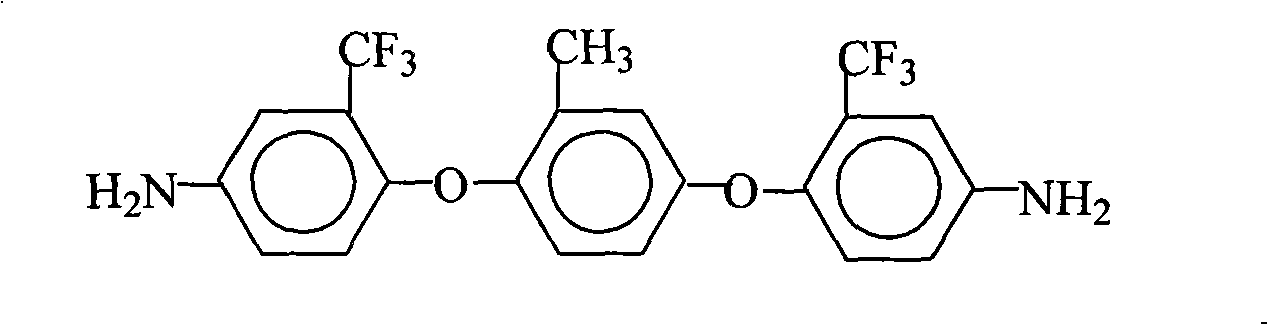

Preparation method of 2,5-bi(2-trifluoromethyl-4-aminophenoxyl)toluene

A technology of aminophenoxy and trifluoromethyl, which is applied in the field of preparation of aromatic fluorine-containing organic compounds, and achieves the effect of convenient source of raw materials, simple operation, and fewer types of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

