High-growth-rate Dunaliella tertiolecta obtained through ethylmethane sulfonate mutation breeding

A technology of ethyl methyl sulfonate and growth rate, applied in the field of microbial engineering, can solve the problems of less breeding research, low probability of mutant strains, time-consuming and labor-intensive

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0058] Example 1 Screening of Dunaliella mutagenic strains with high growth rate

[0059] The wild strain of Dunaliella tertiolecta UTEX LB 999 (purchased from the University of Texas) was used as the starting algal strain, added ethyl methanesulfonate (EMS) (1% final concentration, volume ratio) for mutagenesis, and then isolated and subcultured for preservation. After activation of the above-mentioned mutagenic algae strains, they were screened in multiple steps under normal culture conditions (25°C, 4000lux, 12h L / 12h D) in an artificial climate box, and the OD 750 The value is to measure the mutagenized algae strains with high growth rate step by step.

[0060] The composition and content of the culture medium are shown in Table 1.

[0061] The composition and content of table 1EM medium

[0062] #

Element

quantity

Stock solution concentration

Final concentration at the time of use

1

3L

2 ...

Embodiment 2

[0077] Example 2 The identification characteristics of the mutant algae strain ENN0001-7 obtained by screening

[0078] The algal cells of the mutant algal strain ENN0001-7 were pear-shaped or oval, about 6-10 μM in length, with 2 equal-length flagella, no cellulosic cell wall, and only an outer membrane composed of glycoprotein and neuraminic acid. It can grow in EM, F / 2 and other media. The algae are evenly dispersed in the liquid medium and can swim. It grows well on EM solid medium, and obvious single algae colonies can be formed in 5-7 days. The algae fall into a regular circle, and the algae are green.

Embodiment 3

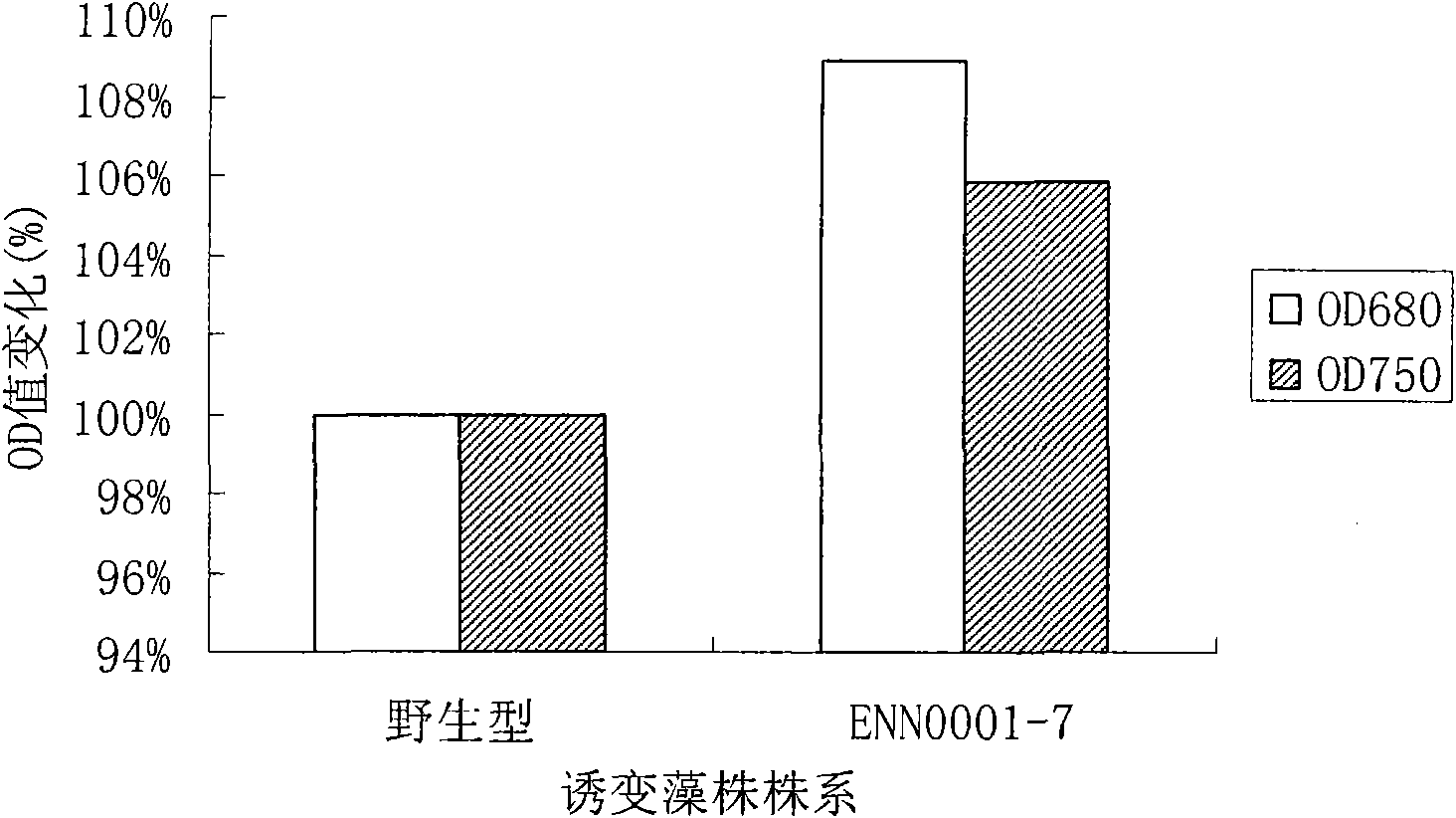

[0079] Example 3 Mutant algal strain ENN0001-7 obtained from screening and wild-type algal strain UTEX LB 999 Comparison of growth rate and chlorophyll content of

[0080] Depend on figure 1 It can be seen that the biomass (OD 750 ) and chlorophyll content (OD 680 ). The normal culture conditions are: 25°C, 4000lux, 12h L / 12h D. The re-screening steps are as follows: the mutagenized algae strains determined by the primary screening are activated by transferring to a solid medium plate once, and a single algal colony is picked and inoculated into a 100ml Erlenmeyer flask added with 20ml EM medium. Cultured for 10 days under normal culture conditions, measured OD 750 value, and adjust the same OD 750 The value is 0.1, inoculated and subcultured in a new 100ml Erlenmeyer flask added with 20ml EM medium, and three parallel samples were set up for each plant. After ten days of culture under normal culture conditions, measure the OD 750 Value, and take 10ml of algae liqui...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com