Method for preparing immobilized laccase in electrospun fiber membrane

A technology for immobilizing laccase and electrospinning fibers, which is applied in the directions of immobilization on/in organic carriers, fiber processing, textiles and papermaking, etc. problems, to achieve the effects of good stability and reusability, protection of enzyme activity, and high enzyme loading capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0028] The preparation steps of the enzyme-loaded electrospun fiber membrane include:

[0029] 1) Dissolve polylactic acid-caprolactone copolymer (P(LA / CL), 7 / 3) particles with a molecular weight of 100,000 in dichloromethane, add block copolymer surfactant F108, mix evenly and stir Obtain copolymer mixed gel in 2 hours, wherein the consumption of block copolymer F108 is 10% of polylactic acid-caprolactone copolymer (P(LA / CL), 7 / 3) weight;

[0030] 2) Weigh 10 mg of Versicolor versicolor laccase and dissolve it in 1 ml of phosphate buffer solution with a pH value of 3.5, and shake until completely dissolved. In order to observe the distribution of laccase in the electrospun fiber using laser confocal scanning microscope, the concentration of 10 mg / ml of laccase solution;

[0031]3) Add the laccase solution obtained in step 2) into the copolymer mixed gel, and mix on a vortex mixer for 20 minutes until a homogeneous emulsion is formed, wherein the volume ratio of the enzyme ...

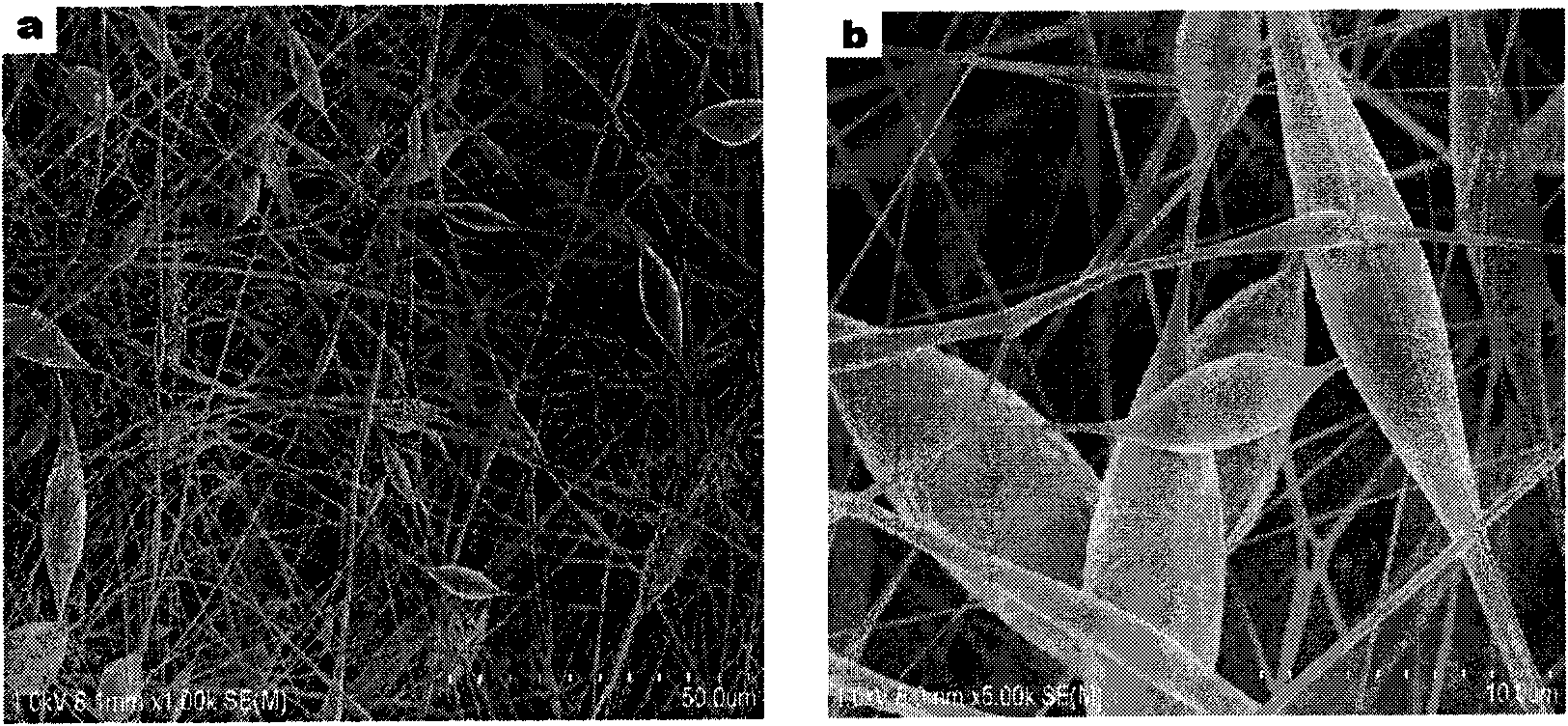

Embodiment 1

[0046] 0.6 g of poly(lactic acid-caprolactone) copolymer (P(LA / CL), 7 / 3) was dissolved in 12 g of dichloromethane, then 0.06 g of block copolymer surfactant F108 was added, mixed evenly and stirred for 2 hours A copolymer mixed gel was obtained. Weigh 10 mg of Versicolor versicolor laccase and dissolve it in 1 ml of phosphate buffered saline solution with a pH value of 3.5, and shake until completely dissolved. Add 0.1 ml of the above laccase solution or 10 mg / ml laccase solution labeled with fluorescein isothiocyanate (FITC) into the copolymer mixed gel, and mix on a vortex mixer for 20 minutes until a homogeneous gel is formed. quality lotion. The emulsion is then introduced into a high-voltage electrospinning device to be spun. Adjust the high-voltage power supply voltage to 10 kV and the receiving distance to 14 cm to obtain a stable and continuous jet stream, and collect the fiber product on the receiving plate covered with aluminum foil. During the whole process of sp...

Embodiment 2

[0049] 0.6 g of poly(lactic acid-caprolactone) copolymer (P(LA / CL), 7 / 3) was dissolved in 12 g of dichloromethane, then 0.06 g of block copolymer surfactant F108 was added, mixed evenly and stirred for 2 hours A copolymer mixed gel was obtained. Weigh 10 mg of Versicolor versicolor laccase and dissolve it in 1 ml of phosphate buffered saline solution with a pH value of 3.5, and shake until completely dissolved. Take 0.15 ml of the above-mentioned laccase solution or a 10 mg / ml laccase solution labeled with fluorescein isothiocyanate (FITC) and add it to the copolymer mixed gel, and mix on a vortex mixer for 20 minutes until a homogeneous gel is formed. quality lotion. The emulsion is then introduced into a high-voltage electrospinning device to be spun. Adjust the voltage of the high-voltage power supply to 11 kV, and the receiving distance is 14 cm to obtain a stable and continuous jet stream, and collect the fiber product on the receiving plate covered with aluminum foil. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com