Catalyst for preparing chloromethane and ammonia gas and preparation method thereof

A catalyst, methyl chloride technology, applied in catalyst activation/preparation, chemical instruments and methods, physical/chemical process catalysts, etc., can solve problems such as less research, and achieve the effect of simple process, low cost and high catalytic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Use the supersaturated water absorption method to measure the unit gram of γ-Al 2 o 3 The saturated water absorption capacity of the carrier is 0.6ml. Pour 12ml of a solution containing 1.2g of titanium dioxide into 20g of γ-Al 2 o 3 Carrier, stirred, impregnated for 24 hours, dried at 120°C for 4 hours, and calcined at 550°C for 6 hours to obtain TiO 2 with γ-Al 2 o 3 N-γ-Al with a carrier mass ratio of 0.06:1 2 o 3 , N is a modifier.

[0021] N-γ-Al 2 o 3 As a carrier, use the supersaturated water absorption method to measure the unit gram N-γ-Al 2 o 3 The saturated water absorption is 0.5ml. Pour 10ml of nickel nitrate solution containing 0.8g of nickel into 20g of N-γ-Al 2 o 3 in, stirred, impregnated for 24 hours, dried at 120°C for 4 hours, and calcined at 550°C for 6 hours to obtain Ni and N-γ-Al in the active component 2 o 3 The mass ratio of the catalyst is 0.04:1, the catalyst is expressed as Cat, and the catalyst in Example 1 is Cat1.

[0022...

Embodiment 32

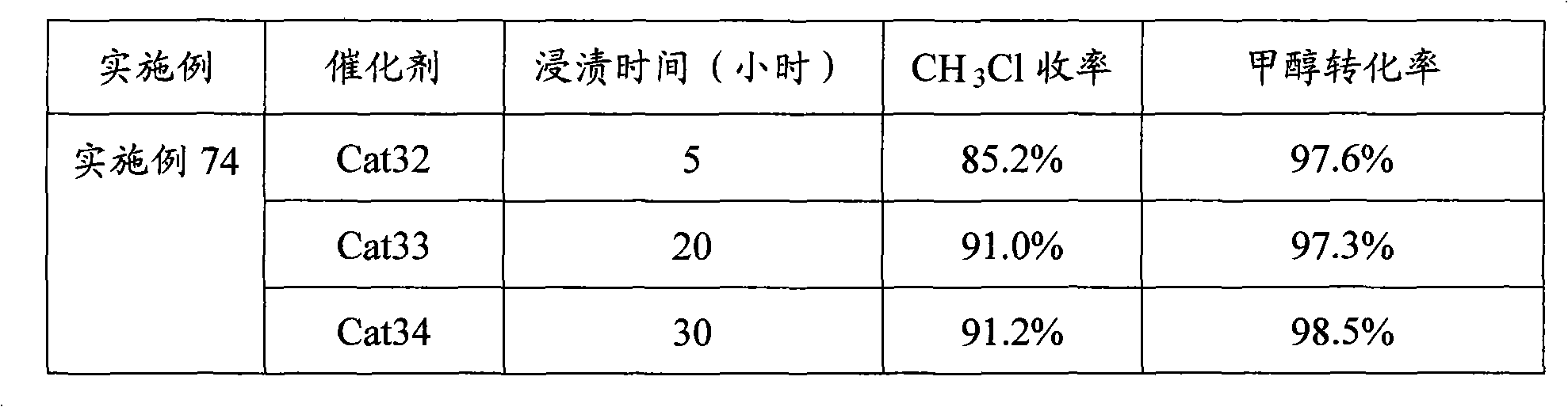

[0033] The influence of catalyst impregnation time, the catalyst Cat14 is used as the probe catalyst. The difference from Example 14 is that the immersion time during the preparation of the catalyst is 5 hours to 30 hours, and the catalyst is Cat32-Cat34.

[0034] Cat32~Cat34 were tested for activity according to the catalyst activity evaluation method, and the results are shown in Table 3.

[0035] The catalytic activity of the prepared catalyst of table 3 embodiment 32

[0036]

[0037] Table 3 has listed the catalyst activity test result prepared by embodiment 32, and wherein soaking time exceeds 20 hours, and the activity of catalyst is basically stable, shows higher activity, CH 3 The yield of Cl reaches more than 90%, and the conversion rate of methanol is greater than 97%.

Embodiment 33

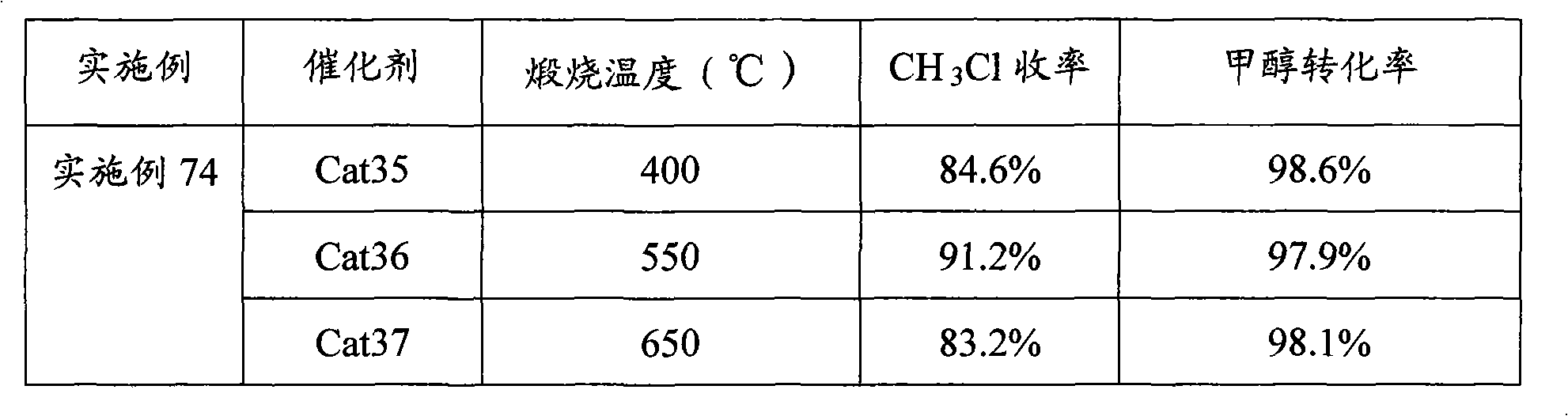

[0039] Influence of catalyst calcination temperature, catalyst Cat14 is used as probe catalyst. The difference from Example 14 is that the calcination temperature in the preparation process of the catalyst is 400°C-650°C, and the catalyst is recorded as Cat35-Cat37.

[0040] Cat35-Cat37 were tested for activity according to the catalyst activity evaluation method, and the reaction results are shown in Table 4.

[0041] The catalytic activity of the prepared catalyst of table 4 embodiment 33

[0042]

[0043] Table 4 lists the catalysts prepared in Example 33 for activity test comparison, wherein when the calcination temperature was 550 ° C, the catalyst showed higher activity, CH 3 The yield of Cl reaches more than 90%, and the conversion rate of methanol is greater than 97%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Saturated water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com