Method for synthesizing p-acetamido benzene sulfonyl chloride by phosphorus pentachloride

A technology of acetaminophensulfonyl chloride and phosphorus pentachloride, which is applied in the field of preparation of sulfonamide drug intermediates, can solve the problems of increasing the cost of waste acid treatment, high dosage of chlorosulfonic acid, increasing production costs, etc., and achieve saving of repeated construction investment , high yield and prolong service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

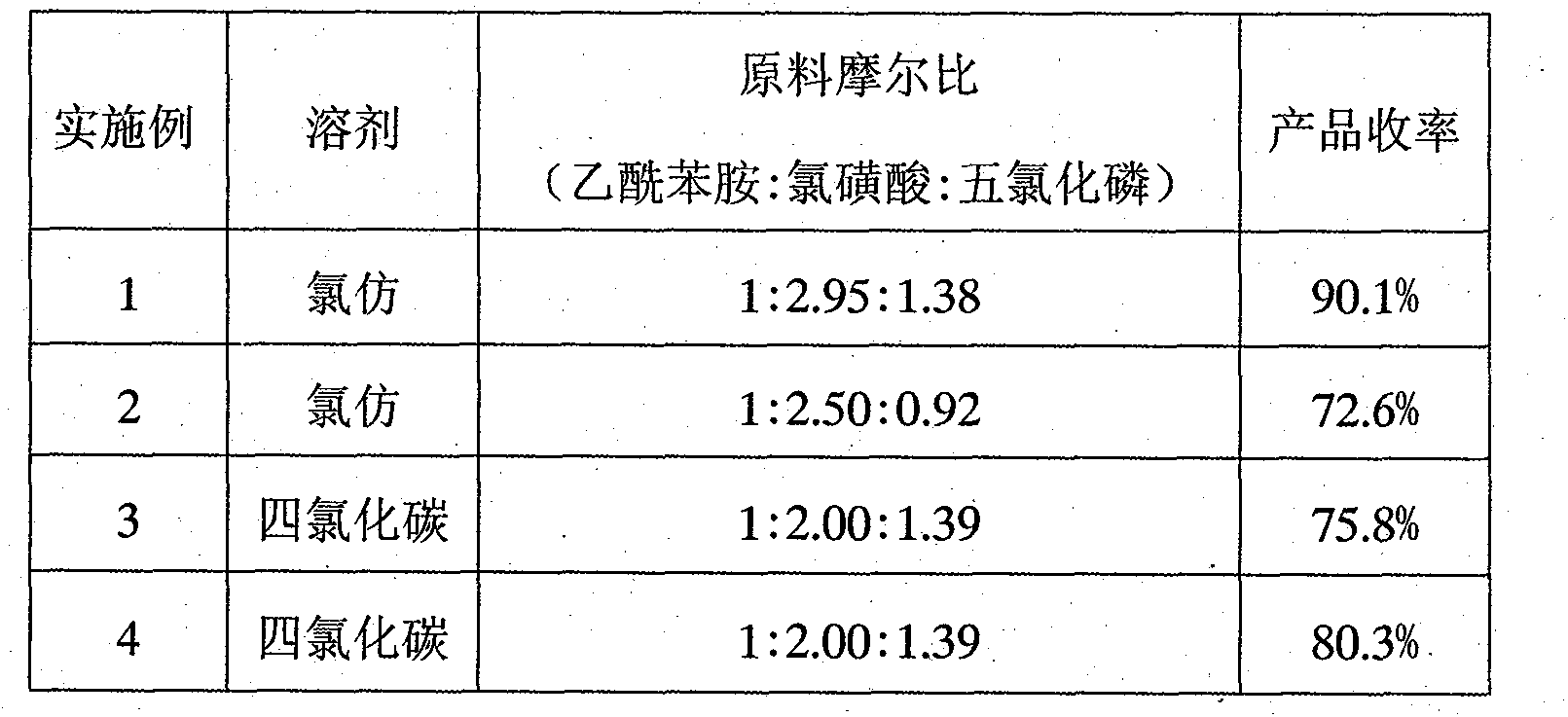

Embodiment 1

[0023] A kind of concrete steps of the method for synthesizing p-acetaminobenzenesulfonyl chloride with phosphorus pentachloride are as follows:

[0024] (1) Sulfonation reaction

[0025] With acetanilide and chlorosulfonic acid as raw materials, the chlorosulfonic acid is first diluted, that is, the volume ratio of chlorosulfonic acid: chloroform organic solvent is 1: 1.1, the chlorosulfonic acid and the chlorosulfonic organic solvent are placed in the container, Stir and mix evenly to prepare a chlorosulfonic acid dilution. Then by acetanilide: the chlorosulfonic acid mol ratio in the chlorosulfonic acid dilution is the ratio of 1: 2.95, in the chlorosulfonic acid dilution, at a temperature of 14°C, add acetanilide (99% purity). After the addition of acetanilide was completed, the mixture was stirred at low temperature for 30 minutes. Then, the temperature was raised to 59° C. while stirring, and the sulfonation reaction was carried out with heat preservation for 60 minut...

Embodiment 2

[0031] A kind of concrete steps of the method for synthesizing p-acetaminobenzenesulfonyl chloride with phosphorus pentachloride are as follows:

[0032] In the (1) step, chlorosulfonic acid: the volume ratio of chloroform organic solvent is 1: 1.0, and acetanilide: the chlorosulfonic acid mol ratio in the chlorosulfonic acid diluent is 1: 2.50, at 12 ℃, in 5 batches Add acetanilide while stirring, continue to stir for 25 minutes, then raise the temperature to 59°C while stirring, and keep it warm for 60 minutes, according to the molar ratio of sulfonated liquid: ammonium chloride desiccant is 1:0.018, stir for 10 minutes;

[0033] In the (2) step, sulfonated oil: the volume ratio of chloroform organic solvent is 1: 0.8, and the acetanilide consumed in the sulfonated oil diluent: the mol ratio of phosphorus pentachloride chlorinating agent is 1: 0.92, stirs Heat up to 59°C, and keep warm for chlorination reaction for 150 minutes;

[0034] In the (3) step, the p-acetamidobenzene...

Embodiment 3

[0036] A kind of concrete steps of the method for synthesizing p-acetaminobenzenesulfonyl chloride with phosphorus pentachloride are as follows:

[0037] In the (1) step, chlorosulfonic acid: the volume ratio of carbon tetrachloride organic solvent is 1: 1.1, and acetanilide: the chlorosulfonic acid mol ratio in the chlorosulfonic acid dilution is 1: 2.00, at 15 ℃, Add acetanilide in 5 batches while stirring, continue to stir for 32 minutes, then raise the temperature to 54°C while stirring, and keep it warm for 65 minutes, according to the molar ratio of sulfonated liquid: ammonium chloride desiccant is 1:0.011, stir for 10 minutes ;

[0038] In the (2) step, sulfonated oil: the volume ratio of chloroform organic solvent is 1: 0.7, and the acetanilide consumed in the sulfonated oil diluent: the mol ratio of phosphorus pentachloride chlorinating agent is 1: 1.39, stirs Heat up to 66°C, and keep warm for chlorination reaction for 180 minutes;

[0039] In the (3) step, the p-a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com