Continuous coiling and coating device of solar selective absorbing film

A coating device and selective technology, applied in the field of solar thermal collectors, can solve the problems of difficult to ensure consistent coating parameters, single coating material, pollution, etc., and achieve rich human-machine interface, high coating efficiency, and coating quality. Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

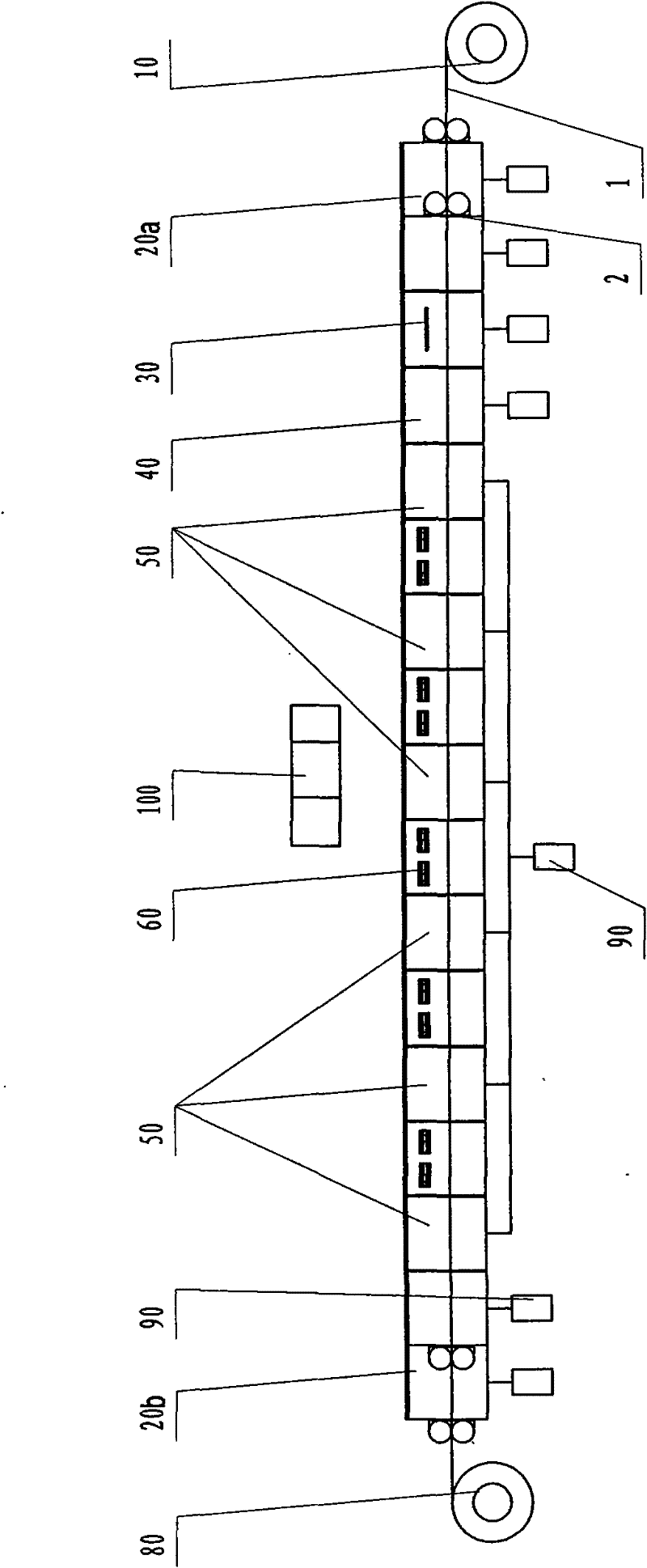

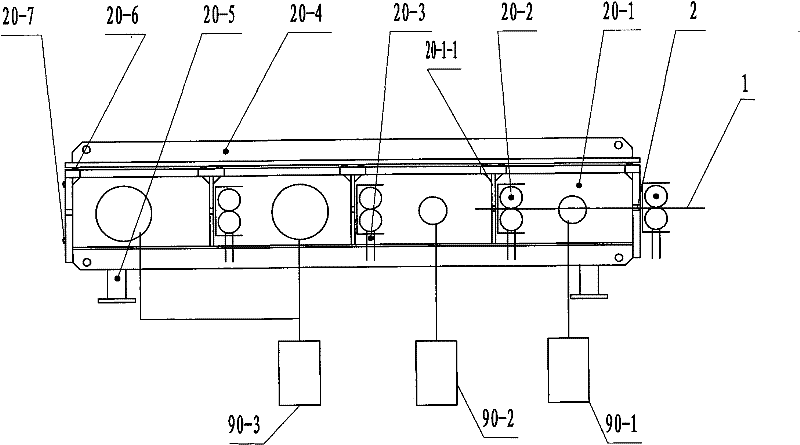

[0029] See figure 1 , a continuous winding coating device for solar energy selective absorption film, comprising uncoiling unit 10, the vacuum coating chamber provided includes A low vacuum chamber 20a, 20b, ion treatment chamber 30, B low vacuum chamber 40, high vacuum chamber 50 , 5 