Power generating apparatus

A power generation device and power generation unit technology, which is applied in the direction of secondary battery charging/discharging, secondary battery repair/maintenance, hydrogen production, etc., can solve the problems of battery explosion and durability reduction, and achieve explosion prevention, low cost, and low cost. The effect of enhancements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] The step of reducing the particle size of the functional material, the step of hydrogenating the functional material, the step of forming a film, and the step of disposing the functional material will be described below.

[0047] When the functional material is a hydrogen storage alloy, materials such as hydrogen storage alloys are generally known such as calcium (Ca), lanthanum (La), magnesium (Mg), nickel (Ni), titanium (Ti), and materials such as vanadium ( V) the third element. These materials are mixed together, and the mixture is melted to manufacture cast hydrogen storage alloys such as La-Ni-based alloys and Mg-Ti-based alloys. Hydrogen is occluded in these alloys, followed by initial pulverization (initial pulverization) or mechanical pulverization to produce fine powders of hydrogen storage materials. Another method for producing fine powders of functional materials is as follows. Metal or alloy particles or Mg particles that are functional materials are pla...

Embodiment 2

[0058] For the use of magnesium (Mg) or magnesium hydride (MgH 2 ) as the hydrolysis and power generation experiments of functional materials are illustrated.

[0059] Attempt to perform the fastest spontaneous hydrolysis reaction experiment with an aqueous solution of a naturally occurring solute. In the experiment, two kinds of samples were used. Sample 1: 1 g of magnesium (Mg) having a particle diameter of 200 μm or more. Sample 2: 1g of magnesium dihydride (MgH 2 ).

[0060] Three aqueous solutions were used as aqueous solutions in the experiment. Aqueous solution 1: water (H 2 O). Aqueous solution 2: 8% citric acid (C 6 h 8 o 7 ) aqueous solution. Aqueous solution 3: 5% bittern (magnesium chloride hexahydrate MgCl 2 ·6H 2 O) Aqueous solution.

[0061] Take 5cc of each of the three aqueous solutions at room temperature (20°C), inject them into each sample in the test tube, and start the experiment. When the spontaneous reaction rate is low, observation and meas...

