Aluminium alloy anodized waste water belt type press filteration system

An anodic oxidation and belt filter press technology, which is applied in the direction of presses, filtration separation, filtration circuits, etc., can solve the problems of energy consumption and low processing efficiency, achieve low maintenance rate, large processing capacity, and improve production efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

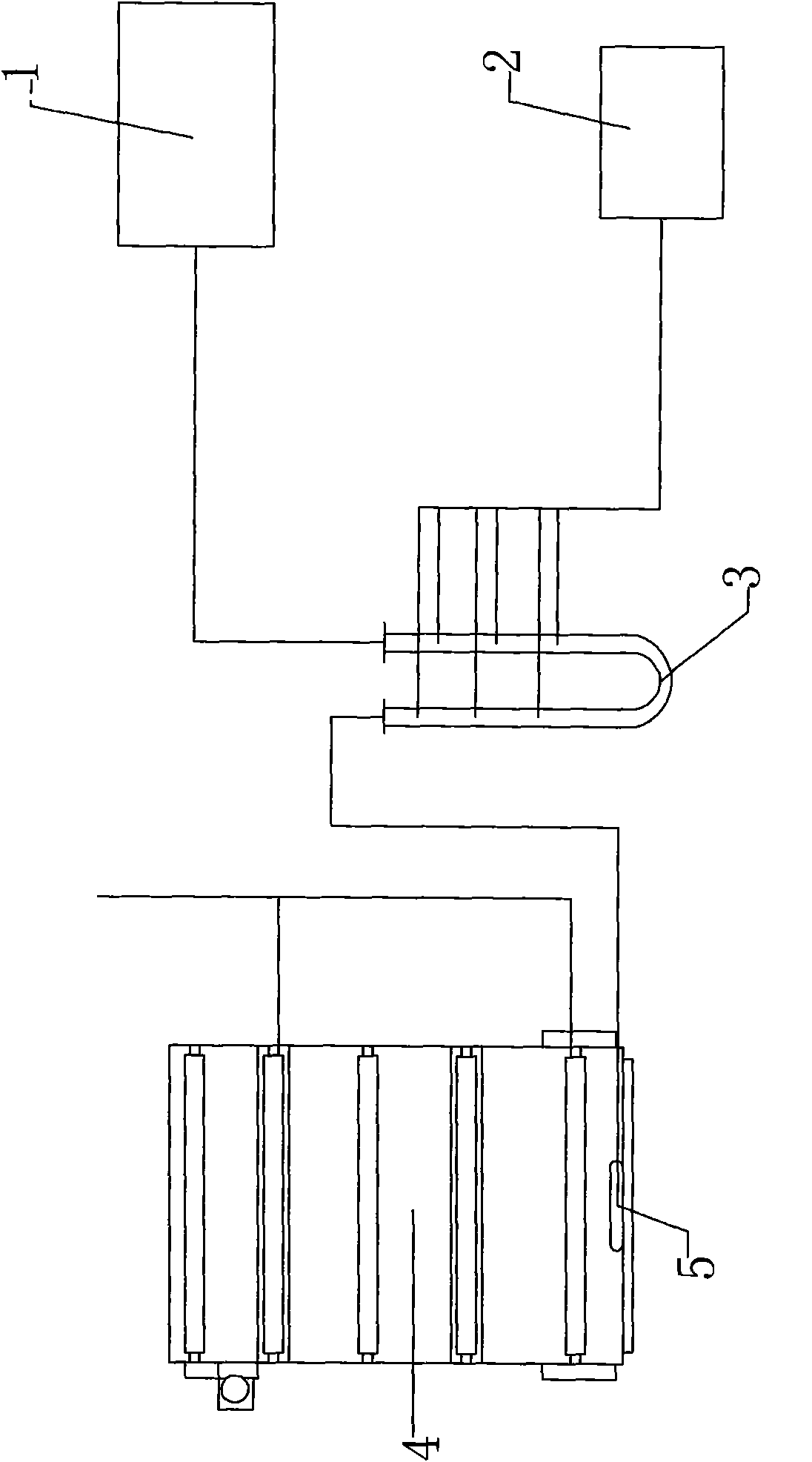

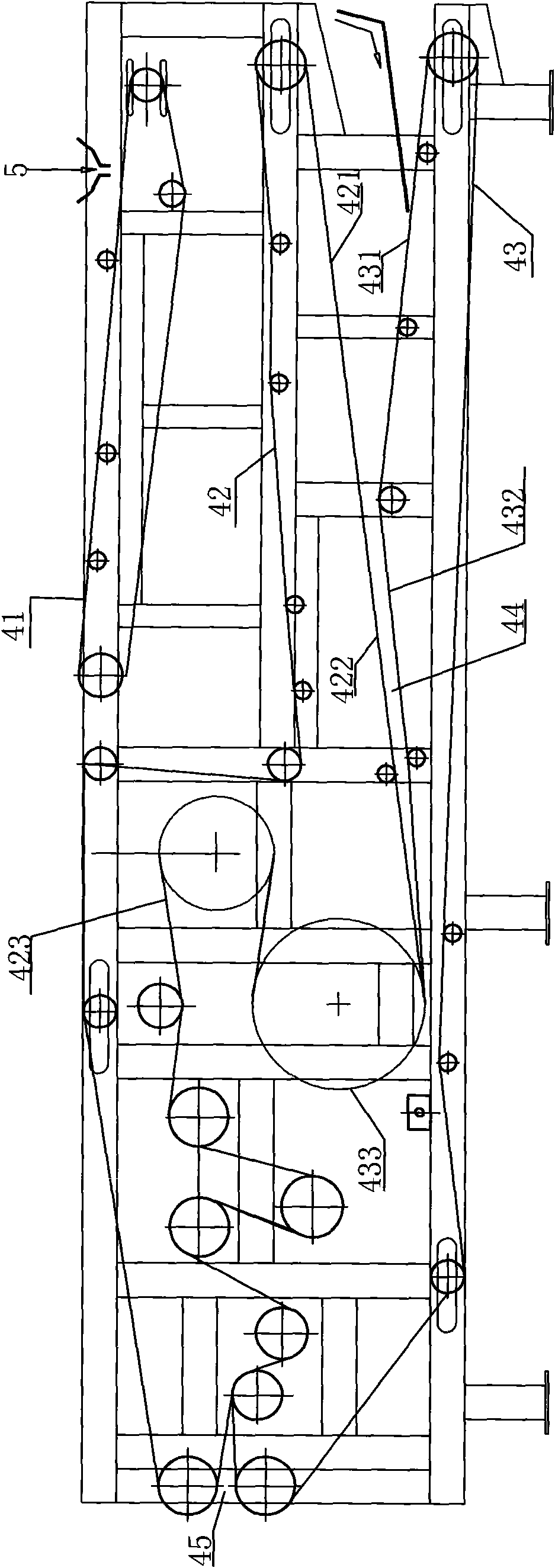

[0012] Below in conjunction with an embodiment the present invention will be further described (see Figure 1-Figure 2 shown):

[0013] The system is mainly composed of a sewage sedimentation tank 1, a flocculant stirring tank 2, a coagulation reactor 3, and a belt filter press 4. The system is mainly divided into the following sections according to the sewage treatment process:

[0014] 1. Chemical pretreatment dehydration section:

[0015] In order to improve the dehydration of sewage, improve the properties of filter cake, and increase the permeability of materials, chemical treatment of sewage is required. First, the sewage is deposited in the sewage sedimentation tank 1, and flocculant is added in the flocculant mixing tank 2, and the sewage The sedimentation tank 1 and the flocculant stirring tank 2 are respectively connected to the coagulation reactor 3 through pipelines. The coagulation reactor 3 can achieve the effect of chemical dosing and flocculation. This design...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com