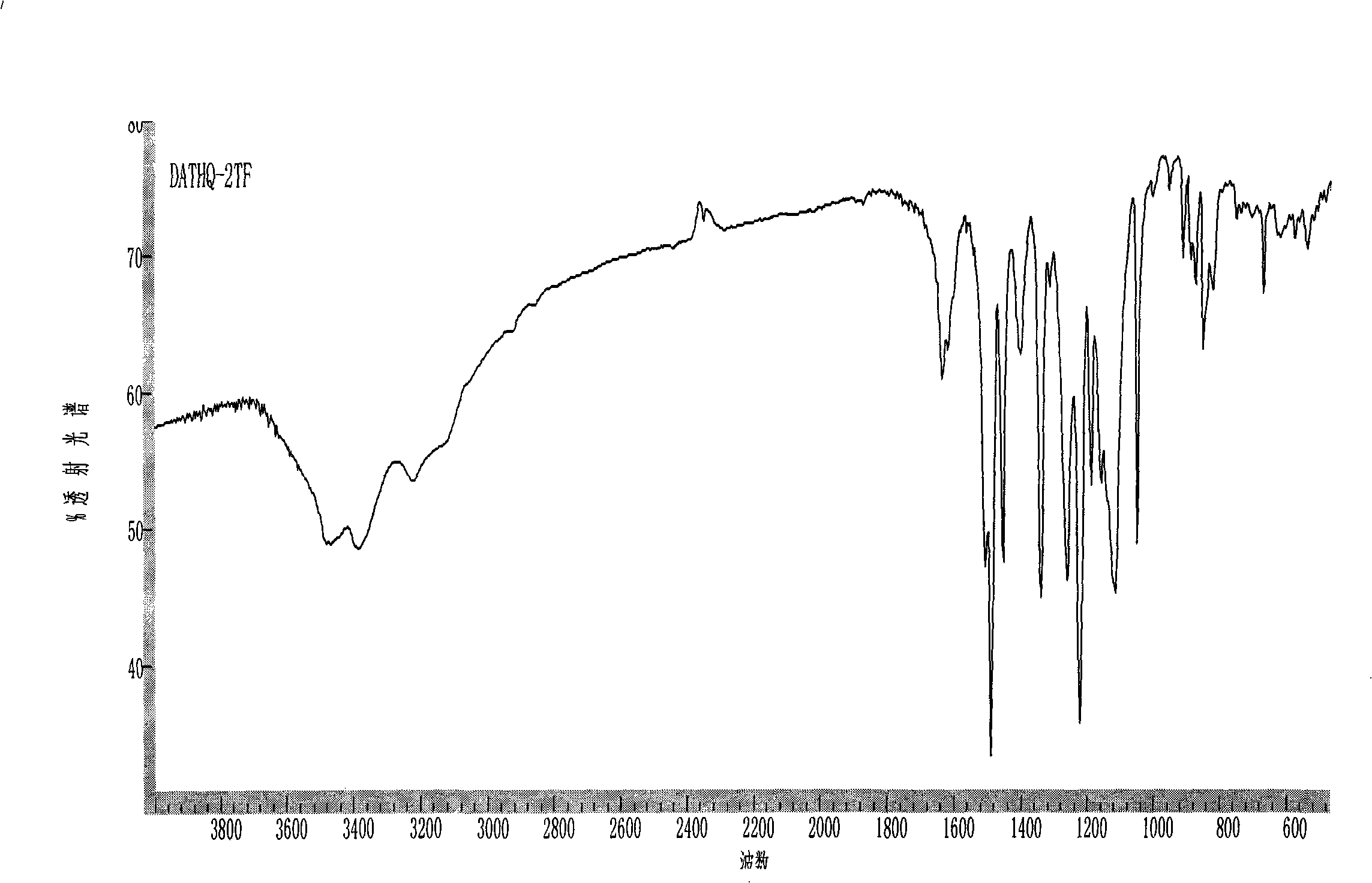

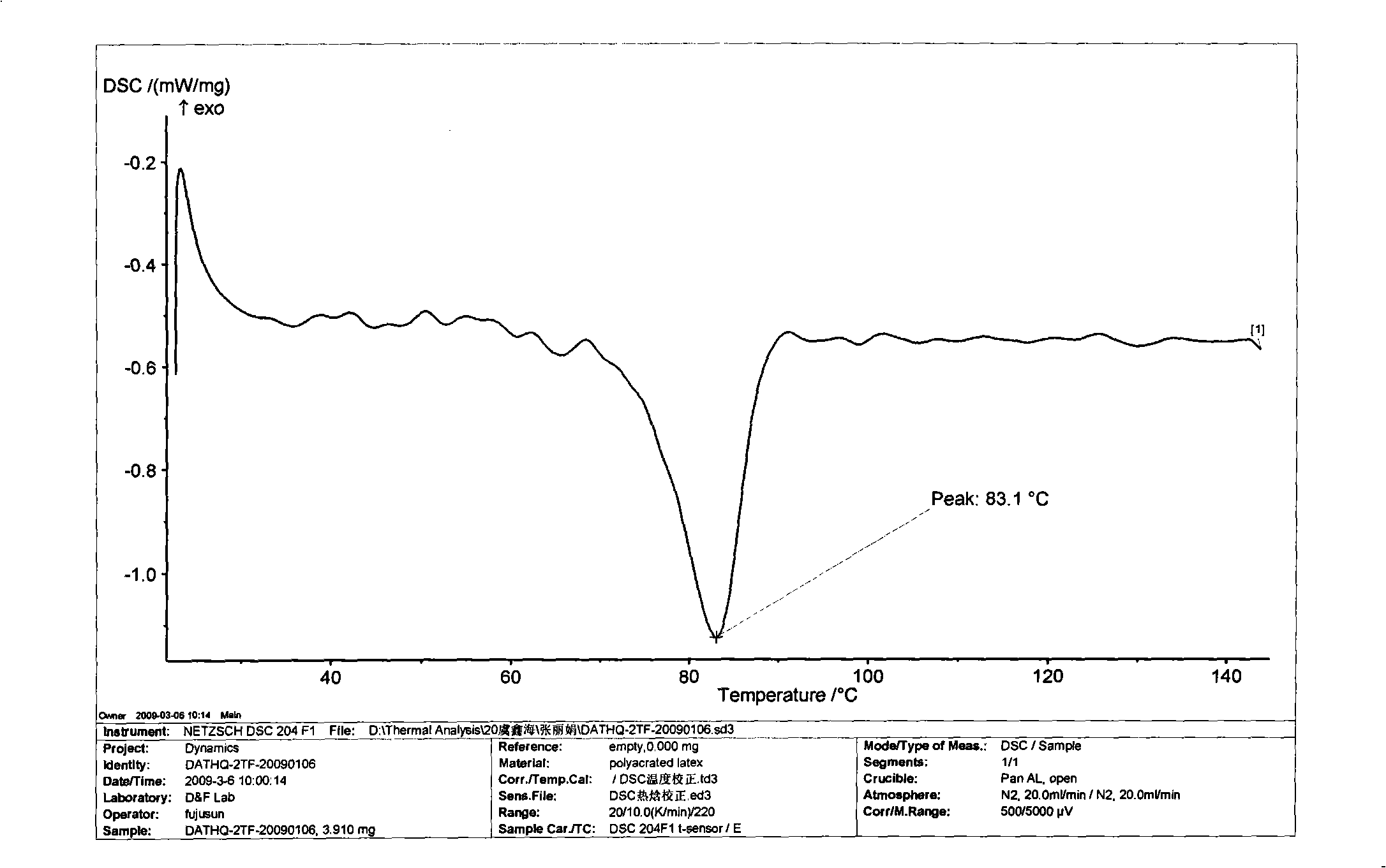

[0033] With 47.4 grams (0.10 mole) 2,5-bis(2-trifluoromethyl-4-nitrophenoxy) toluene, 710 milliliters of ethanol solvent, 2.8 grams of palladium / carbon (the mass percent of metal palladium is 10 %) catalyst into the reactor, heating, stirring, heating up to 70 ℃ ~ 80 ℃, dropwise adding 112.6 grams of hydrazine hydrate aqueous solution with a mass percentage concentration of 80%, the dropping time is strictly controlled at 1-1.5 hours, after the dropping is completed , keep the reaction at 70℃~80℃ for 3 hours, filter while it is hot, remove the filter residue, keep the mother liquor, and add 500ml of deionized water dropwise to the mother liquor while stirring, let it stand for 8 hours, and precipitate a white solid product , filtered, washed 2-3 times with deionized water, and dried to obtain 40.5 grams of 2,5-bis(2-trifluoromethyl-4-aminophenoxy)toluene solid (theoretical yield: 41.4 grams), melting point 83.1 ℃ (DSC method, nitrogen atmosphere, heating rate 10 ℃ / min), purity...

Embodiment 2

[0037] 47.4 grams (0.10 moles) of 2,5-bis(2-trifluoromethyl-4-nitrophenoxy) toluene, 74 milliliters of ethylene glycol and 400 milliliters of ethanol solvent, 4.7 grams of palladium / carbon (the mass of metal palladium The percentage content is 1%) catalyst is added in the reactor, heating, stirring, heating up to 70 ℃~80 ℃, dropwise adding 117.7 grams of hydrazine hydrate aqueous solution with a mass percentage concentration of 85%, and