Method for preparing ordered mesoporous material by utilizing bentonite

A technology of mesoporous materials and bentonite, applied in the direction of crystalline aluminosilicate zeolite, etc., can solve the problems of low specific surface area of Al-MCM-41, high concentration of surfactant, less amount of bentonite, etc., to achieve low price, Raw materials are easy to obtain and the pores are uniform

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

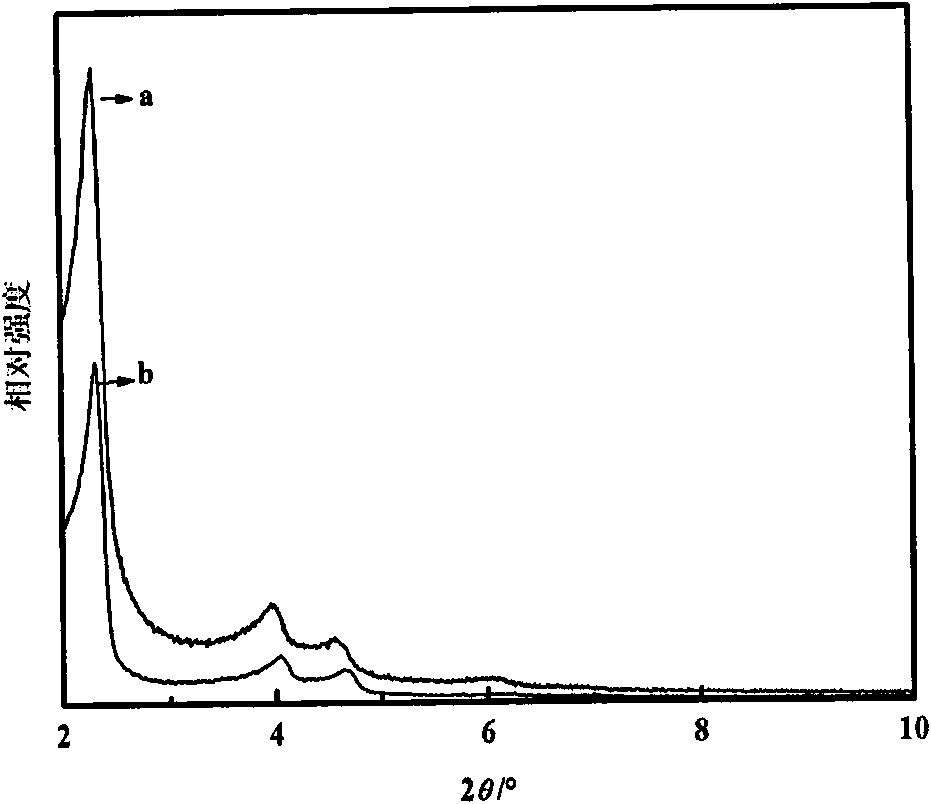

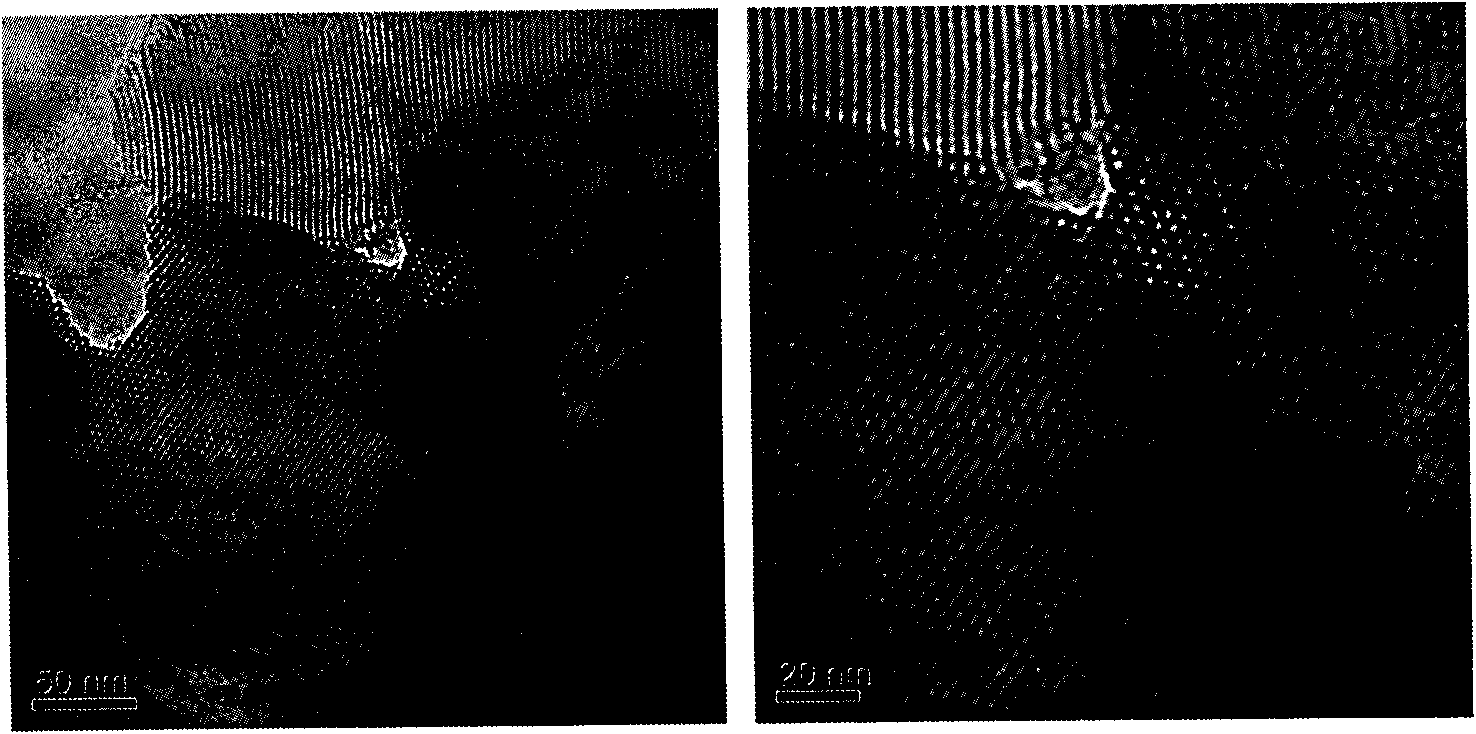

Embodiment 1

[0018] Mix 15g of bentonite raw material passing through a 200-mesh sieve with NaOH solid at a mass ratio of 1:1.25, roast at 600°C for 2h, add 300mL of deionized water after natural cooling, let stand for 16h, and then leaching 80mL of supernatant liquid gradually Add dropwise into the solution of cetyltrimethylammonium bromide, continue to stir, adjust the pH value of the mixed solution to 11 with hydrochloric acid, transfer the mixed solution to the reaction kettle for 24 hours at 110°C to crystallize for 24 hours to obtain the precursor, the precursor After suction filtration, washing, drying for 4 hours, calcination at 540°C for 6 hours, and natural cooling to room temperature, the ordered mesoporous material Al-MCM-41 was obtained with a silicon-aluminum ratio of 13.72. The specific surface area of the prepared Al-MCM-41 can be as high as 840m 2 g -1 , the pore volume can reach 1.04cm 3 g -1 .

Embodiment 2

