Novel polyolefin resin composition and molded resin obtained therefrom

A technology of olefin-based resin and composition, applied in the field of new polyolefin-based resin composition and its preparation, can solve the problems of low transparency, crystallinity and rigidity, achieve excellent transferability, excellent crystallinity, and improve operation efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific example

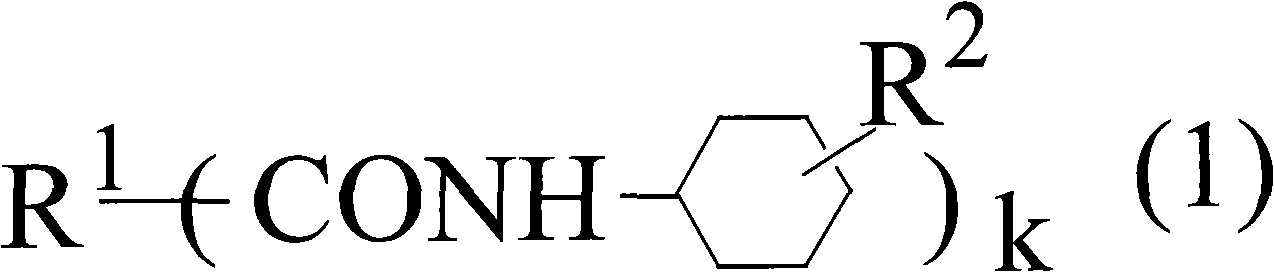

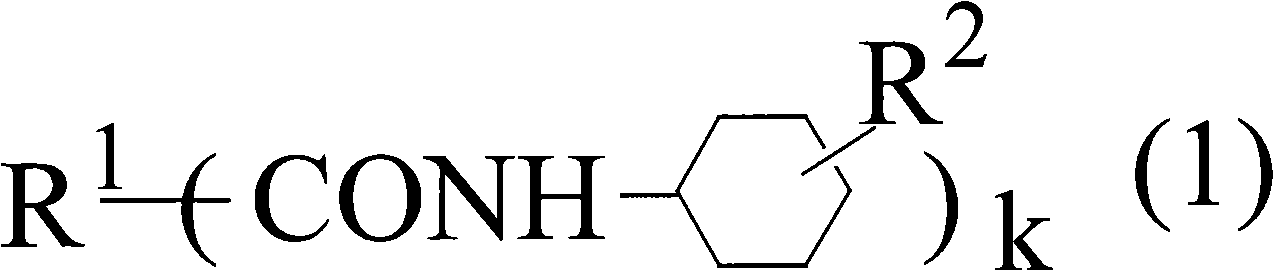

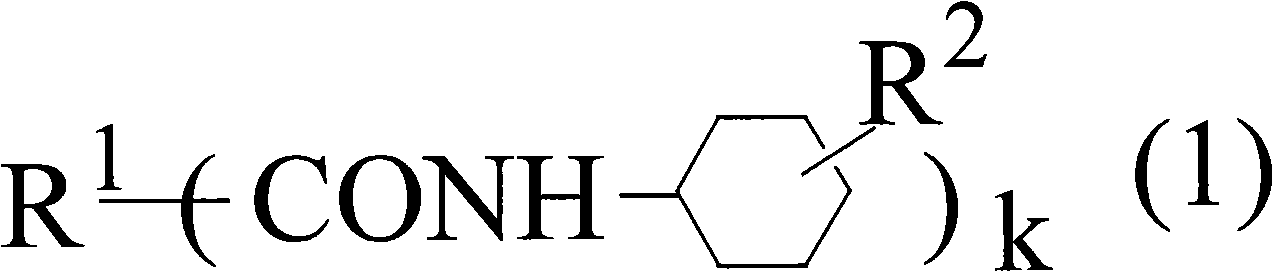

[0267] When the effect of improving transparency is important, the amido compound represented by the general formula (1) is preferred, wherein R 1 A residue obtained by removing all carboxyl groups from 1,2,3-propanetricarboxylic acid or 1,3,5-benzenetricarboxylic acid. The specific examples are as follows:

[0268] 1,2,3-Propanetricarboxylic acid tricyclohexylamide;

[0269] 1,2,3-propanetricarboxylic acid tris(2-methylcyclohexylamide);

[0270] 1,2,3-propanetricarboxylic acid tris(3-methylcyclohexylamide);

[0271] 1,2,3-propanetricarboxylic acid tris(4-methylcyclohexylamide);

[0272] 1,3,5-Benzenetricarboxylic acid tricyclohexylamide;

[0273] 1,3,5-Benzenetricarboxylic acid tris(2-methylcyclohexylamide), etc.

[0274] The above amide-based compounds may be used alone or in appropriate combination of two or more.

[0275] The crystal form of the amido compound of the present invention is not limited as long as the effect of the present invention can be achieved; any ...

Embodiment

[0335] The present invention is described in detail with reference to the following Examples and Comparative Examples, but the Examples and Comparative Examples are not intended to limit the present invention.

[0336] The pH value and particle size of the inorganic compound used according to the present invention are measured by the methods described in the following items (1) and (2), respectively. The crystallinity, rigidity, heat resistance and transparency of the polyolefin-based resin molded body were evaluated by the methods described in the following items (3) to (6), respectively.

[0337] (1) pH value

[0338] 50 ml of a 50 v / v % ethanol aqueous solution was put into a 100 ml Erlenmeyer flask, and then 1 g of an inorganic compound was added thereto. The mixture was stirred with a magnetic stirrer in a constant temperature bath at 25° C. to disperse the inorganic compound. At exactly 10 minutes after the addition of the inorganic compound, the pH of the stirred disp...

preparation example 1

[0352] 9.7 g (0.055 mol) of 1,2,3-propanetricarboxylic acid and 100 g of N-methyl-2-pyrrolidone were put into a 500 ml four-necked flask equipped with a stirrer, thermometer, cooling tube and gas inlet. The mixture was stirred at room temperature under a nitrogen atmosphere until the 1,2,3-propanetricarboxylic acid was completely dissolved.

[0353] Next, 20.5 g (0.1815 mol) of 2-methylcyclohexylamine (trans isomer: cis isomer = 74.3: 25.7; GLC area %), 56.3 g (0.1815 mol) of triphenyl phosphite, 14.4 g (0.1815 mol) of pyridine, and 50 g of N-methyl-2-pyrrolidone, and the mixture was reacted at 100° C. for 4 hours while stirring in a nitrogen atmosphere. After cooling, the reaction solution was slowly poured into a mixture of 500 ml of isopropanol and 500 ml of water, and the resulting mixture was stirred at about 40° C. for 1 hour. Then, the white precipitate thus formed was filtered off. The resulting white solid was washed twice with 500 ml of isopropanol at about 40°C, a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com