Sludge dry powder and preparation method thereof

A technology of sludge dry powder and sludge, applied in the field of environmental science, can solve problems such as difficulty in urban sludge treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] The digested sludge obtained from a domestic sewage treatment plant has a moisture content of 80.4%wt; the rice husk ash is obtained from the ash after burning rice husk in an industrial boiler. Mix the sludge containing domestic water, rice husk ash and deodorizing bactericide calcium oxide according to the proportion, and then dry naturally. The drying method is as follows: drying: drying on the concrete floor, the thickness of the mixture is about 10cm, at the highest temperature of 27 ℃, drying for 10 hours on a sunny day, turning once an hour. Flue gas residual heat: Dry the flue gas with residual heat at 180°C for 1 hour. A tunnel-type 12kw microwave dryer was used to irradiate for 4 minutes. See Table 1 for specific data.

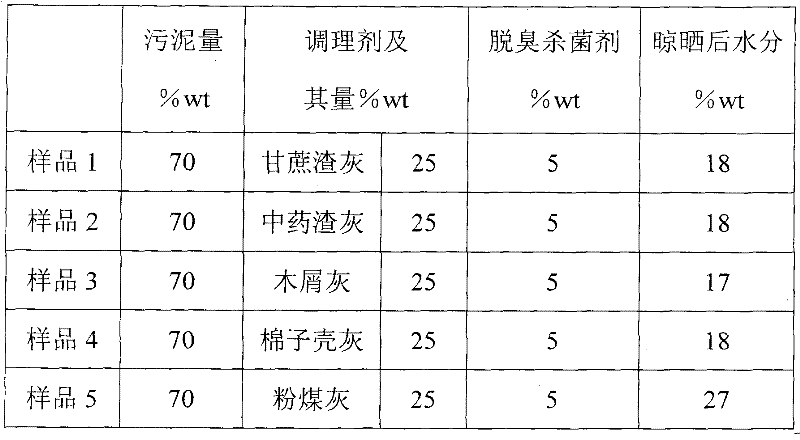

[0017] Table 1

[0018] sludge volume

Embodiment 2

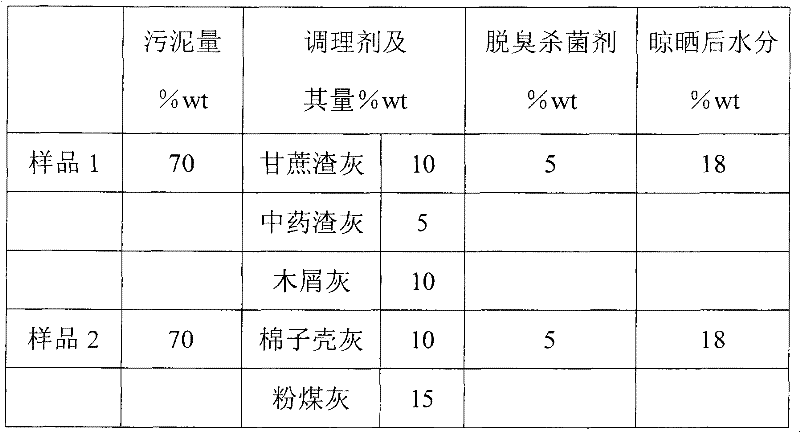

[0020] Sludge taken from a paper mill after sewage treatment had a moisture content of 67.3% wt. Mix the paper-making sludge, conditioning agent and deodorizing bactericide calcium oxide uniformly according to the proportion, and then dry naturally. The types and specific ratios of conditioning agents are shown in Table 2. The drying conditions are as follows: drying on the concrete floor, the thickness of the mixture is about 10cm, at the highest temperature of 28°C, drying for 10 hours on a sunny day, turning once an hour.

[0021] Table 2

[0022]

Embodiment 3

[0024] The sludge after sewage treatment from a printing and dyeing enterprise has a moisture content of 70.4%wt. The paper-making sludge, rice husk ash and deodorizing bactericide are mixed evenly in proportion, and then dried to obtain sludge dry powder. The drying conditions are: dry on the concrete floor, the thickness of the mixture is about 10cm, at the highest temperature of 27 ℃, dry for 10 hours on a sunny day, and turn it once an hour. 140 ℃ boiler waste heat drying for 1h. A tunnel-type 12kw microwave dryer was used to irradiate for 4 minutes. See Table 3 for specific data.

[0025] table 3

[0026]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com