Hematite low temperature flotation agent and preparation method thereof

A flotation agent, hematite technology, applied in flotation, carboxylate preparation, solid separation, etc., can solve the problems of cost increase, waste of energy, etc., and achieve energy saving, flotation cost reduction, and low operating temperature Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] The process steps for preparing hematite low-temperature flotation agent are as follows:

[0038] 1. Prepare sodium fatty acid solution

[0039] pentadecanoic acid C 14 h 29 Dissolve COOH in water and prepare pentadecanoic acid solution with a concentration of 1.0 mol / L. Mix and stir the prepared pentadecanoic acid solution with an equal volume of 1.0 mol / L sodium hydroxide solution (that is, pentadecanoic acid and hydrogen Sodium oxide equimolar amount mixes), is prepared into the sodium pentadecanoate solution that concentration is 0.5mol / L, and reaction equation is:

[0040] C 14 h 29 -COOH+NaOH=C 14 h 29 -COONa+H 2 o

[0041] Pentadecanoic acid reacts with sodium hydroxide in equimolar amounts.

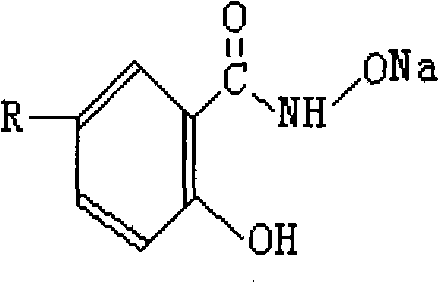

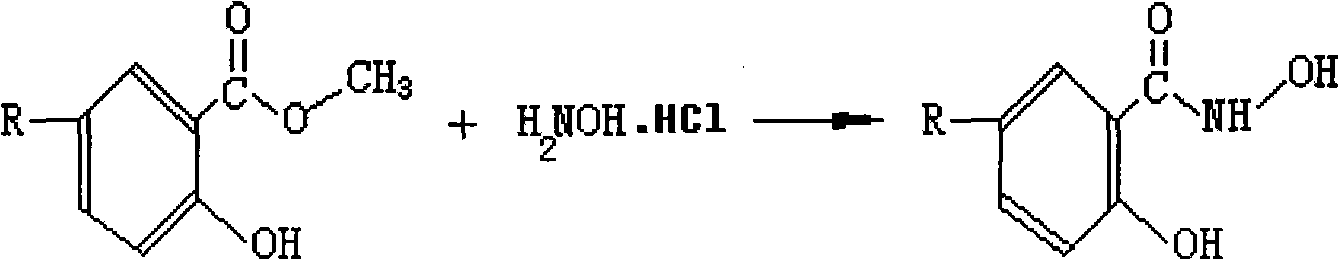

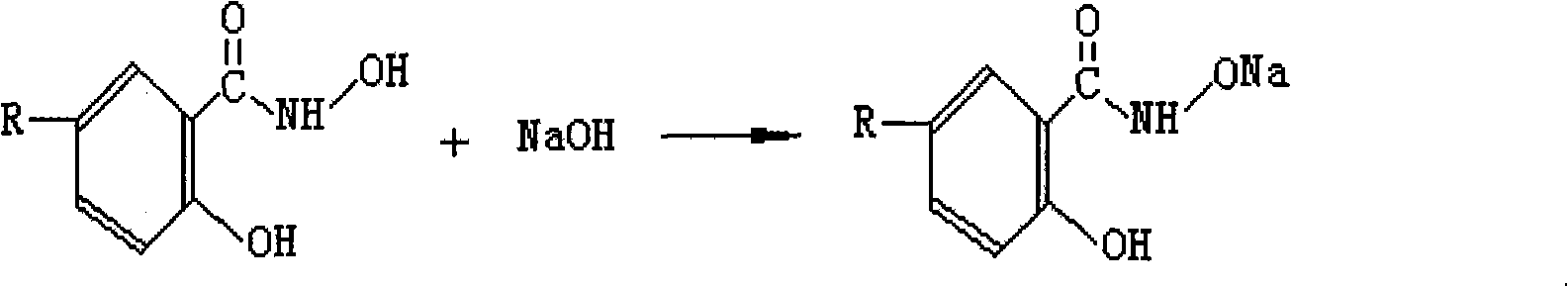

[0042] 2. Preparation of hematite collector agent 2-hydroxy 5-octylbenzoic acid ammonium sodium salt C 8 h 17 C 6 h 3 (OH)CONHONa

[0043] Add methyl 2-hydroxy-5-octylbenzoate C to the reactor 8 h 17 C 6 h 3 (OH)COOCH 3 , add hydroxylamine hydrochloride i...

Embodiment 2

[0055] The process steps for preparing hematite low-temperature flotation agent are as follows:

[0056] 1. Prepare sodium fatty acid solution

[0057] Dodecanoic acid C 11 h 23 Dissolve COOH in water and prepare dodecanoic acid solution with a concentration of 0.5mol / L. Mix and stir the prepared dodecanoic acid solution with an equal volume of 0.5mol / L sodium hydroxide solution (that is, dodecanoic acid and hydrogen Sodium oxide equimolar amount mixes), is prepared into the sodium dodecanoate solution that concentration is 0.25mol / L, and reaction equation is:

[0058] C 11 h 23 -COOH+NaOH=C 11 h 23 COONa+H 2 o

[0059] Dodecanoic acid and sodium hydroxide are in equimolar amounts.

[0060] 2. Preparation of hematite collector agent 2-hydroxy-5-butylbenzoic acid amine sodium salt C 4 h 9 C 6 h 3 (OH)CONHONa

[0061] Add methyl 2-hydroxy-5-butylbenzoate C to the reactor 4 h 9 C 6 h 3 (OH)COOCH 3 , add hydroxylamine hydrochloride in an equimolar amount, stir f...

Embodiment 3

[0074] The process steps for preparing hematite low-temperature flotation agent are as follows:

[0075] 1. Prepare sodium fatty acid solution

[0076] octadecanoic acid C 17 h 35 Dissolve COOH in water and prepare octadecanoic acid solution with a concentration of 1.0 mol / L. Mix and stir the prepared octadecanoic acid solution with 5 mol / L sodium hydroxide solution. Equimolar amounts of octadecanoic acid and sodium hydroxide Mix, and be prepared into the sodium octadecanoate solution that concentration is 0.8mol / L, and reaction equation is:

[0077] C 17 h 35 -COOH+NaOH=C 17 h 35 COONa+H 2 o

[0078] 2. Preparation of hematite collector agent 2-hydroxy-5-methylbenzoic acid ammonium sodium salt CH 3 C 6 h 3 (OH)CONHONa

[0079] Add methyl 2-hydroxy-5-methylbenzoate CH to the reactor 3 C 6 h 3 (OH)COOCH 3 , add hydroxylamine hydrochloride in an equimolar amount, stir for 5 minutes at a stirring rate of 2000 rpm, then add 2.5 mol / L sodium hydroxide solution, stir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com