Process for recovering benzene-containing tail gas from preparation of cis-butenedioic anhydride by benzene oxidation

A technology of benzene tail gas and maleic anhydride, which is applied in the field of adsorption and recovery of benzene in benzene tail gas, can solve problems such as low adsorption efficiency, waste of benzene resources, and increase environmental protection efforts, and improve the ability and purification efficiency, improve economic and social Benefit, low-cost adsorption treatment effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

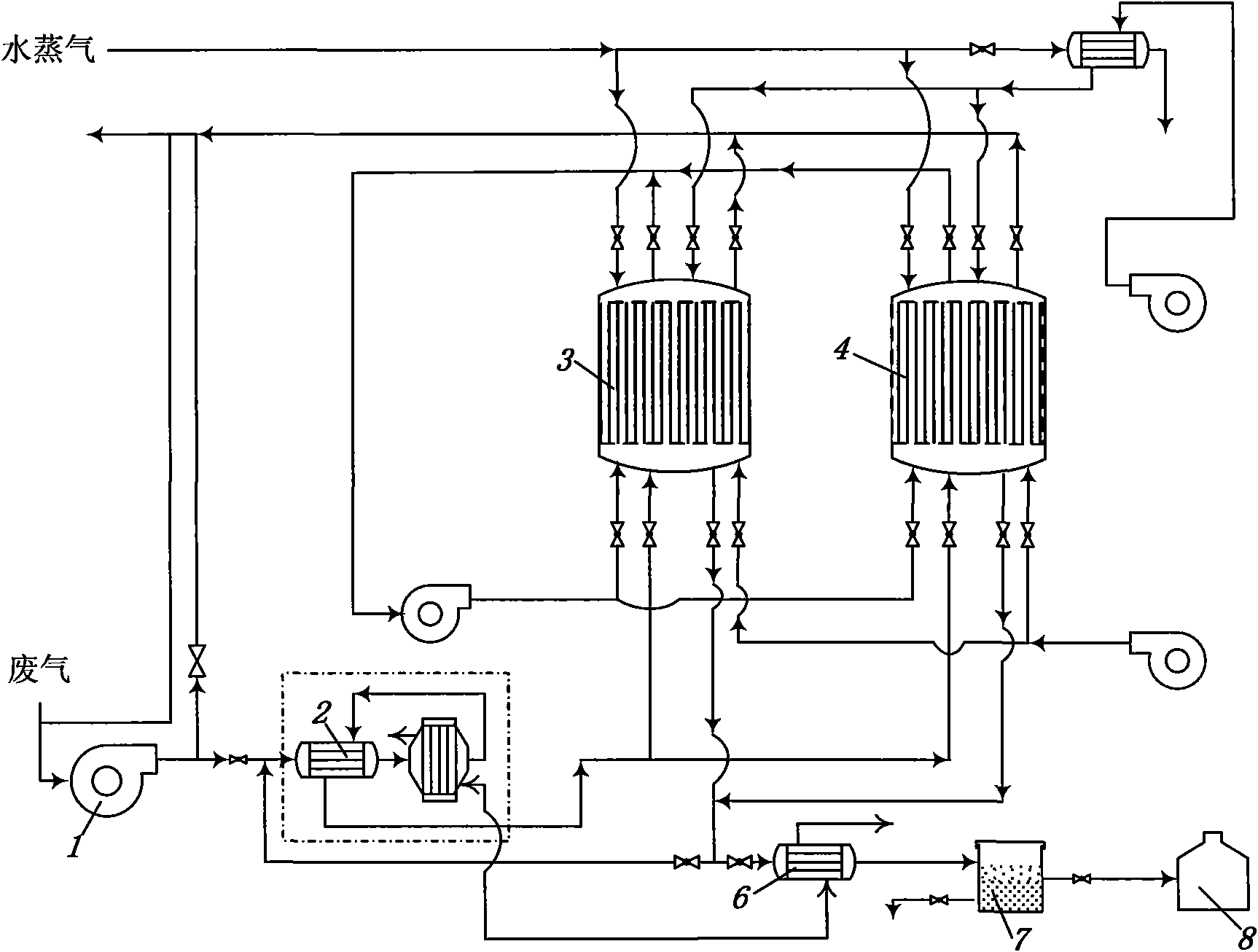

[0024] combine figure 1 , the benzene-containing tail gas comes from the benzene oxidation unit, and the benzene vapor concentration in the tail gas is 1230mg / m 3 , Simultaneously because tail gas has passed through the water washing process of 60 ℃, tail gas is saturated by water vapor, and water vapor accounts for about 19.6% of whole tail gas composition (the water vapor content mentioned below is all by volume), and humidity is 100%. The tail gas is sent into the dehumidifier 2 by the first-stage adsorption fan 1, and the tail gas is first cooled to 24°C in the dehumidifier 2, and the water vapor content is 3%, which is still saturated; At this time, the water vapor content in the tail gas is still 3%, but the relative humidity drops to 40%. Then the dehumidified tail gas enters the primary adsorption tower 3 under the wind pressure of 0.11MPa, and the benzene in it is adsorbed by activated carbon, and the concentration of benzene vapor in the tail gas after the primary a...

Embodiment 2

[0026] The difference between this example and Example 1 is the benzene-containing tail gas saturated with water vapor at 60°C, wherein the concentration of benzene vapor is 1052 mg / m 3 , with a water content of 19.6%, the tail gas is first cooled to 18°C in the dehumidifier 2, the water vapor content is reduced to 2%, and then the temperature is raised to 30°C, and the relative humidity is reduced to 45%. The tail gas after dehumidification enters the first-stage adsorption tower 3 under the wind pressure of 0.13MPa, and the benzene is adsorbed by activated carbon. The concentration of benzene vapor in the tail gas after the first-stage adsorption is 50mg / m 3 , the primary adsorption rate is about 95%; then the primary adsorption tail gas enters the secondary adsorption tower 4 to continue the adsorption, and the concentration of benzene in the discharged tail gas is only 10mg / m 3 , less than 12mg / m 3 The national secondary emission standard, can be discharged directly. W...

Embodiment 3

[0028] The difference between this example and Example 1 is that the tail gas has undergone a water washing process at 80°C, and the benzene concentration in the tail gas is 890 mg / m 3, the water content is as high as 46.8%. The tail gas is first cooled to 25°C in the dehumidifier 2, the water vapor content is reduced to 3%, and then the temperature is raised to 40°C, and the relative humidity is reduced to 40%. The tail gas after dehumidification enters the first-stage adsorption tower 3 under the wind pressure of 0.12MPa, and the benzene is adsorbed by activated carbon. The concentration of benzene vapor in the tail gas after the first-stage adsorption is 48mg / m 3 , the primary adsorption rate is about 95%; then the primary adsorption tail gas enters the secondary adsorption tower 4 to continue the adsorption, and the concentration of benzene in the discharged tail gas is only 9mg / m 3 , less than 12mg / m 3 The national secondary emission standard, can be discharged directly....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com