Semiconductor film of organic film solar battery as well as forming method and manufacturing method thereof

A technology for solar cells and organic thin films, which is applied in the manufacture of semiconductor/solid-state devices, semiconductor devices, and electric solid-state devices, etc., can solve the problems of reduced service life, unstable morphology, and inability to effectively control the morphology, and can improve the current , the effect of increasing the junction area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

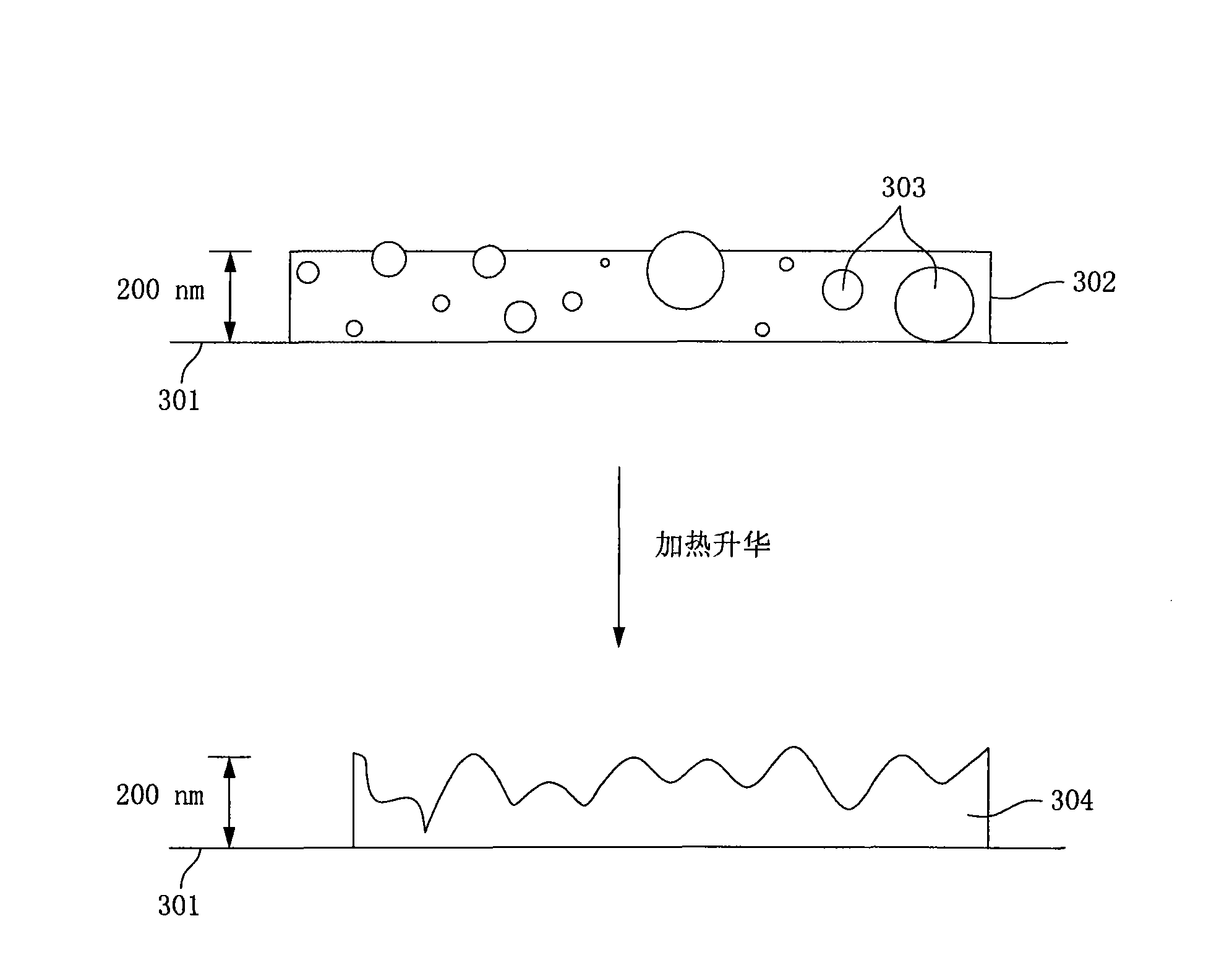

[0045] Generally speaking, the present invention is by at least comprising: adding solid substance in the coating liquid of semiconducting material; Coating coating liquid on an interface; type material to obtain a semiconductor film with a rough surface.

[0046]So far, there are two main methods to create microporous pores in polymer films so as to control surface roughness. One is to use the principle of phase separation of two incompatible polymers, and decompose them by heating after phase separation. , radiation decomposition or hydrolysis to remove one of the polymers to form a film with microporosity. Another method is to use block copolymers (Block copolymer) to form different morphologies (morphology). One of the polymers is removed by decomposition, radiolysis or hydrolysis to form a thin film with microporosity. The above methods all involve the problems of molecular chain scission and complete removal of impurities, which are not suitable for the application of s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com