Metal foil and manufacturing method and manufacturing device thereof

A metal foil and equipment technology, applied in the field of metal foil and its preparation, can solve the problems of high energy consumption, bulky volume, and large number of equipment, and achieve the effects of low energy consumption, small volume, and uniform thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

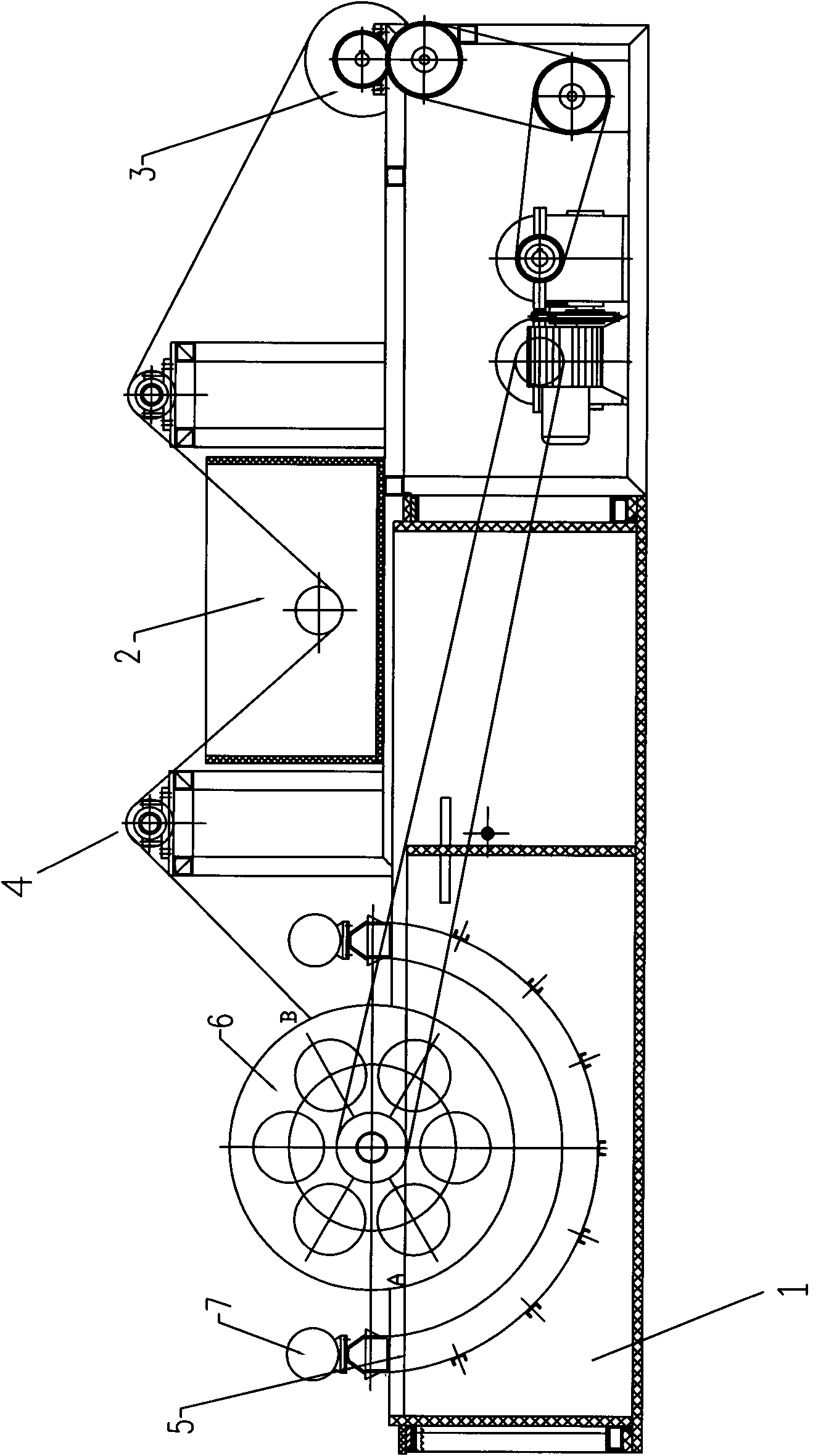

[0046] The accompanying drawing is a specific embodiment of the present invention.

[0047] The metal foil preparation method of the present invention is composed of the following steps in sequence:

[0048] a. Electrodeposition: take the industrial pure metal as the anode and the aqueous solution of the metal sulfamate or sulfate as the plating solution, so that the metal ions are deposited on the continuously rotating cathode roller, and the continuous growth and continuous peeling; electrodeposition in the plating tank By adjusting the current size and the rotation speed of the cathode roller, metal coatings of different thicknesses can be prepared, and by changing the plating solution formula and anode material, metal foils of different materials can be prepared;

[0049] b. Peeling: Using the tension generated by the rotation of the cathode roll and the winding system, the metal coating deposited on the cathode roll is continuously peeled off. Due to the rotation of the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com