Preparation method of sludge absorber and applications thereof

A sludge adsorption and sludge technology, applied in chemical instruments and methods, adsorbed water/sewage treatment, water/sludge/sewage treatment, etc., can solve the problems of arsenic pollution control and removal in water phase without sludge adsorbent , to achieve the effect of resource utilization, low cost and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

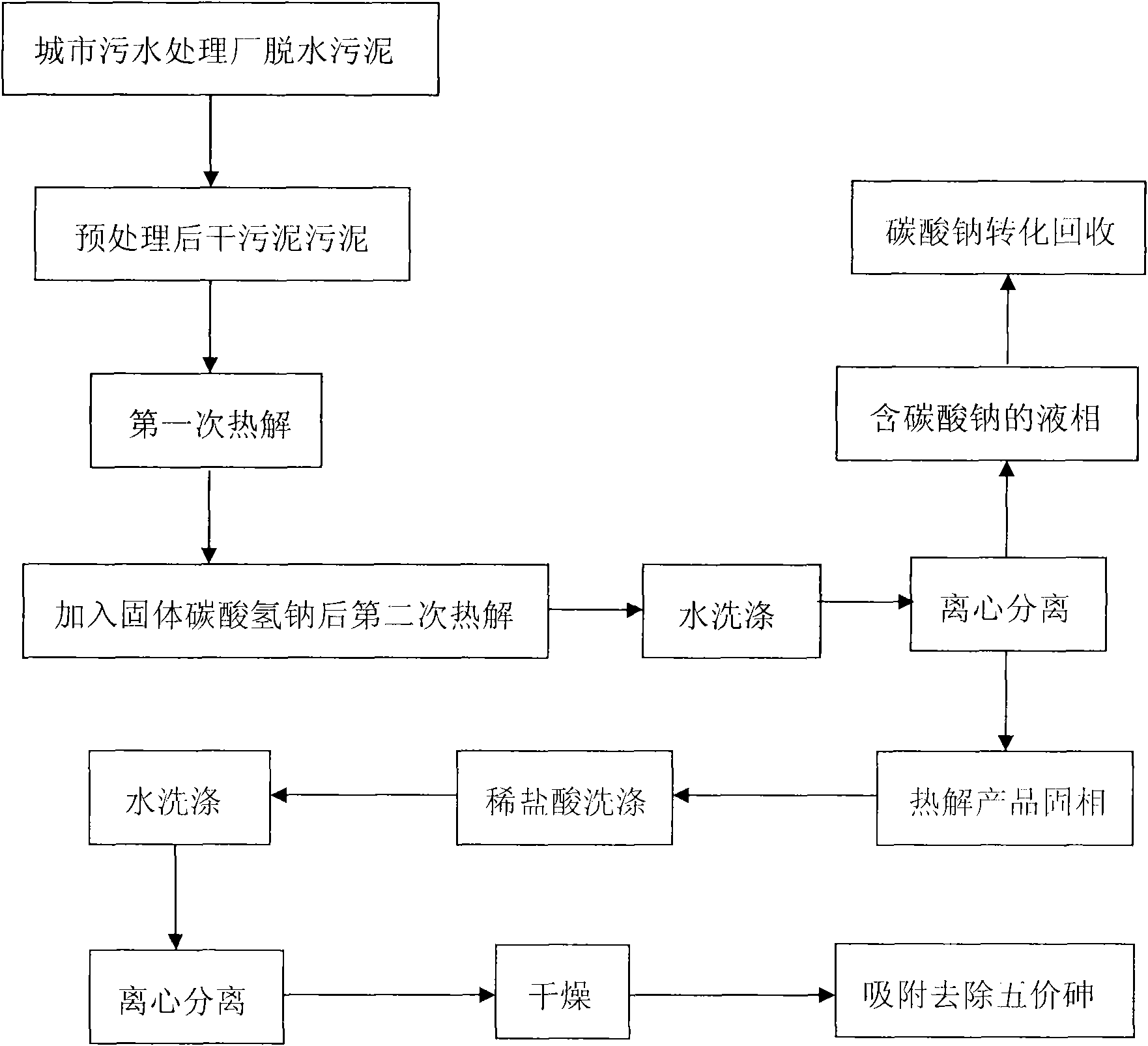

[0022] (1) Take the dewatered sludge from the urban sewage treatment plant, put it in a cool and dry place for 15 days, air-dry it, pass it through a 60-mesh sieve after grinding, put the sieved dry sludge in a tubular resistance furnace, and pass it through a nitrogen atmosphere for 30 minutes The heating time is specified, pyrolyzed at 500°C for 30 minutes, and then cooled to room temperature to obtain the first pyrolysis product of sludge.

[0023] (2) Mix the first pyrolysis product of the sludge with industrial-grade solid sodium bicarbonate, the mass ratio of the sodium bicarbonate and the first pyrolysis product of the sludge is 0.5:1, and stir evenly. The above solid mixture was placed in a tube-type resistance furnace again, and after a heating time of 30 minutes in a nitrogen atmosphere, it was pyrolyzed at 800° C. for 30 minutes, and cooled to room temperature to obtain the second pyrolysis product of sludge.

[0024] (3) Firstly, the second pyrolysis product of the...

Embodiment 2

[0027] (1) Take the dewatered sludge from the urban sewage treatment plant, put it in a cool and dry place for 15 days to air-dry, pass through a 60-mesh sieve after grinding, and place the sieved dry sludge in a tubular resistance furnace for 120 minutes in a nitrogen atmosphere Pyrolysis at 600°C for 30 minutes, and then cooled to room temperature to obtain the first pyrolysis product of sludge.

[0028] (2) Mix the first pyrolysis product of the sludge with industrial-grade solid sodium bicarbonate, the mass ratio of the sodium bicarbonate and the first pyrolysis product of the sludge is 1:1, and stir evenly. The above solid mixture was placed in a tube-type resistance furnace again, and after a heating time of 120 minutes in a nitrogen atmosphere, it was pyrolyzed at 650° C. for 120 minutes, and cooled to room temperature to obtain the second pyrolysis product of sludge.

[0029] (3) Firstly, the second pyrolysis product of the sludge is washed with water, and the solid ph...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com