Method for preparing III-V compound semiconductor nanotube structure material by GSMBE

A technology of structural materials and semiconductors, applied in the field of preparation of III-V compound semiconductor materials, achieving the effects of environmental friendliness, multiple epitaxy methods, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

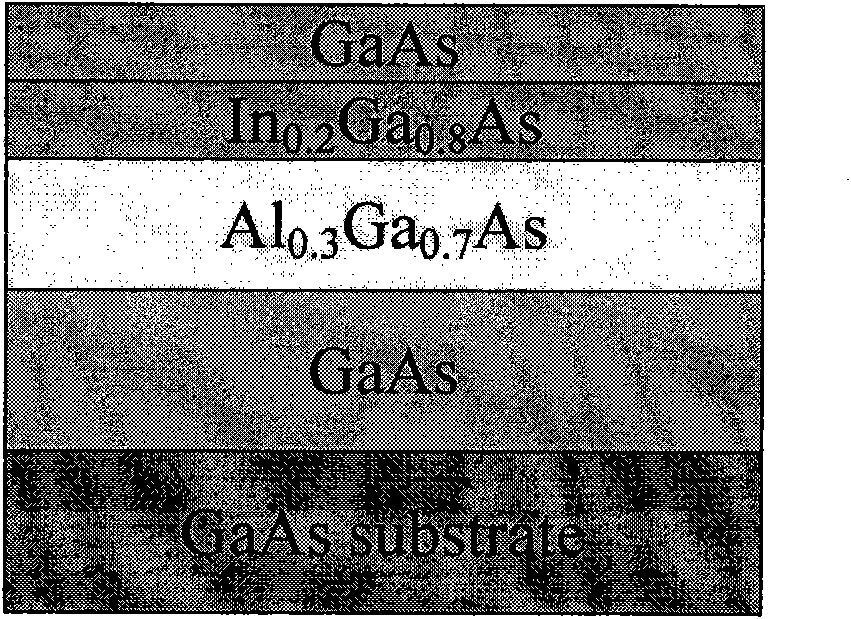

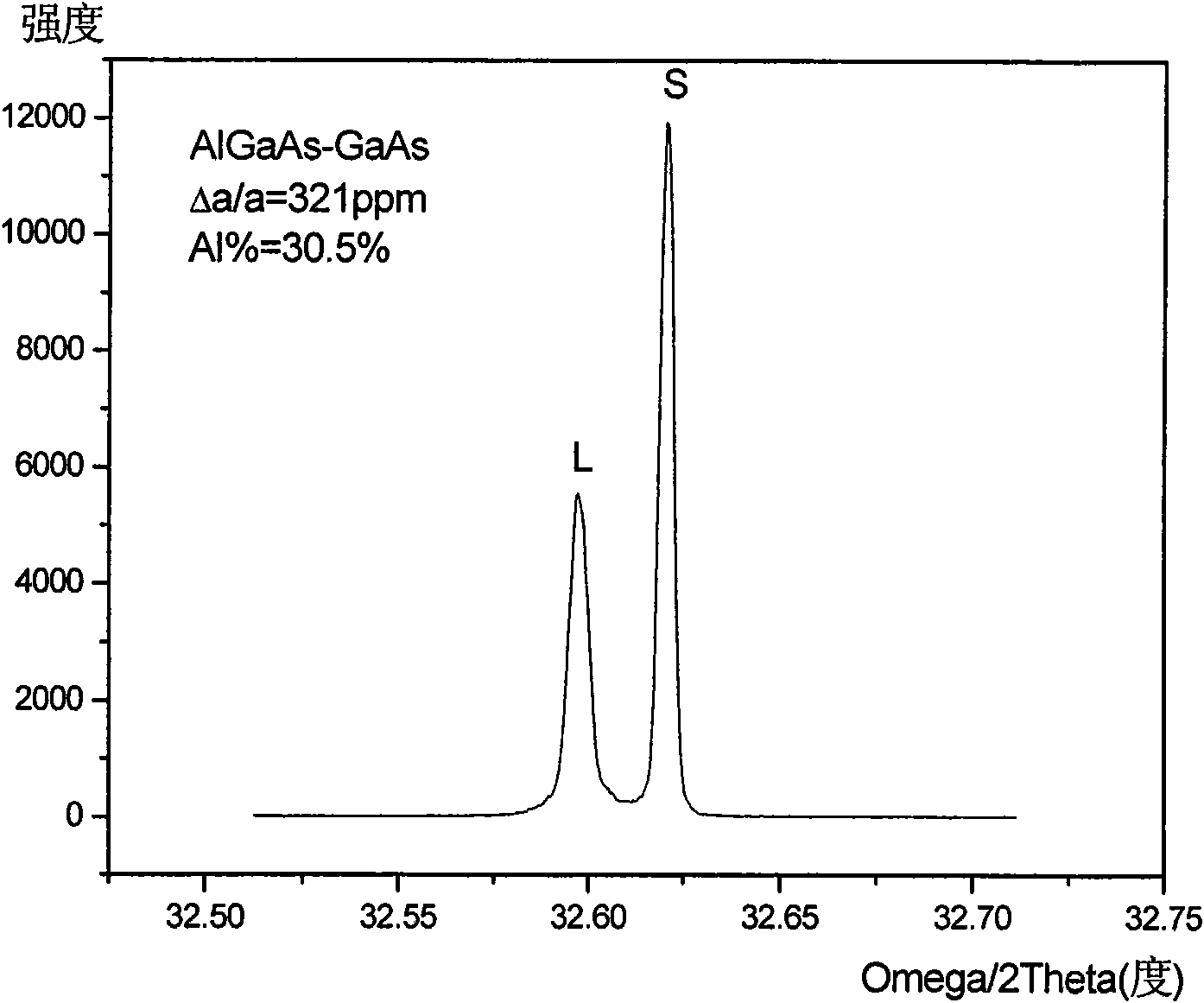

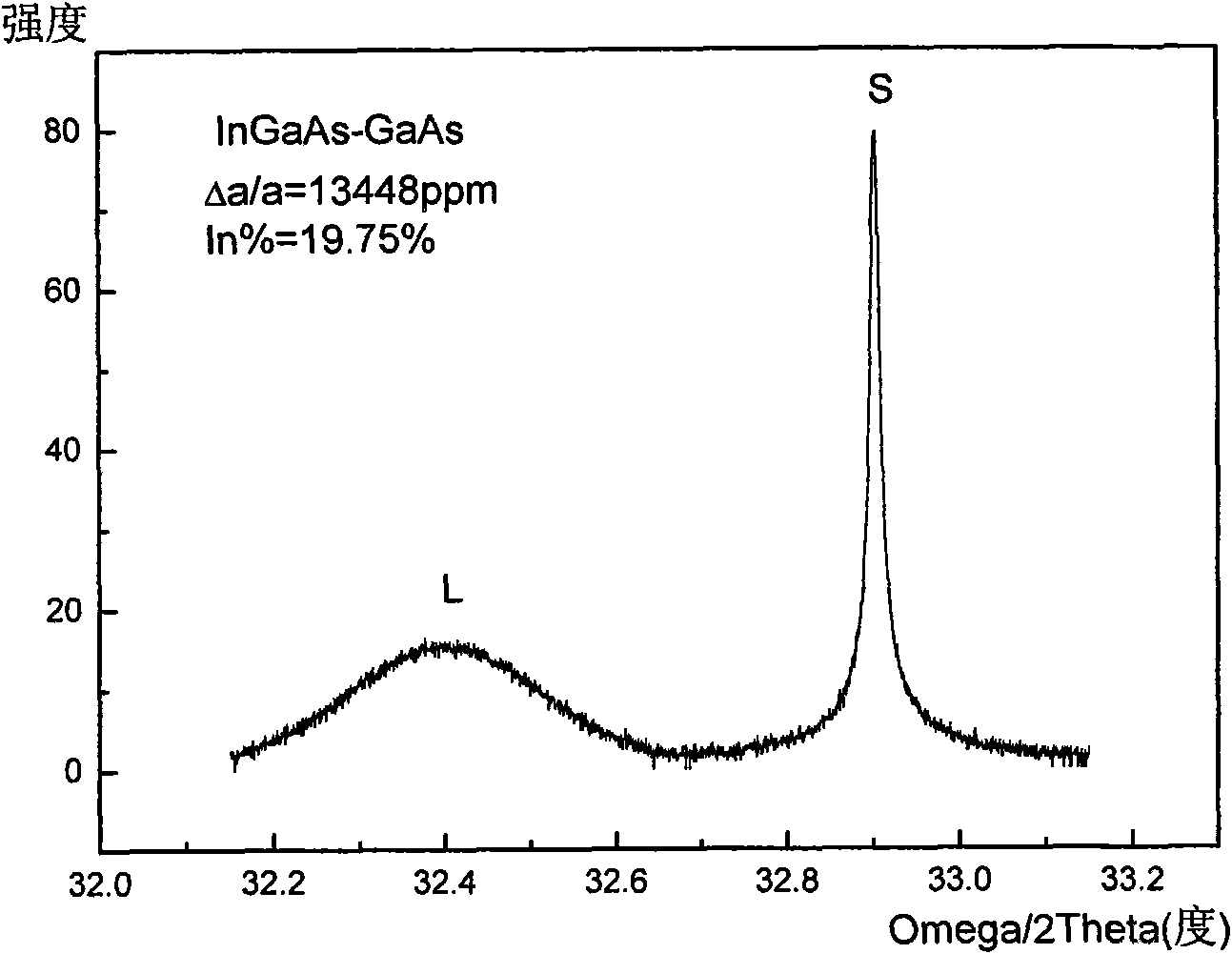

[0030] The material was grown on the semi-insulating single-throw GaAs(100) substrate by gas source molecular beam epitaxy, and the substrate temperature was 580°C. First, a 300nm GaAs buffer layer is epitaxially grown on the GaAs substrate, and a 1.6μm AlGaAs material is grown as a corrosion sacrificial layer. A 6nm InGaAs strained layer is grown on the corrosion sacrificial layer, and a 6nm GaAs inner tube wall is grown on the strained InGaAs material layer. material growth. pass figure 2 and image 3 According to the x-ray test analysis, the AlGaAs corrosion layer material and the InGaAs strain layer material composition meet the design requirements, and the material quality is very good.

[0031] The specific process is as follows:

[0032] (1) Send the GaAs(100) substrate into the pretreatment chamber of the gas source molecular beam epitaxy system GSMBE, and degas at 400-450°C for 25-35 minutes;

[0033](2) Transfer the above substrate to the growth chamber of GSMBE...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com