Embodiment 3

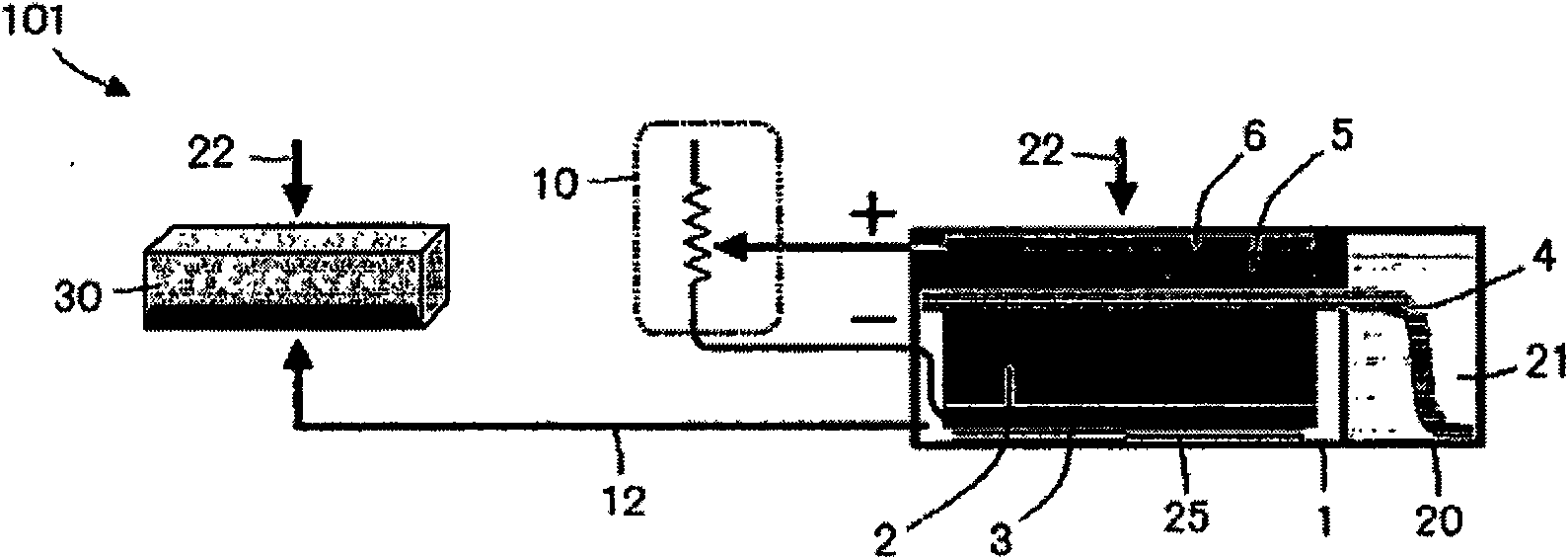

[0075] refer to figure 1 , 2 and 3 describe embodiments of the present invention. figure 1 In the battery element, the positive electrode 6 , the separator 4 and the negative electrode 3 provided with the functional material 2 are laminated to form a battery element and placed in the hydrogen generation container 1 . The wires from the electrodes are connected to the load device 10 through electric wires to conduct current, and the container 1 is connected and communicated with the hydrogen-requiring equipment 30 through the hydrogen conduit 12, thereby constituting the entire device 101 of the present invention.

