Antihepatitis medicament, preparation method thereof and use thereof

An anti-hepatitis and drug technology, applied in the field of medicine, to achieve good release performance, improve bioavailability, and easy absorption into the blood circulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 118

[0043] Example 118 Preparation of α-Diammonium Glycyrrhizinate 4 Hydrate Mix 300 g of 18β-monoammonium glycyrrhizinate and 1600 ml of 20% sodium hydroxide or potassium hydroxide solution, heat up and reflux for 8 hours, cool down to room temperature, adjust the pH with hydrochloric acid= 1-2, add 2000ml of n-butanol, stir for 45min, static layering, separate the water layer, wash the organic layer twice with 1N hydrochloric acid solution, wash with water, separate the water layer, then pass through the organic layer with ammonia to make the pH = 8, Glacial acetic acid adjusts the pH to about 5.8, separates the lower layer of feed liquid, and evaporates n-butanol under reduced pressure to obtain the crude product; add the crude product to 90% ethanol, heat to reflux, the solution becomes clear, decolorize with activated carbon, filter, add isopropanol, low temperature Cool, crystallize, filter, and dry the solid at about 30°C for 72 hours to obtain 156.2g of off-white crystallin...

Embodiment 2

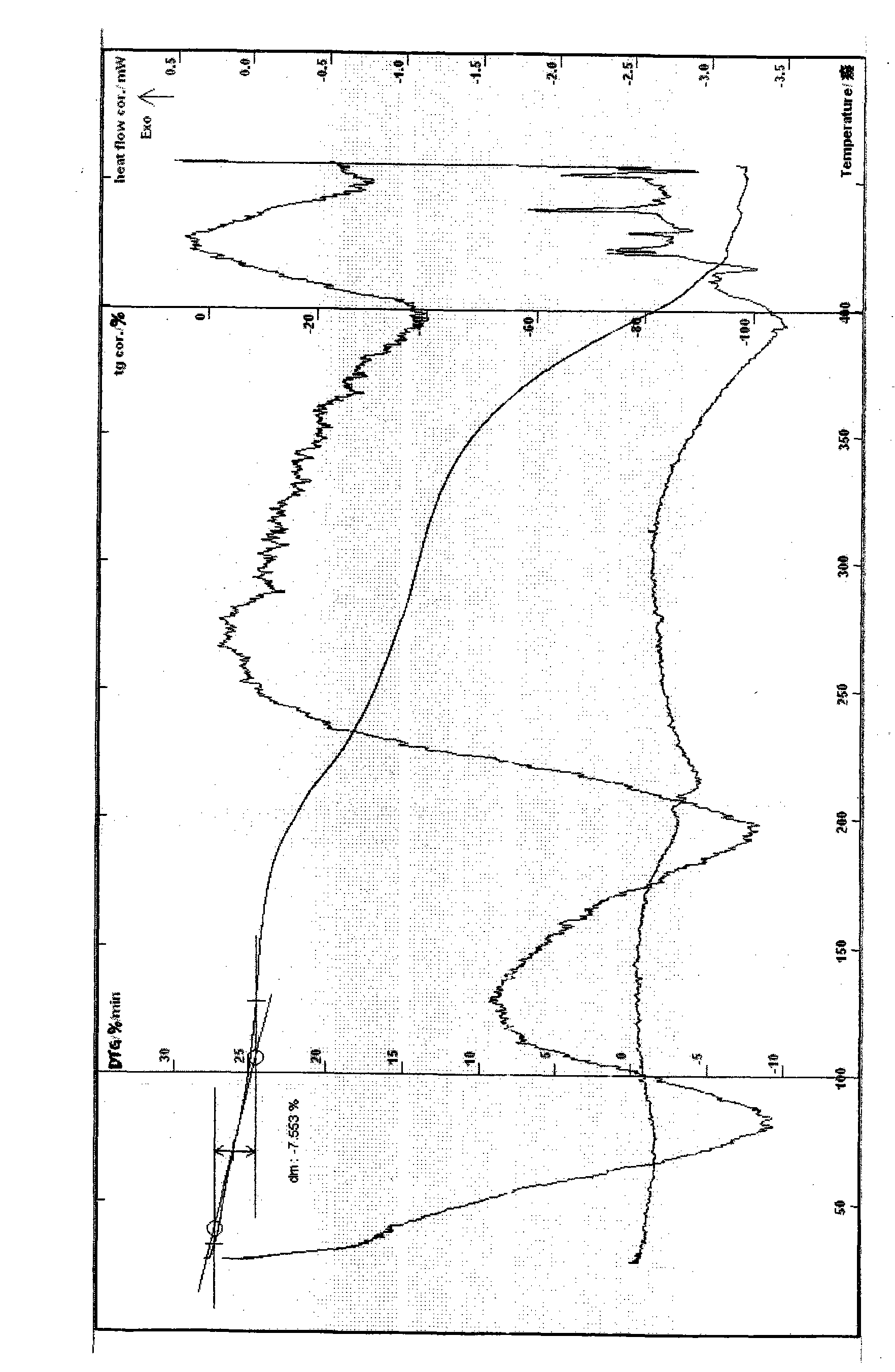

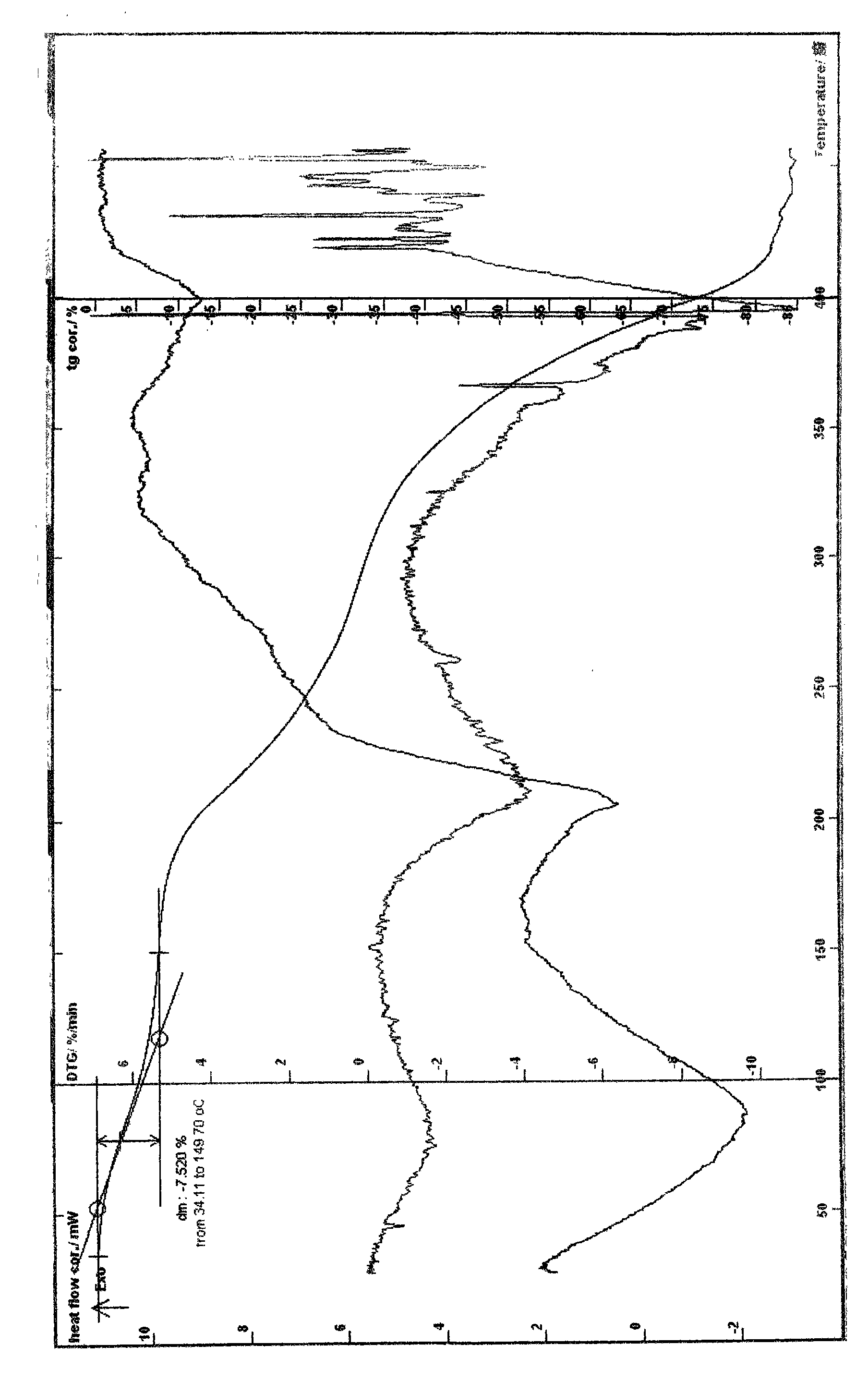

[0044] Example 2 Preparation of 18β-diammonium glycyrrhizinate 4 hydrate Weigh 57g of ammonium bicarbonate in a 500ml reaction bottle, add 180ml of water to dissolve, gradually add 605g of 18β-monoammonium glycyrrhizinate under stirring, stir for 2 hours, heat to 50 ~70°C, stir for 30min, add 350ml of absolute ethanol, heat and reflux for 30min, decolorize the activated carbon, filter out the activated carbon, add 100ml of isopropanol, cool and place, white crystals precipitate, filter, dry at 30°C for 72 hours to obtain 16g of off-white powder , to get 495g of 18β-diammonium glycyrrhizinate, yield 82%; melting point: 145 ° C decomposition (uncorrected), UV spectrum: λ H2O max 257nm (lgε>4, H 2 O); ESI-MS: m / z: 857,821; Karl Fischer's method of measuring moisture is 7.83%, TG-DTG: platform weight loss is about 7.52%, which is the same as the result that the sample contains 4 crystal waters (theoretical value 7.76%) Within the margin of error (see attached figure 2 ), eleme...

