Cleaning and producing technology of turmetic produced saponin

A clean production, saponin technology, applied in water/sewage multi-stage treatment, steroids, heating water/sewage treatment, etc., can solve the problems of pollution, water pollution, poor biodegradability of wastewater, etc., to improve the concentration efficiency, The effect of saving resources and low residues of active ingredients

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

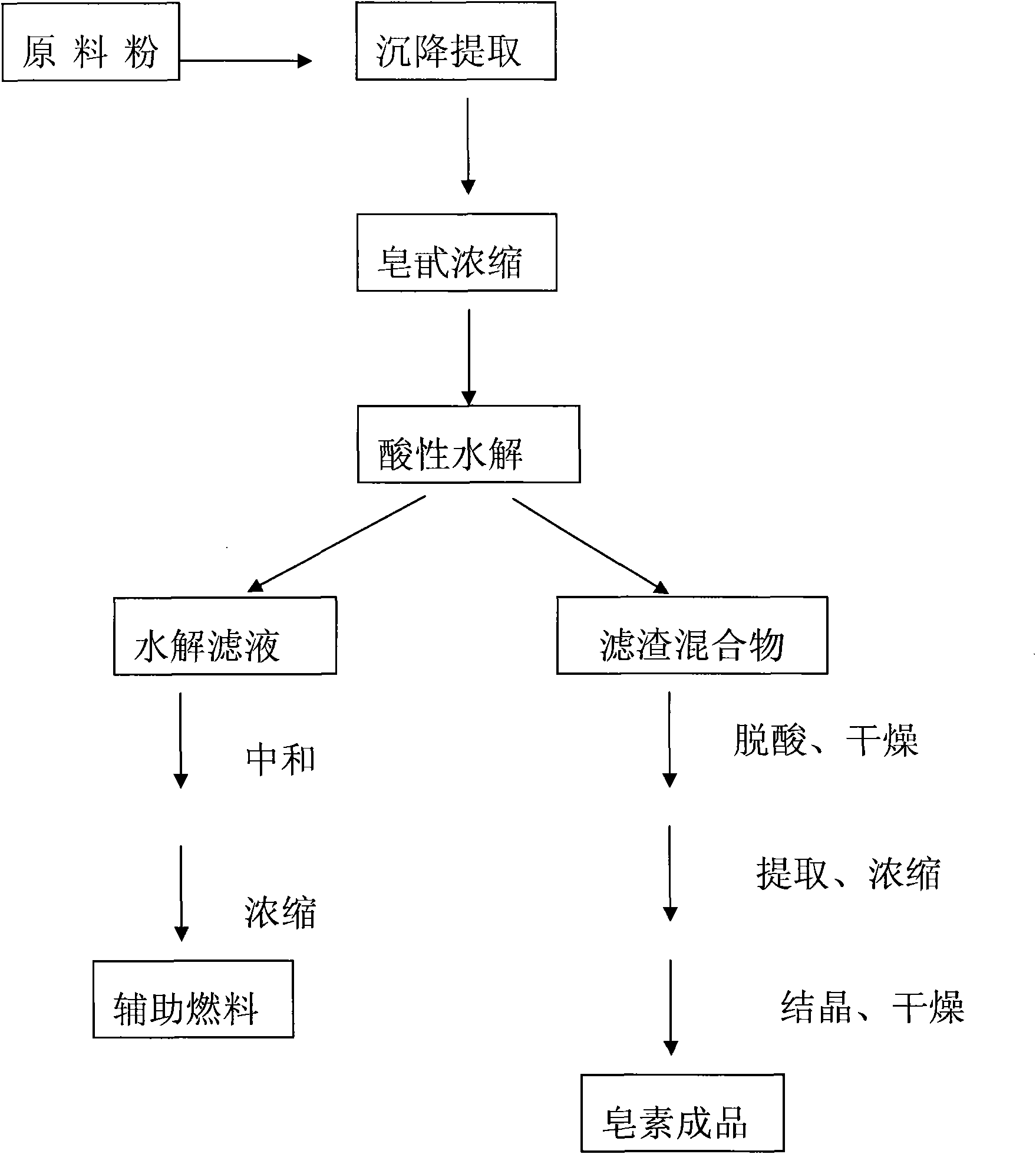

Image

Examples

Embodiment 1

[0017] Weigh 400kg and determine the content according to DB42 / T32.2-2002. The yellow ginger is washed, pulverized with 2 times the amount of water, and the pulverized material passes through the sedimentation separator many times to separate the saponin solution from the fiber and starch. 185 kg of a mixture of wet starch and cellulose was obtained, which was tested to contain 23.4 g of saponin, and the residual saponin was 0.86%. The separated saponin solution is added with an appropriate amount of polyaluminum iron sulfate flocculant to make the precipitation complete, and then separated by a centrifuge to make the saponin concentration reach 35-50%. Add 2-3% sulfuric acid solution to the concentrated saponin, pressurize to 0.2-0.3MPa, hydrolyze for 2-4 hours, and filter; add 1 / 3-1 / 2 of the filtered wastewater to the hydrolysate , And then add an appropriate amount of sulfuric acid solution to control the acidity at 1-2%, and perform pressurized hydrolysis under the above c...

Embodiment 2

[0020] Weigh 400kg and determine the content according to DB42 / T32.2-2002. The yellow ginger is washed and pulverized with twice the amount of water. The pulverized material passes through a sedimentation separator many times to separate the saponin solution from the fiber and starch. 171 kg of a mixture of wet starch and cellulose was obtained, which was tested to contain 24.0 g of saponin and the residual saponin was 0.91%. The separated saponin solution is added with an appropriate amount of polyacrylamide flocculant to make the precipitation complete, and then separated by a centrifuge to make the saponin concentration reach 35-50%. The filtered 1 / 3-1 / 2 of the wastewater is added to the hydrolyzed product, then an appropriate amount of sulfuric acid solution is added to control the acidity at 1-2%, and pressure hydrolysis is carried out under the above conditions to obtain a filter residue mixture and filtrate. The filter residue mixture was deacidified and dried to obtain...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com