Method for preparing diesel component by catalytic cracking of coal tar light fraction

A catalytic cracking and catalytic cracking unit technology, which is applied in the field of catalytic cracking of light fractions of coal tar to prepare diesel components, can solve the problems of affecting the stability of diesel oil, the total yield of liquid products is not high, and the economic benefits are not obvious.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

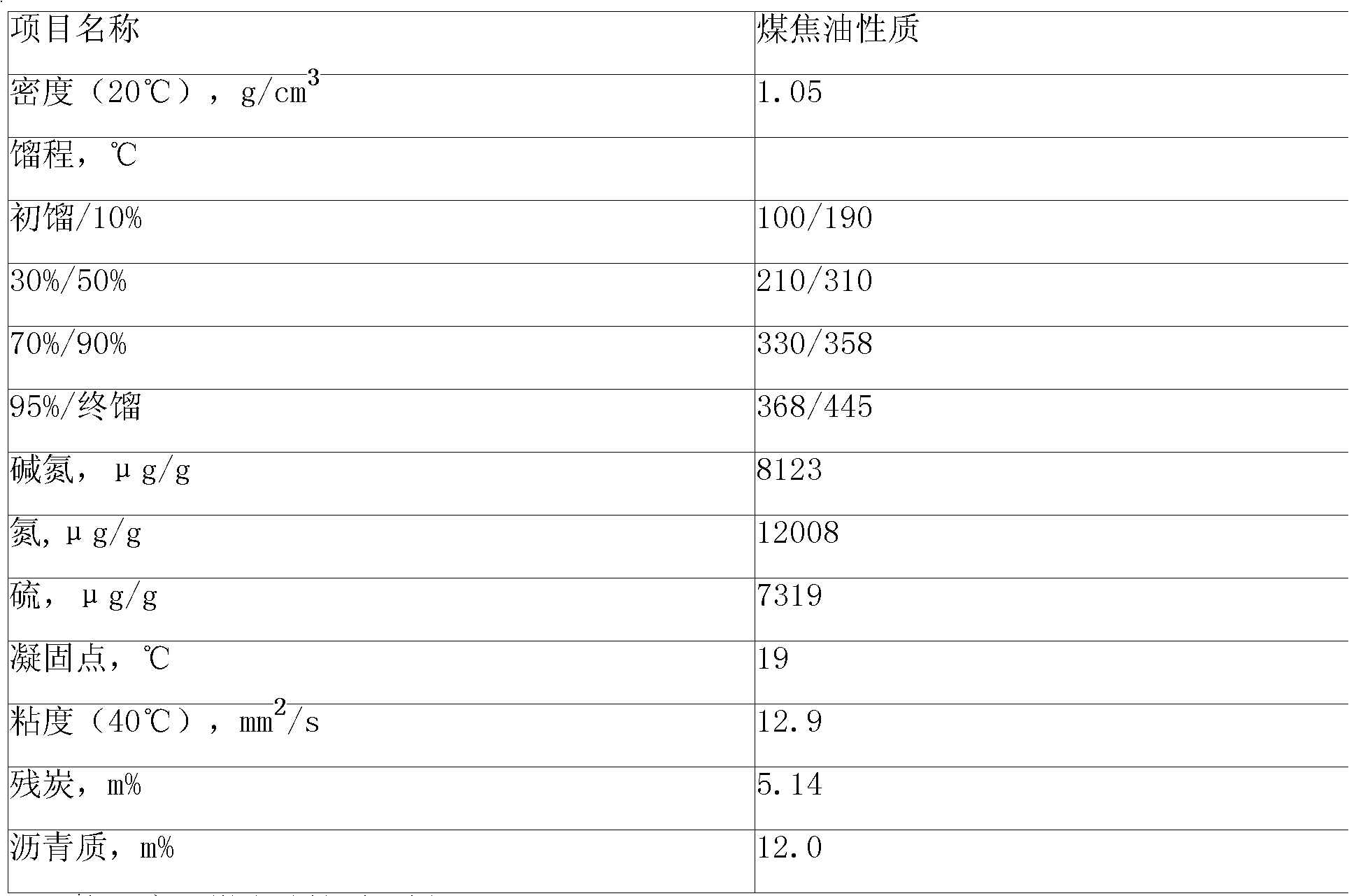

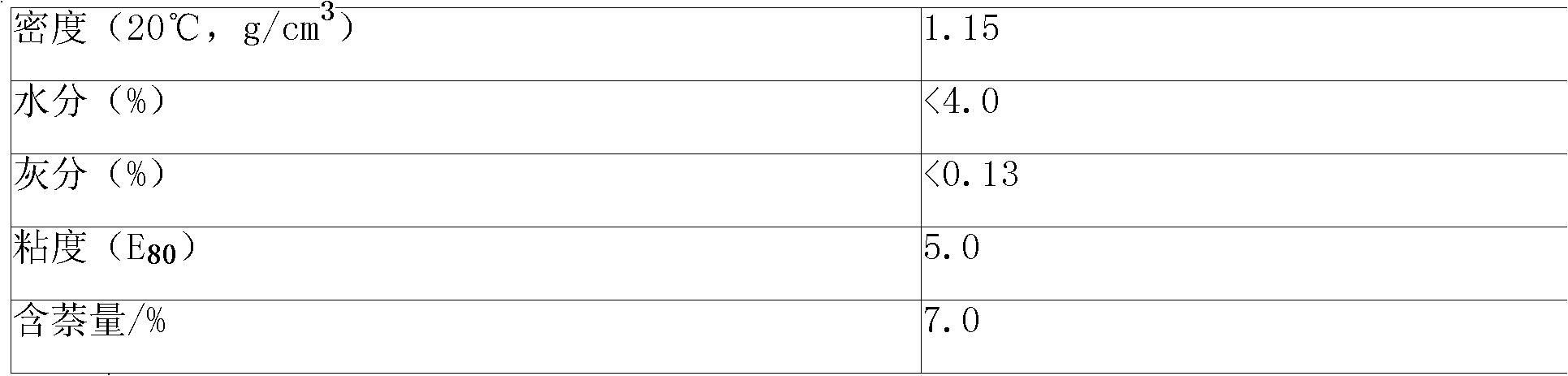

[0042] The coal tar used is medium temperature coal tar; the collected light fraction is 160-320°C fraction, 350g in total.

[0043] Put the light fraction of coal tar in an upflow fixed-bed reactor at a temperature of 420°C, a pressure of 0.15Mpa, and an oil-gas space velocity of 1h -1 Under the conditions of reaction, the diesel component is obtained, and its properties are shown in Table 4.

[0044] The catalyst used in the upflow fixed-bed reactor is a high-silicon Y-type molecular sieve catalyst loaded with La, with a pore volume of 0.25-0.30ml / g and a specific surface area of 150m 2 / g, the rare earth element La accounts for 2% of the weight of the catalyst.

[0045] Table 4 embodiment 1 gained diesel oil component property analysis data

[0046] project name

Embodiment 2

[0049] The coal tar used is medium temperature coal tar; the collected light fraction is 180-310°C fraction, 300g in total.

[0050] Put the light fraction of coal tar in an upflow fluidized bed reactor at a temperature of 400°C, a pressure of 0.3Mpa, and an oil-gas space velocity of 0.8h -1 Under the condition of reaction, diesel oil component can be obtained.

[0051] The catalyst used in the upflow fluidized bed reactor is a high silicon Y-type molecular sieve catalyst loaded with Ce, with a pore volume of 0.25-0.50ml / g and a specific surface area of 100m 2 / g, the rare earth element Ce accounts for 3% of the weight of the catalyst.

Embodiment 3

[0053] The coal tar used is low-temperature coal tar; the collected light fraction is 180-310°C fraction, 290g in total.

[0054] Put the light fraction of coal tar in an upflow fixed-bed reactor at a temperature of 450°C, a pressure of 0.05Mpa, and an oil-gas space velocity of 2.5h -1 Under the condition of reaction, diesel oil component can be obtained.

[0055] The catalyst used in the upflow fixed-bed reactor is a high-silicon Y-type molecular sieve catalyst loaded with Nd, with a pore volume of 0.25-0.40ml / g and a specific surface area of 200m 2 / g, the rare earth element Nd accounts for 5% of the weight of the catalyst.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Pore volume | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Pore volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com