the dropping time is strictly controlled within 1-1.5 hours After the dropwise addition is completed, keep the reaction at a temperature of 70°C to 80°C for 4 hours, filter while it is hot, remove the filter residue, keep the mother liquor, and add 474 ml of deionized water dropwise to the mother liquor while stirring, and let it stand for 5 hours , precipitated a white solid product, filtered, washed 2-3 times with deionized water, and dried to obtain 38.1 grams of 2,5-bis(2-trifluoromethyl-4-aminophenoxy)toluene solid (theoretical yield: 41.4 ...

Embodiment 3

[0039]With 47.4 grams (0.10 moles) 2,5-bis(2-trifluoromethyl-4-nitrophenoxy) toluene, 600 milliliters of ethanol solvent, 3.0 grams of palladium / carbon (the mass percent of metal palladium is 10 %) catalyst into the reactor, heating, stirring, heating up to 70 ℃ ~ 80 ℃, dropwise adding 58.9 grams of hydrazine hydrate aqueous solution with a mass percentage concentration of 85%, and the dropping time is strictly controlled at 1-1.5 hours. , keep the reaction at 70°C to 80°C for 2 hours, filter while it is hot, remove the filter residue, keep the mother liquor, add 300ml of deionized water dropwise to the mother liquor while stirring, let it stand for 6 hours, and precipitate a white solid product , filtered, washed 2-3 times with deionized water, and dried to obtain 39.7 grams of 2,5-bis(2-trifluoromethyl-4-aminophenoxy)toluene solid (theoretical yield: 41.4 grams), purity 99.7 %, product yield 96%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com