Embodiment 318

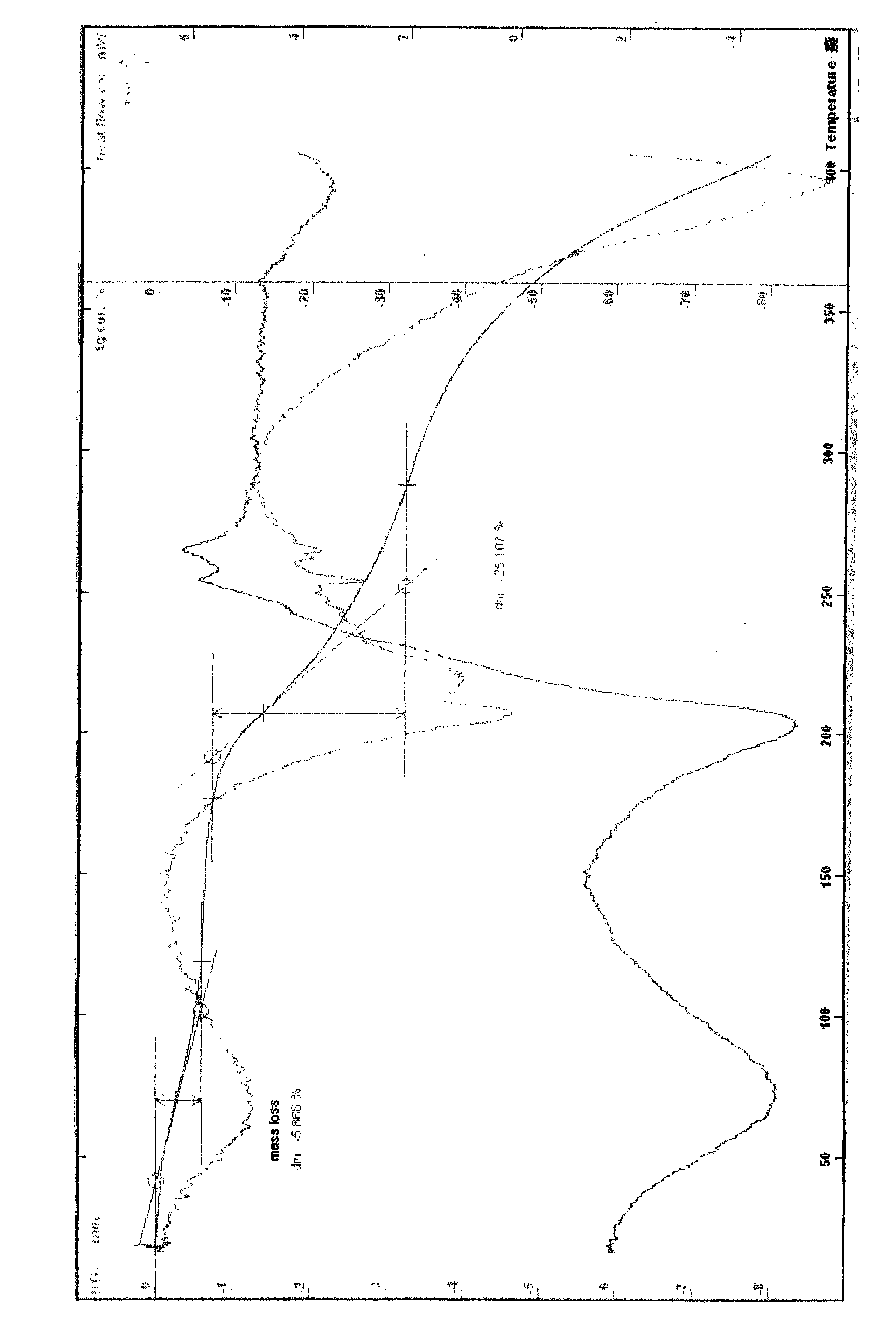

[0045]Example 318 Preparation of α-Diammonium Glycyrrhizinate Trihydrate Put 100 g of triammonium glycyrrhizinate and 500 ml of 5M sodium hydroxide or 5M potassium hydroxide solution in a reaction flask, heat up and reflux for 7-8 hours, then cool down to room temperature , adjust PH=1~3 with 3M sulfuric acid respectively, add n-butanol, stir, stand still, separate the water layer, the organic layer is washed with the acidic aqueous solution of pH=1~2, and the organic layer after washing is passed ammonia gas, makes When the pH is between 7.0 and 8.1, adjust the pH between 5.5 and 6.2 with acetic acid solution, separate the material liquid in the lower layer, evaporate n-butanol under reduced pressure to obtain a solid, add the solid to 90% ethanol, and heat to reflux , add 90% ethanol to make the solution clear, decolorize activated carbon, filter, add 30ml of isopropanol and 10ml of acetone to the filtrate, cool, let stand for crystallization, filter, dry the solid at about 6...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com