Method for enhancing preservative effect of lightning protection ground material

An anti-corrosion effect, lightning protection and grounding technology, applied in the direction of connection contact materials, anti-corrosion coatings, metal material coating technology, etc., can solve the problems of corrosion of the main material metal, unsuitable for corrosion environment, unsuitability, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

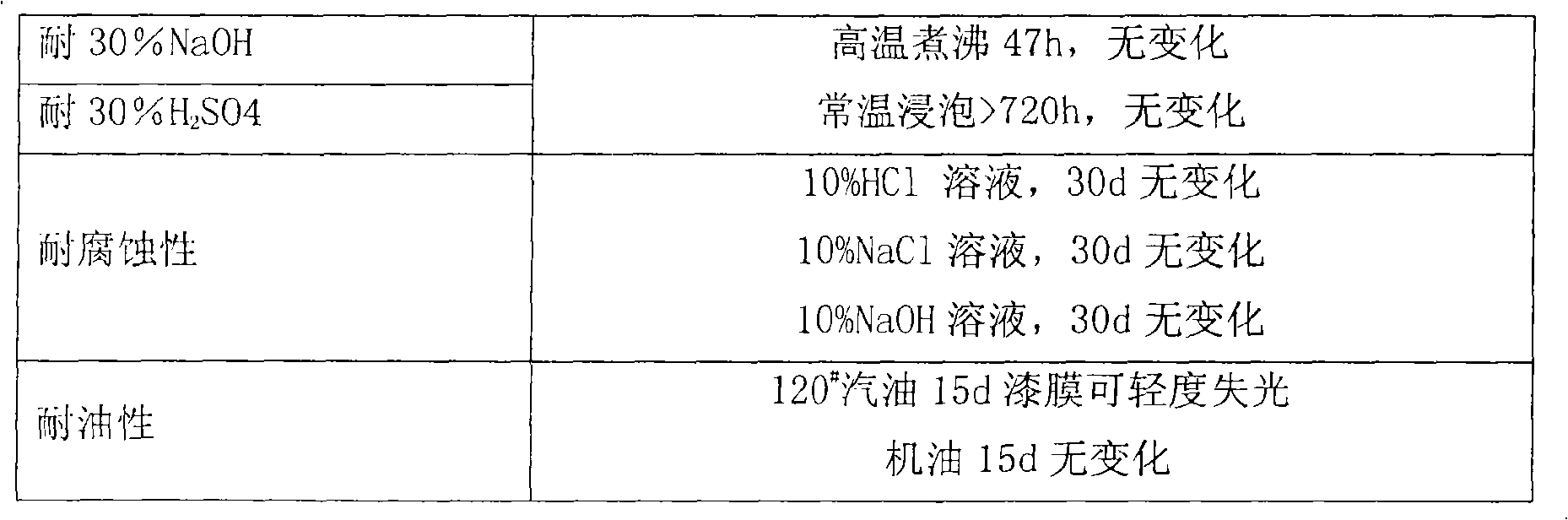

Examples

Embodiment 1

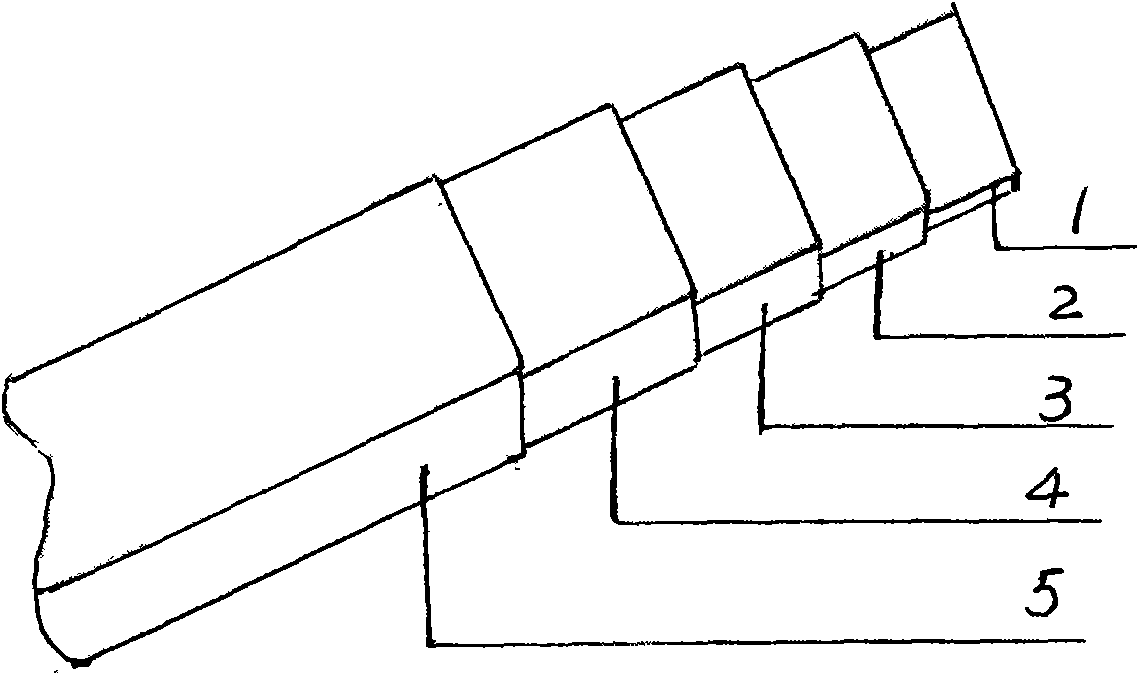

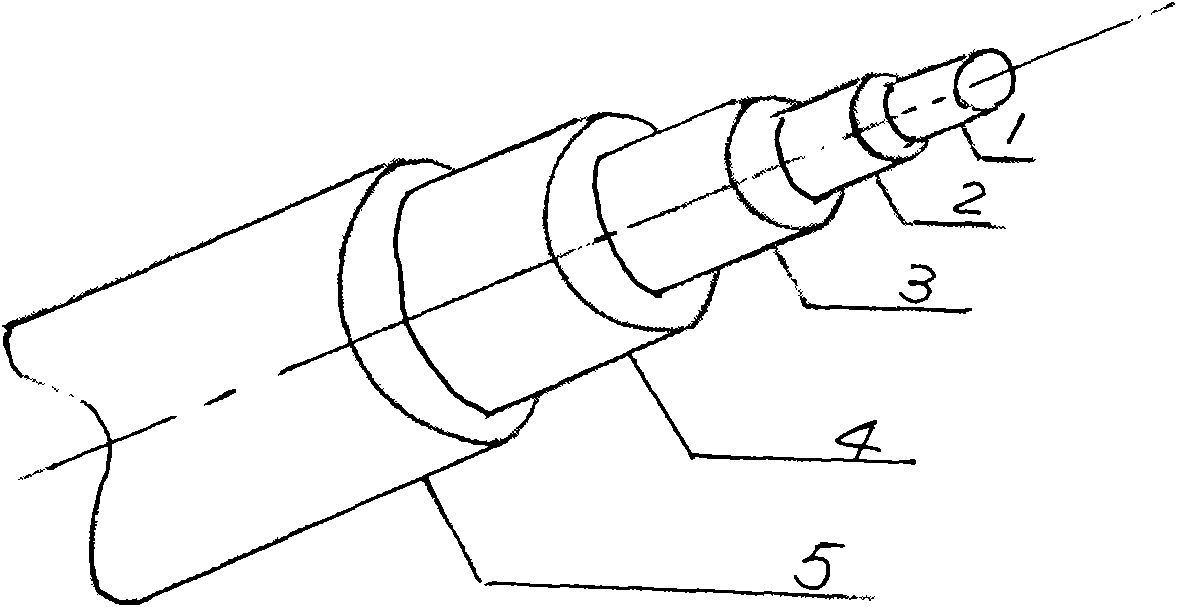

[0049] Methods of enhancing the anti-corrosion effect of lightning protection and grounding materials:

[0050] 1. Pre-treat the surface of the metal matrix grounding material used for grounding to form a conversion film layer, and form a dense conversion film layer 2 at room temperature, with a thickness of 40-80 μm, which is used to strengthen the subsequent anti-corrosion conductive layer. Adhesion transition layer.

[0051] The raw material of pretreatment liquid is all commercially available, takes by weight respectively: zinc phosphate 0.1g (0.1%); Titanium nitrate 6g (6%); Conductive zinc powder 0.01g (0.01%), ammonium molybdate 3g ( 3%), iron filings 0.2g (0.2%); water 90.69g (90.69%).

[0052] Mix the above-mentioned raw materials according to the weight ratio evenly, control the pH of the treatment solution to 1.0 to 5.2, and the density to 1 to 1.08 to form a pretreatment solution, apply it on the surface of the metal base material used for grounding, and dry at ro...

Embodiment 2

[0070] Methods of enhancing the anti-corrosion effect of lightning protection and grounding materials:

