Casting method of cast steel cooling plate

A cooling plate and steel casting technology, which is applied to the casting of steel casting cooling plates and the fields of metallurgical high temperature furnaces, can solve the problems of unfavorable cooling plate efficient cooling, shortening the service life of cooling plates, increasing resource consumption, etc. and inner surface oxidation, saving production cost and improving cooling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

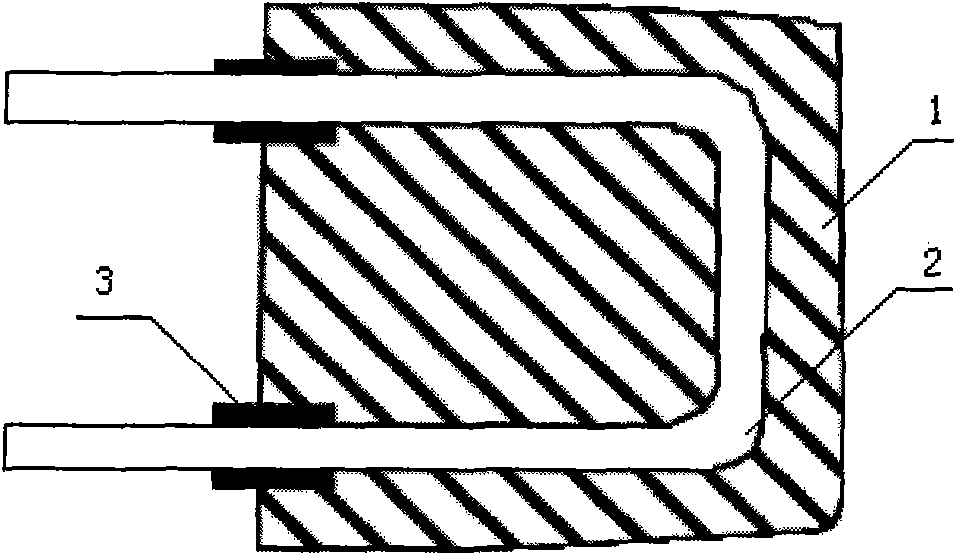

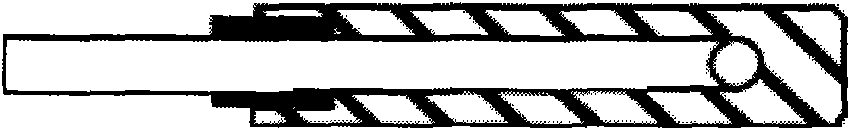

[0033] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0034] In the casting method of the cast steel cooling plate of the present invention, the material of the cooling water pipe is selected as cast steel, and the cast steel material is used to pour the steel brick body at the same time, and the specific pouring steps are:

[0035](1) The molten steel is smelted in an intermediate frequency induction furnace (3 tons of bulk density). At the end of the molten steel smelting, the slagging agent is added twice to make it evenly cover the surface of the molten steel. The total consumption of the slagging agent is added at a rate of 1kg / ton of molten steel. , the slagging agent contains 80-85% calcium oxide and 10-15% magnesium oxide;

[0036] (2) Before the molten steel is released from the furnace, ferrosilicon alloy nuggets with a particle size of 30-40 mm are added to the induction furnace at one time. The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com