[0020] Mix 15g of bentonite raw material passed through a 200-mesh sieve with NaOH solid at a mass ratio of 1:1, roast at 600°C for 2h, add 300mL of deionized water after natural cooling, let stand for 12h, and then leaching 80mL of supernatant Add dropwise into the tetradecyltrimethylammonium chloride solution, continue to stir, adjust the pH value of the mixed solution to 9 with hydrochloric acid, and transfer the mixed solution to a reaction kettle for 24 hours at 160°C to obtain a precursor. After suction filtration, washing, drying for 4 hours, calcination at 540°C for 6 hours, and natural cooling to room temperature, the ordered mesoporous material Al-MCM-41 was obtained with a silicon-aluminum ratio of 32.66. The specific surface area of the prepared Al-MCM-41 can be as high as 1000m 2 g -1 above, the pore volume can reach 1.00cm 3 g -1 above.

Embodiment 3

[0022] Mix 15g of bentonite raw material passing through a 200-mesh sieve and NaOH solid at a mass ratio of 1:1.5, roast at 600°C for 2h, add 300mL of deionized water after natural cooling, let stand for 20h, and then leaching 80mL of supernatant liquid one by one Add dropwise into the solution of octadecyltrimethylammonium bromide, continue to stir, and adjust the pH value of the mixed solution to 9 with hydrochloric acid. After 30 minutes, transfer the mixed solution to a reaction kettle for crystallization at 130°C for 24 hours to obtain a precursor. The body was filtered, washed, dried for 4 hours, calcined at 540°C for 6 hours, and naturally cooled to room temperature to obtain an ordered mesoporous material Al-MCM-41 with a silicon-aluminum ratio of 22.69. The specific surface area of the prepared Al-MCM-41 can be as high as 721m 2 g -1 , the pore volume can reach 0.88cm 3 g -1 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com