[0071] 1. Pre-treat the surface of the metal matrix grounding material used for grounding to form a conversion film layer, and form a dense and conductive conversion film layer 2 at room temperature, with a thickness of 40-80 μm. Transition layer for the adhesion of subsequent anti-corrosion conductive layers.

[0072] The raw materials of pretreatment liquid are all commercially available, and take by weight respectively: zinc phosphate 5g (5%); Titanium nitrate 0.2g (0.2%); Conductive zinc powder 5g (5%), ammonium molybdate 0.1g ( 0.1%), iron filings 0.1g (0.1%); water 89.6g (89.6%).

[0073] Mix evenly according to the weight ratio, control the pH=1.0-5.2, and the density is 1-1.08 to form a pretreatment liquid, apply it on the surface of the metal base material used as grounding, and dry it at room temperature for 0.5 hours to form a layer of compactness. Conductive c...

Embodiment 3

[0090] Methods of enhancing the anti-corrosion effect of lightning protection and grounding materials:

[0091] 1. Pre-treat the surface of the metal matrix grounding material used for grounding to form a conversion film layer, and form a dense and conductive conversion film layer 2 at room temperature, with a thickness of 40-80 μm. Transition layer for the adhesion of subsequent anti-corrosion conductive layers.

[0092] The raw materials of pretreatment liquid are all commercially available, and take by weight respectively: zinc phosphate 3g (3%); Titanium nitrate 2.8g (2.8%); Conductive zinc powder 2.5g (2.5%), ammonium molybdate 1.5g (1.5%), iron filings 0.1g (0.1%); water 90.1g (90.1%).

[0093] Mix evenly according to the above weight ratio, control the pH=1.0~5.2, and the density is 1~1.08 to form a pretreatment liquid, apply it on the surface of the metal base material used as grounding, and dry it at room temperature for 0.5 hours to form a dense layer The conversio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Volume resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com