Efficient heat energy utilization method used during fast thermal cracking of straw

A pyrolysis and straw technology, applied in the field of straw pyrolysis, can solve the problems of difficult control conditions, low heat energy utilization rate, and great influence on yield, and achieve the goal of improving heat energy utilization rate, high heat energy utilization rate, and reducing production costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

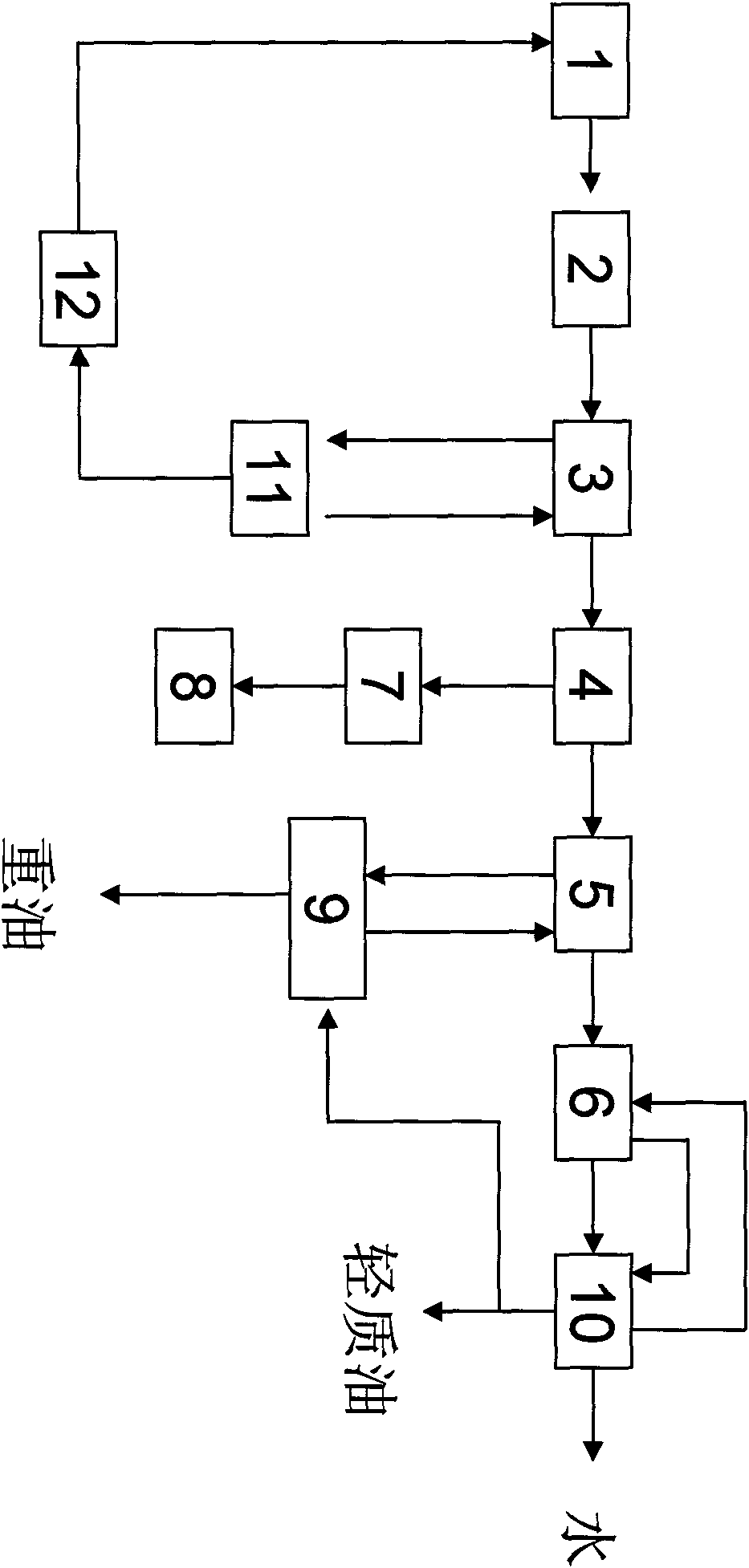

[0018] Example 1. A high-efficiency heat energy utilization method for straw rapid pyrolysis process, such as figure 1 shown. It includes the following steps:

[0019] 1. Drying of crushed straw materials in the trough; 2. Elevating the dried materials to the silo; 3. Transporting the pyrolysis furnace from the silo for thermal cracking; 4. Separating the pyrolysis products from gas to solid through the dust collector of the cracking system; After the gas-solid separation, the gaseous biomass is sent to the rectification scrubber for rectification and washing; 6. The gas discharged from the top of the rectification scrubber is condensed through the top condenser; 7. The charcoal powder after gas-solid separation is sent to the charcoal powder cooler Cooling; 8. Send the cooled carbon powder to the carbon powder dust collector for separation, and the resulting carbon powder is sent to the carbon powder storage tank; 9. The heavy oil discharged from the bottom of the rectifica...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com