Gradient structure carbon nano-tube enhanced Ti(C, N)-based metal ceramic and preparation method thereof

A carbon nanotube and gradient structure technology, which is applied in metal material coating process, coating, solid-state diffusion coating, etc., can solve the problems of thin surface functional gradient layer, easy peeling of surface hardened layer, and high cost of coating preparation. To achieve the effect of increasing the amount of feed, superior comprehensive mechanical properties, and excellent toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

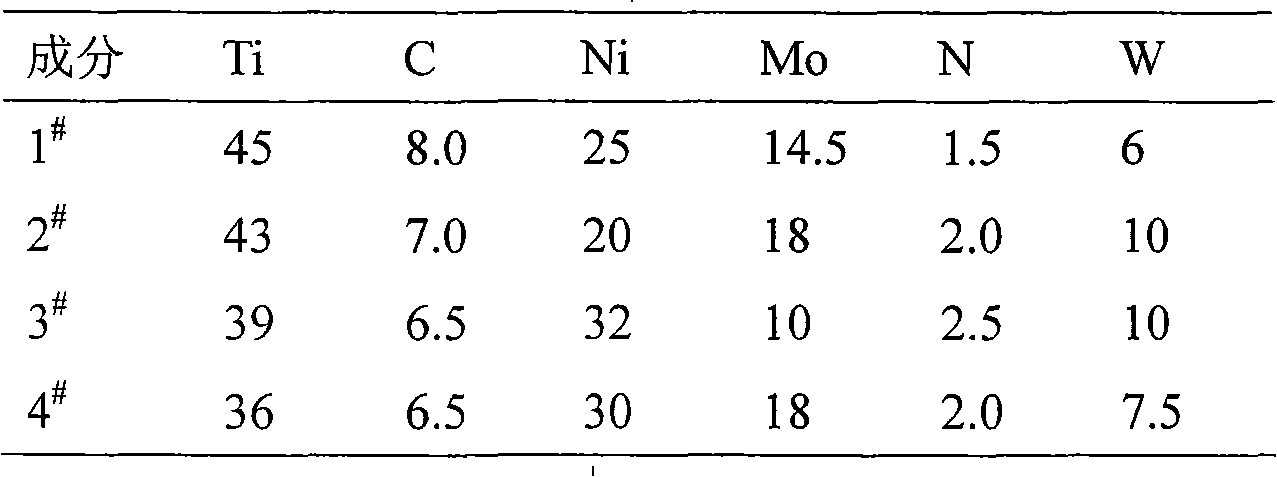

Embodiment 1

[0031] When preparing the mixture, 0.5 part of the carbon is introduced by carbon nanotubes;

[0032] The mixing process is carried out in a planetary ball mill, the speed of the ball mill is 160rpm, and the time is 24h;

[0033] The addition amount of molding agent polyvinyl alcohol is 3mass%, and the pressure used for compression molding is 250MPa;

[0034] The degreasing process is carried out under the condition that the vacuum degree is higher than 10Pa, and the heating rate between 200-400°C is 0.3°C / min;

[0035] The vacuum degree of vacuum sintering is higher than 5.0×10 -2 Pa, the sintering temperature is 1410°C, and the holding time is 60min.

[0036] The purity of argon gas used in double-layer glow plasma carburizing treatment is ≥99.0%, the pressure of argon gas filled in the furnace cavity is 20Pa, the treatment temperature is 1100°C, and the treatment time is 180min.

[0037] Under the above-mentioned preparation process conditions, the properties of cermets ...

Embodiment 2

[0041] When preparing the mixture, 0.75 parts of carbon are introduced by carbon nanotubes;

[0042] The mixing process is carried out in a planetary ball mill, the speed of the ball mill is 180rpm, and the time is 16h;

[0043]The addition amount of molding agent polyvinyl alcohol is 5mass%, and the pressure used for compression molding is 300MPa;

[0044] The degreasing process is carried out under the condition that the vacuum degree is higher than 10Pa, and the heating rate between 200-400°C is 0.4°C / min;

[0045] The vacuum degree of vacuum sintering is higher than 5.0×10 -2 pa, the sintering temperature is 1430°C, and the holding time is 80min.

[0046] The purity of argon gas used in double-layer glow plasma carburizing treatment is ≥99.0%, the pressure of argon gas filled in the furnace cavity is 30Pa, the treatment temperature is 1100°C, and the treatment time is 90min.

[0047] Under the above-mentioned preparation process conditions, the properties of cermets wit...

Embodiment 3

[0051] When preparing the mixture, 1.0 part of the carbon is introduced by carbon nanotubes;

[0052] In the mixing process, the ball mill rotating speed is 220rpm, and the time is 12h;

[0053] The addition amount of molding agent polyvinyl alcohol is 5mass%, and the pressure used for compression molding is 320MPa;

[0054] The degreasing process is carried out under the condition that the vacuum degree is higher than 10Pa, and the heating rate between 200-400°C is 0.4°C / min;

[0055] The vacuum degree of vacuum sintering is higher than 5.0×10 -2 pa, the sintering temperature is 1450°C, and the holding time is 60min;

[0056] The purity of argon gas used in double-layer glow plasma carburizing treatment is ≥99.0%, the pressure of argon gas filled in the furnace cavity is 40Pa, the treatment temperature is 1200°C, and the treatment time is 90min.

[0057] Under the above-mentioned preparation process conditions, the properties of cermets with different composition ratios ar...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap