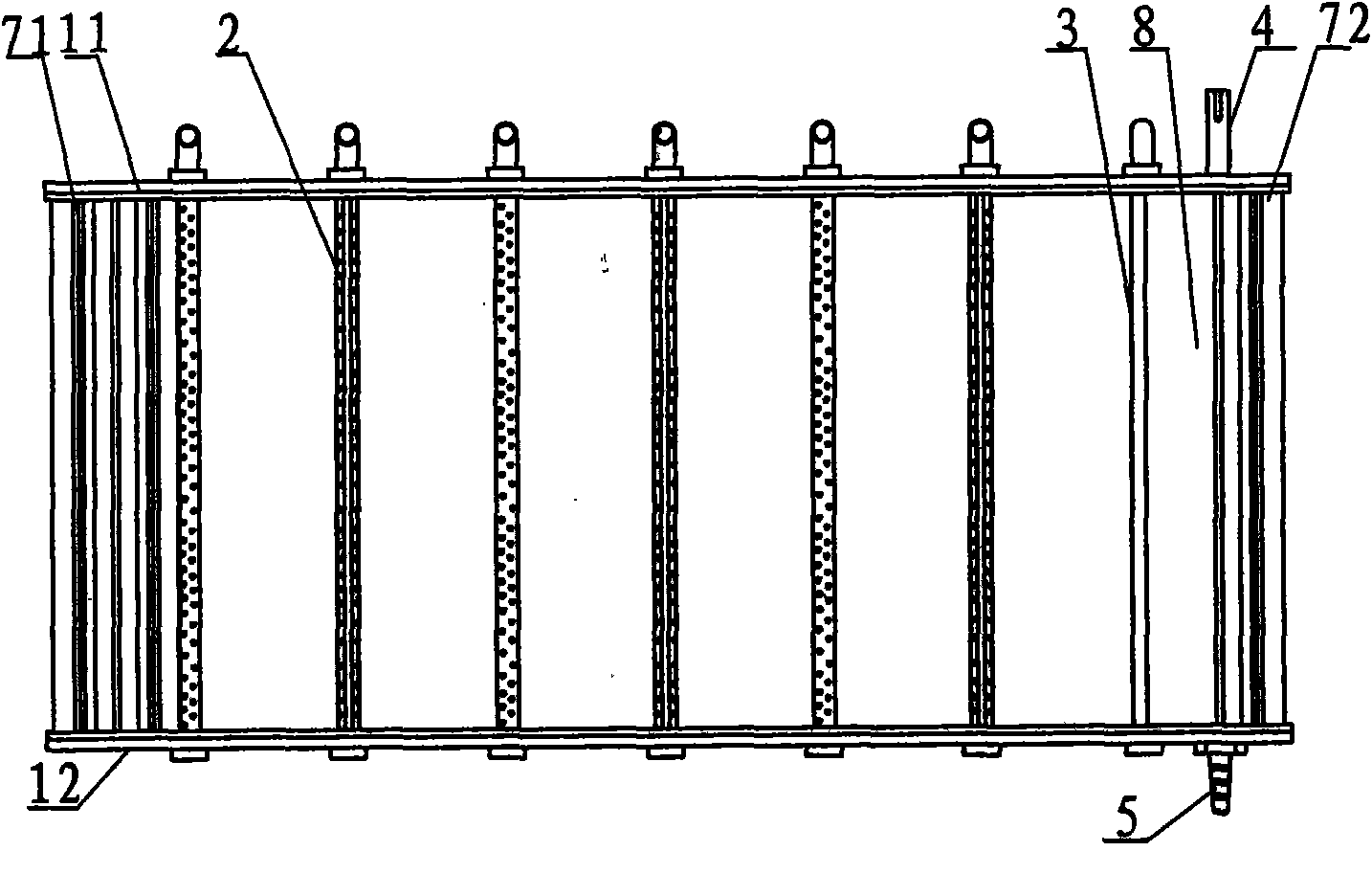

[0020] Figure 1~Figure 8 Shows a rotating mobile micro-mesh body distributed vibration reduction and continuous linear backwashing micro-mesh assembly and its application. The micro-mesh assembly includes a micro-mesh box body 1 and a back-flushing tube 3, characterized in that the micro-mesh box body 1 It consists of horizontal upper and lower cover plates 11 and 12 made of rigid impermeable material, left and right rollers 71 and 72 of squirrel-cage shape, curved baffle 8, multiple water collection pipes with convex wings 2 and micro-nets for collecting clean water The above-mentioned upper and lower cover plates 11, 12 are strip plates with semi-circular ends with symmetrical structure. The left and right ends of the two plates are vertically equipped with the above-mentioned freely rotatable left and right rollers. 71 and 72, one of the left and right rollers is connected to the driving mechanism. In this example, the right roller is connected to the driving mechanism through...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com