Corrosive liquid used for monocrystal line silicon matte preparation and monocrystal line silicon matte preparation method

A technique for etching liquid and monocrystalline silicon wafers, which is applied in the field of etching liquid, and can solve the problems of high cost, complicated preparation method, and unresolved instability of etching liquid.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] Example 1: Prepare a 1% NaOH aqueous solution, add 1 mg / L sodium lauryl sulfate and 6% sodium silicate, and the corrosion solution is prepared. After the etching solution was mixed uniformly by bubbling at a constant temperature of 95° C., the monocrystalline silicon wafer was etched in the etching solution for 30 minutes to obtain pyramids with an average size of about 5 μm.

Embodiment 2

[0019] Example 2: Prepare 5% KOH aqueous solution, add 100 mg / L sodium lauryl sulfate and 0% sodium silicate, and the corrosion solution is prepared. The etching solution was kept at a constant temperature of 90° C., and mixed evenly by bubbling, and the monocrystalline silicon wafer was etched in the etching solution for 25 minutes to obtain pyramids with an average size of about 6 μm.

Embodiment 3

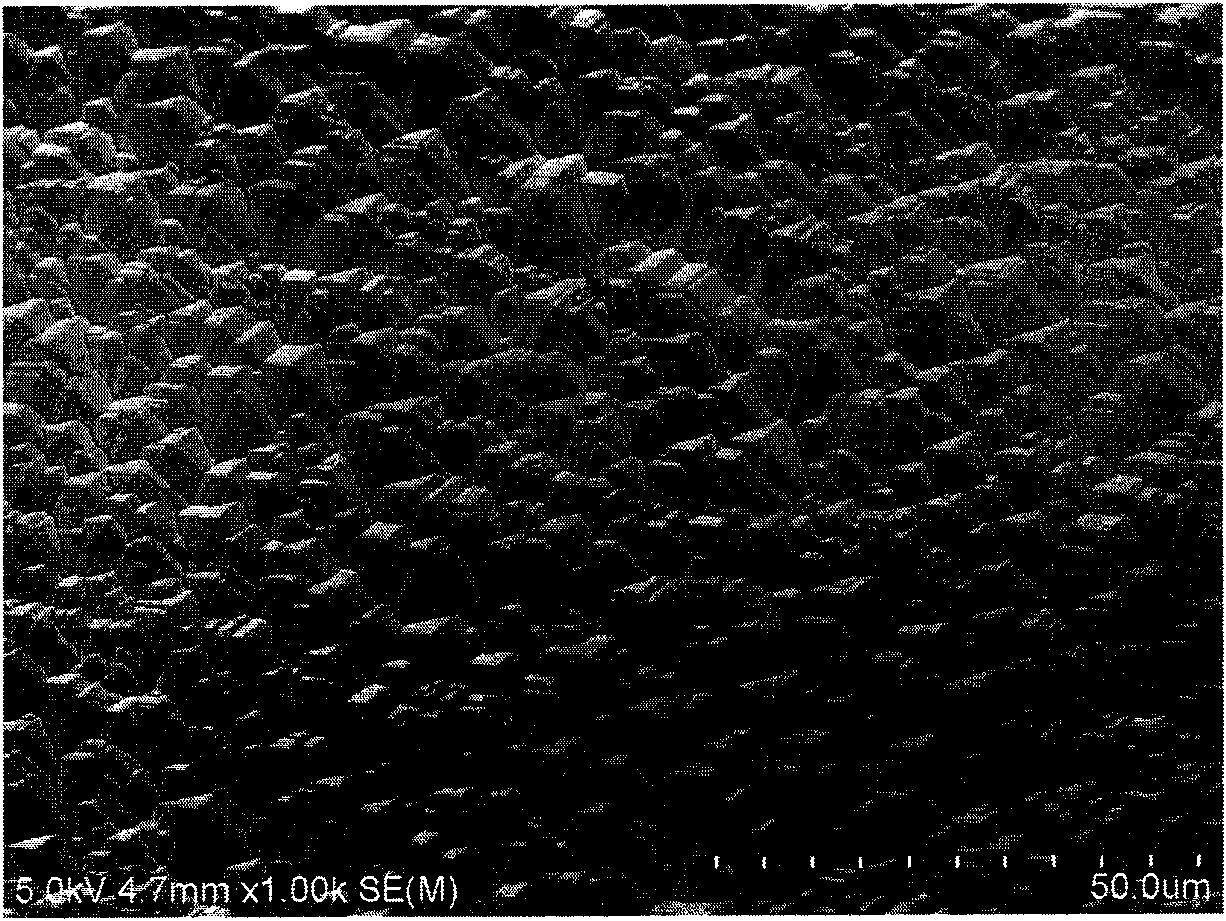

[0020] Example 3: Prepare 2% NaOH aqueous solution, add 10 mg / L sodium lauryl sulfate and 0.5% sodium silicate, and the corrosion solution is prepared. The etching solution was kept at a constant temperature of 85°C, and after bubbling and mixing evenly, the monocrystalline silicon wafer was etched in the etching solution for 15 minutes to obtain pyramids with an average size of about 5 μm, as shown in figure 2 As shown, the pyramids are all over the surface of the silicon wafer and are uniform in size.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average size | aaaaa | aaaaa |

| Average size | aaaaa | aaaaa |

| Average size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com