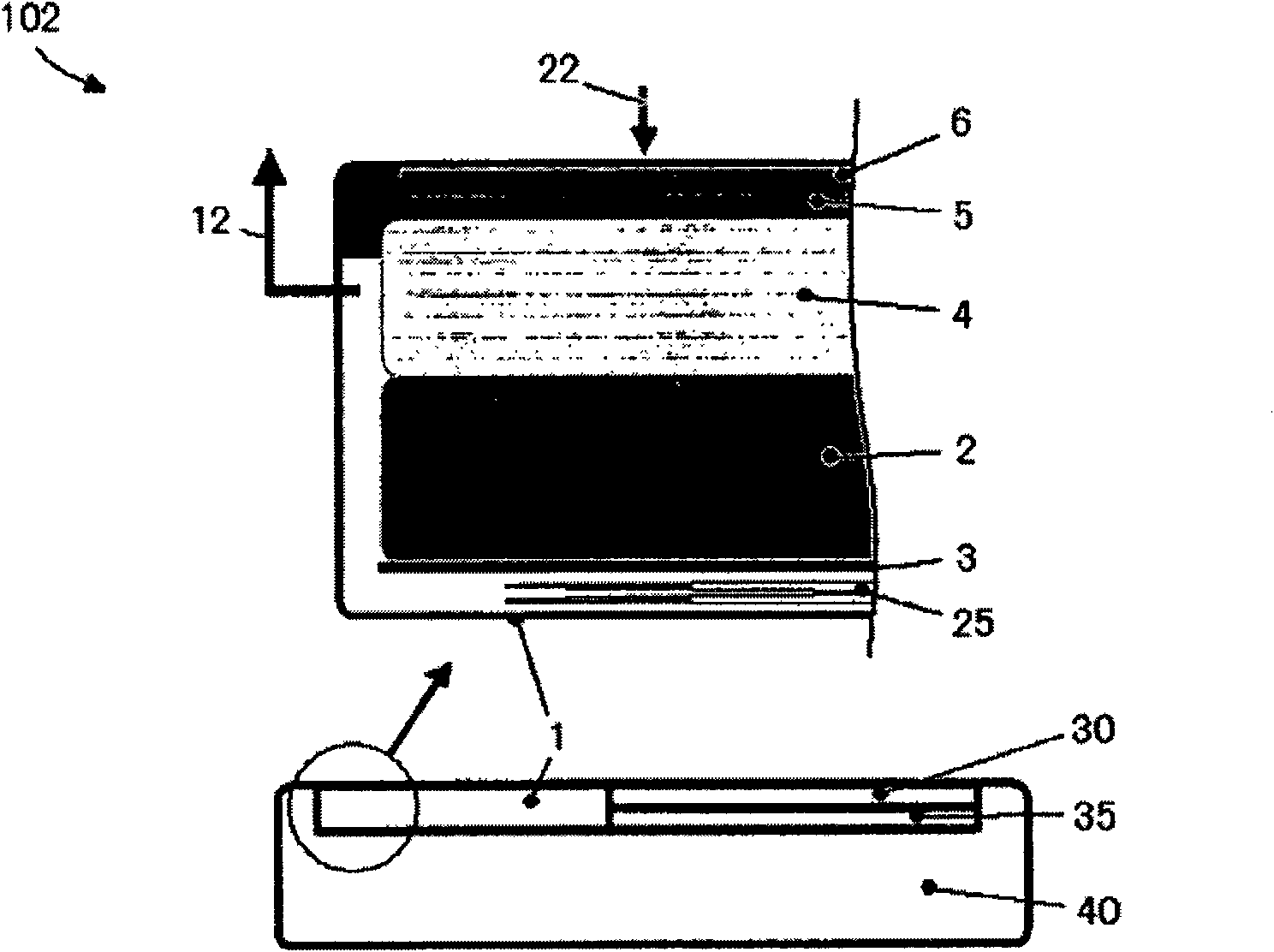

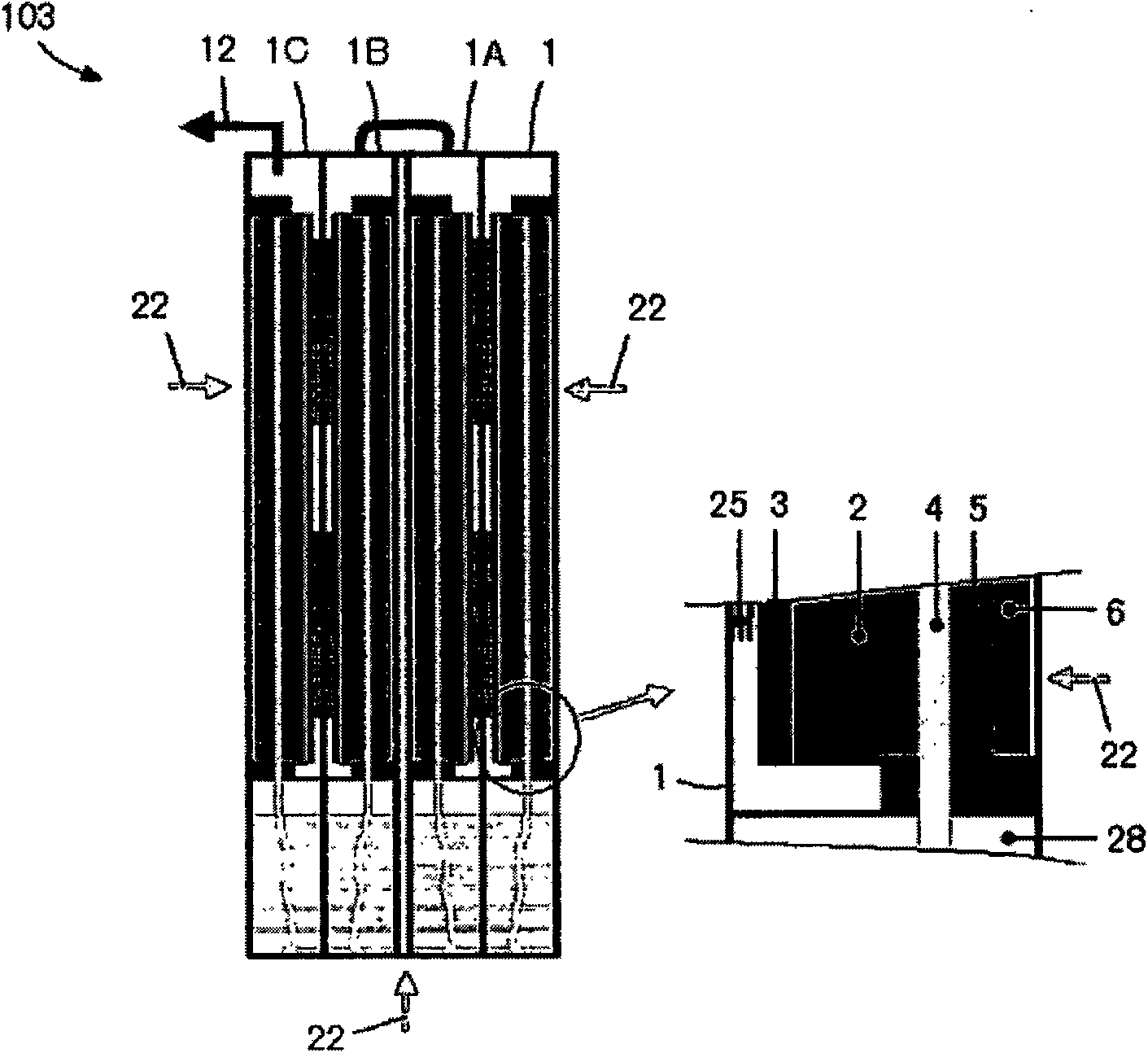

[0076] figure 2 Embodiment 102 of a power supply unit is shown, which is normally provided with the unit in use. In this embodiment 102, the hydrogen generation container 1 is incorporated into the mobile phone 40 . image 3 Embodiment 103 of a medium-to-large-scale device in which hydrogen generation containers 1 are stacked is shown.

[0077] When the hydr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com