vacuum coating chambers 60, there is a flange sealing connection between the chamber and the chamber, and a window 2 through which the metal sheet band 1 passes; A low vacuum chamber 20a, 20b, ion processing chamber 30, B low vacuum chamber 40, The high vacuum chamber 50 and the vacuum coating chamber 60 are connected with the vacuum unit 90; a winding unit 80 and a continuous coating control system 100 are also arranged outside the vacuum coating chamber.

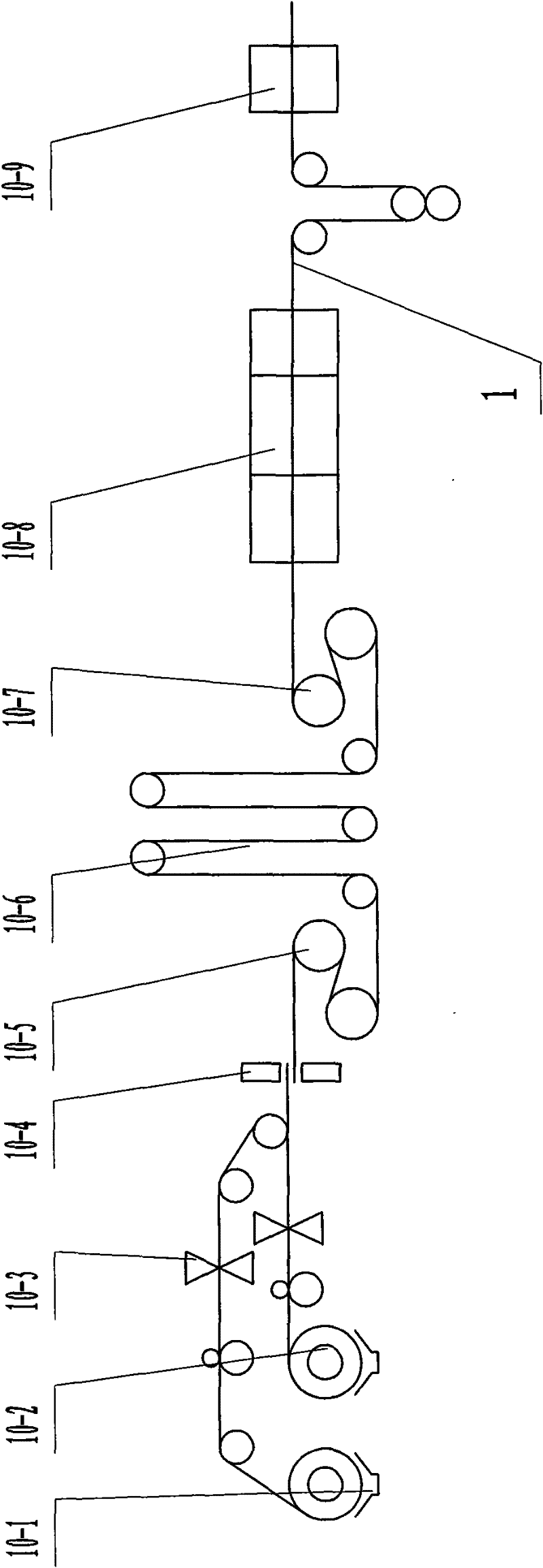

[0030] See figure 2 , the uncoiling unit 10 includes a winding roller 10-1, an uncoiling roller 10-2, and a cutting head 10-3 and a welding 10-4 are arranged in front of the winding roller 10-1 and the uncoiling roller 10-2; Between the 1#...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com