Pesticide water dispersible granule and preparation method thereof

A technology of dispersing granules and dispersing agents, which is applied in the fields of pesticides, botanical equipment and methods, biocides, etc., can solve the requirements for water dispersible granules of ethiprole that have not yet been reported, agglomeration, layered precipitation, and equipment requirements. High-level problems, to achieve the effect of environmental protection and ecological environment quality improvement, high suspension rate and good dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

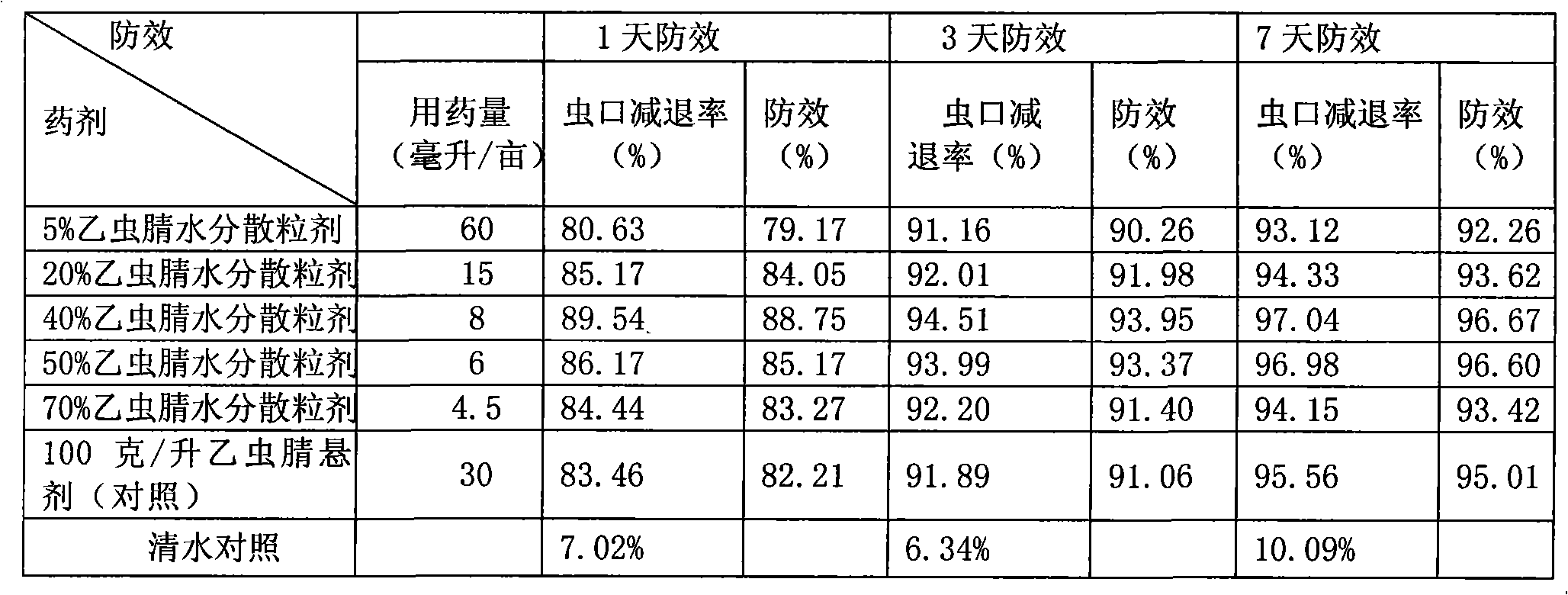

Examples

Embodiment 1

[0033] Example 1: 5% ethiprole water dispersible granules

[0034] Take 5.6Kg of 90% ethiprole original drug, 5Kg of wetting agent sodium lauryl sulfate, 8Kg of dispersant sodium naphthalenesulfonate formaldehyde condensate, 2Kg of disintegrating agent ammonium sulfate, 1Kg of binder carboxymethyl cellulose, stable Agent BHT 2Kg, pottery clay 76.4Kg, after mixing, jet milling, adding 20Kg of water, mixing, kneading, granulating, drying, and sieving to obtain ethiprole water-dispersible granules.

[0035] The main technical indicators of detection are as follows: moisture 0.8%, PH value range 6.5, wetting time 42 seconds, sieve analysis (through 75μm test sieve) 96%, suspension rate 85%, disintegration time 63 seconds, particle size range (0.1 ~ 2.0mm ) 95.5%, persistent foaming volume 18ml, thermal storage stability (54±2°C, 14d) decomposition rate 3.2%.

Embodiment 2

[0036] Example two: 20% ethiprole water dispersible granules

[0037] Take 21.2Kg of 95% ethiprole original drug, 2Kg of wetting agent sodium lauryl polyoxyethylene ether sulfate, 4Kg of wetting agent sodium lauryl sulfate, 6Kg of dispersant calcium lignosulfonate, and 6Kg of dispersant Sodium naphthalenesulfonate 3Kg, disintegrant magnesium chloride 2Kg, bentonite 7Kg, binder dextrin 1Kg, stabilizer triphenyl phosphate 2Kg, bentonite 51.9Kg, ethiprole water-dispersible granules were prepared according to the preparation method of Example 1.

[0038] The main technical indicators of detection are as follows: moisture 0.75%, pH value range 6.8, wetting time 38 seconds, sieve analysis (through 75μm test sieve) 96.4%, suspension rate 89%, disintegration time 46 seconds, particle size range (0.1 ~ 2.0mm ) 96%, persistent foaming volume 15ml, thermal storage stability (54±2°C, 14d) decomposition rate 2.5%.

Embodiment 3

[0039] Embodiment three: 40% ethiprole water-dispersible granules

[0040] Take 44.5Kg of 91% ethiprole original drug, 5Kg of wetting agent sodium lauryl sulfate, 10Kg of dispersant sodium naphthalenesulfonate formaldehyde condensate, 4Kg of disintegrating agent bentonite, 2Kg of binder polyvinyl alcohol, and 2Kg of stabilizer BHT , filler silica 33Kg, according to the preparation method of Example 1, ethiprole water-dispersible granules were obtained.

[0041] The main technical indicators of detection are as follows: moisture 0.7%, pH value range 6.7, wetting time 36 seconds, sieve analysis (through 75μm test sieve) 96.8%, suspension rate 91%, disintegration time 43 seconds, particle size range (0.1 ~ 2.0mm ) 97%, persistent foaming volume 13ml, thermal storage stability (54±2°C, 14d) decomposition rate 2.6%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com