Composite membrane taking carboxylate ion as fixed carrier and preparation method thereof

A fixed carrier and composite membrane technology, applied in chemical instruments and methods, membrane technology, semi-permeable membrane separation, etc., can solve the problems of affecting membrane separation performance, affecting membrane life, and easy oxidation of amine groups, so as to achieve the goal of not being easily oxidized , good separation performance, good stability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

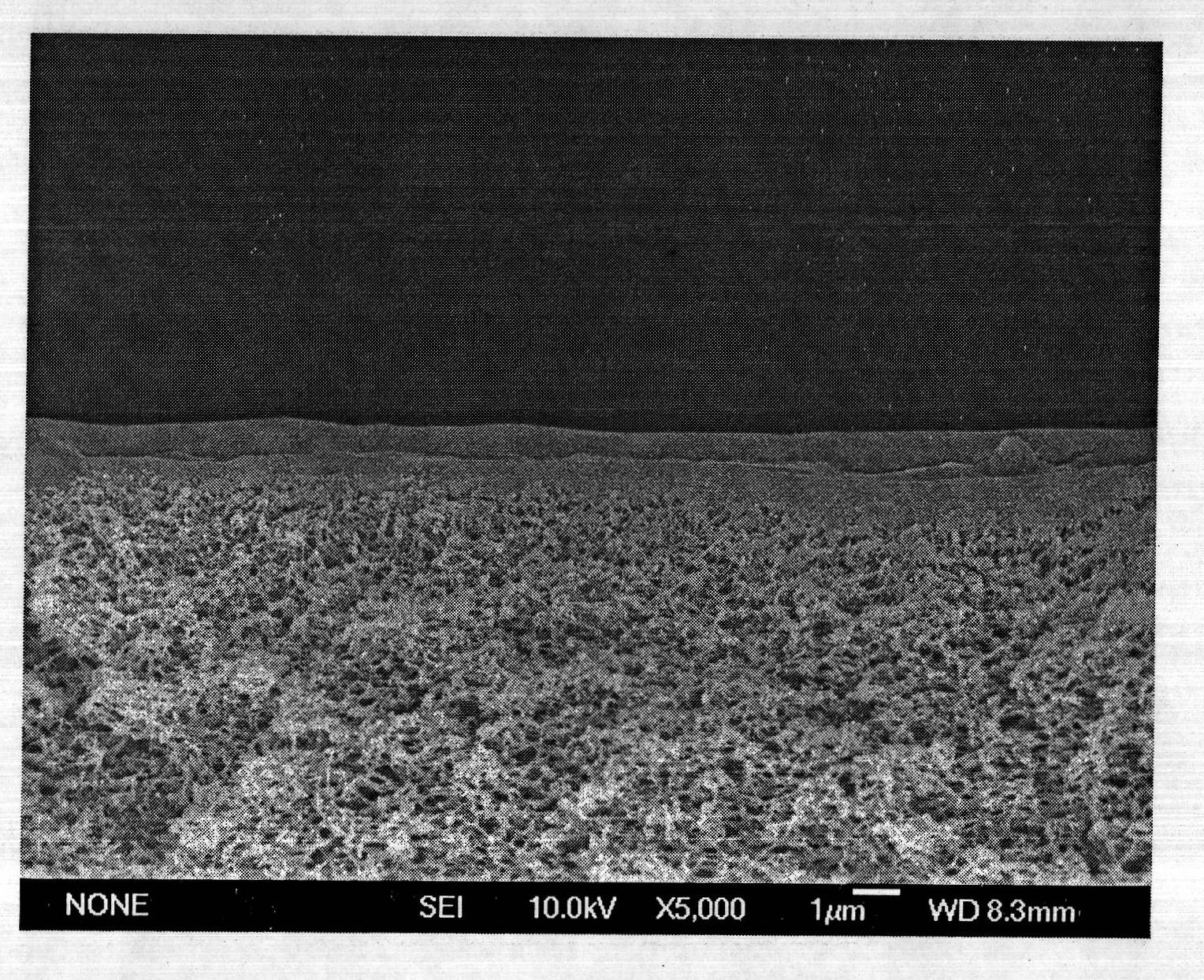

Image

Examples

Embodiment 1

[0017] Weigh 50g of sodium acrylate solution with a mass fraction of 10% and place it in a 250ml three-necked flask, add 50g of water, and pass N 2 After purging for 0.5h, react in a water bath at 45°C for 7.5h. Slowly pour the polymer solution into a beaker filled with ethanol, stir well to make it precipitate, take out the precipitate, and dry it in a vacuum oven at 40°C to obtain sodium polyacrylate. Dissolve sodium polyacrylate in a plastic flask to prepare an aqueous solution with a mass concentration of 0.375%, pour it into a plastic reagent bottle and let it stand for 24 hours to be used as a casting solution. A polysulfone flat membrane (nominal molecular weight cut-off of 30,000) with a size of 22cm×13cm is immersed in an aqueous sodium carbonate solution with a mass concentration of 1%, soaked at room temperature for 24h, rinsed and immersed in an aqueous ethanol solution with a volume concentration of 20%, Soak at room temperature for 24 hours, dry for later use. ...

Embodiment 2

[0019]Weigh 3.2g of acrylamide, 10g of 10% sodium acrylate solution, and 68.8g of deionized water, mix them and place them in a 250ml three-necked flask. Install the stirrer and react in a 45°C water bath for 7.5 hours. Slowly pour the polymer solution into a beaker filled with ethanol, stir well to make it precipitate, take out the precipitate and place it in a vacuum oven at 40°C to dry to obtain the copolymer P(SA-co-AM) of sodium acrylate-acrylamide. Put the copolymer into a plastic flask to dissolve, prepare an aqueous solution with a mass concentration of 0.375%, pour it into a plastic reagent bottle and let it stand for 24 hours to be used as a casting solution. Treat the polysulfone flat membrane according to the size of the base membrane and the pretreatment method in Example 1, get 4g of the above-mentioned casting solution and coat it on the treated polysulfone flat membrane, and dry it at a temperature of 30°C and a relative humidity of 40% to obtain separation Fa...

Embodiment 3

[0021] Weigh 2.8g of acrylamide, 24g of 10% sodium acrylate solution, and 77.2g of deionized water, mix them and place them in a 250ml three-necked flask. Install the stirrer and react in a 45°C water bath for 7.5 hours. Slowly pour the polymer solution into a beaker filled with ethanol, stir well to make it precipitate, take out the precipitate and place it in a vacuum oven at 40°C to dry to obtain the copolymer P(SA-co-AM) of sodium acrylate-acrylamide. The copolymer was dissolved in a plastic flask, prepared into an aqueous solution with a mass concentration of 1%, poured into a plastic reagent bottle and left to stand for 24 hours to be used as a casting solution. Treat the polysulfone flat membrane according to the size of the base membrane and the pretreatment method in Example 1, get 4g of the above-mentioned casting solution and coat it on the treated polysulfone flat membrane, and dry it at a temperature of 30°C and a relative humidity of 40% to obtain separation Fac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

| separation factor | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com