Silver-coated material for movable contact component and method for manufacturing such silver-coated material

A technology of silver coating and moving contact, which is applied in the direction of contact manufacturing, contact parts, contact materials, etc., and can solve problems such as silver peeling and heating of the switch part

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

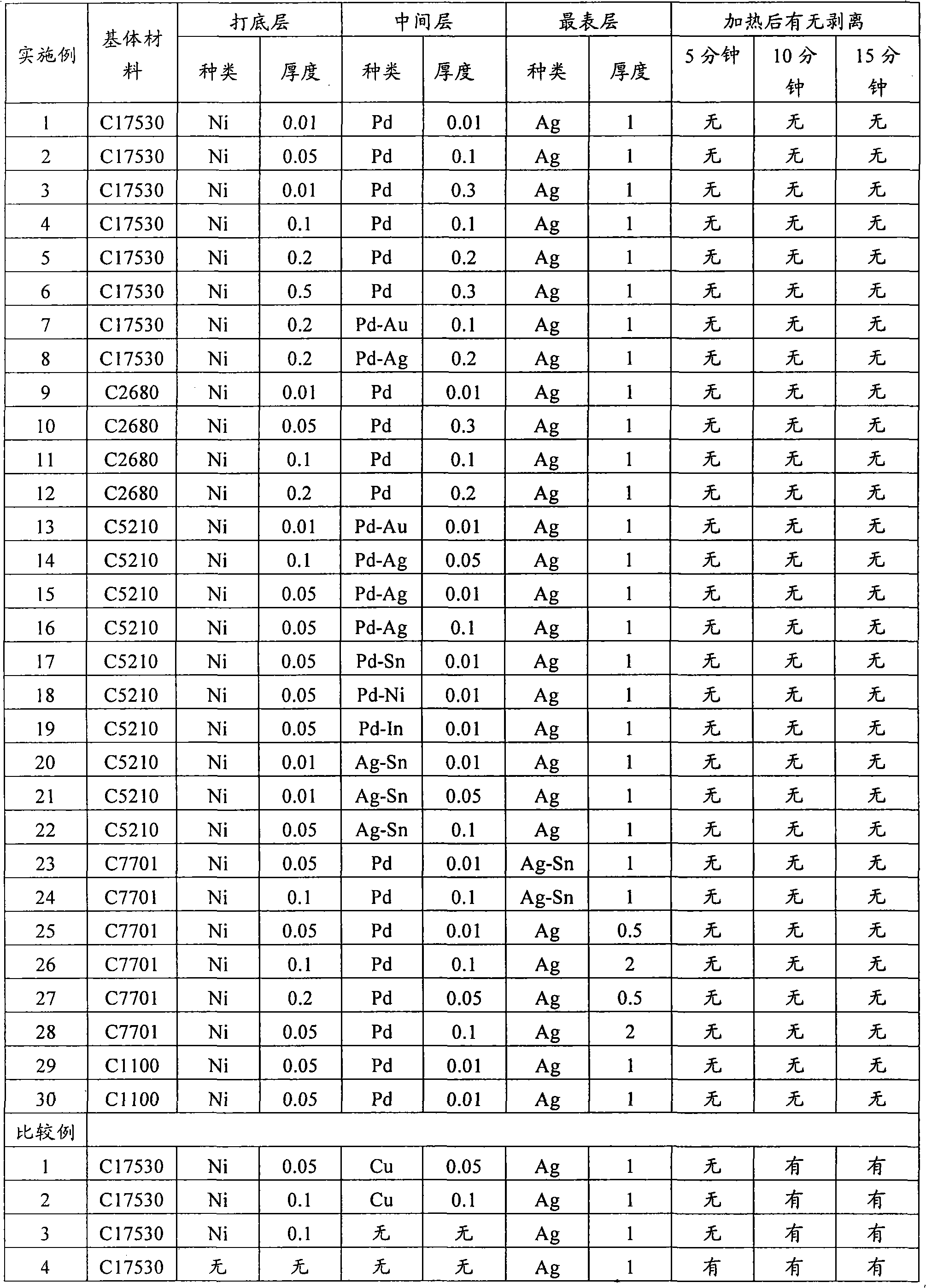

Embodiment 1~8

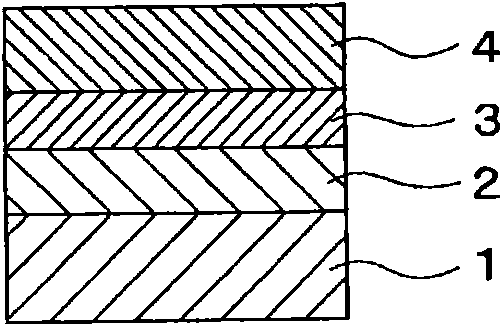

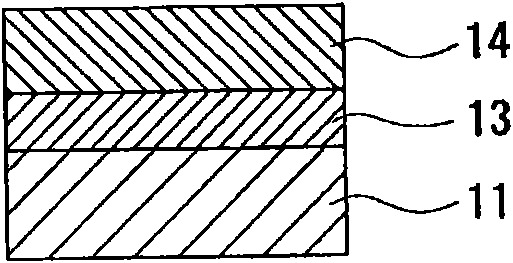

[0045] A plate material of beryllium copper (Be—Cu: C17530) having a thickness of 0.25 mm and a plate width of 100 mm was subjected to the following treatment to obtain a silver-coated material having a layer structure shown in Table 1.

[0046] (1) Pretreatment: immerse in a mixture of 4% sulfuric acid and 200g / l sodium dichromate for 1 to 3 minutes at room temperature, and then perform cathodic degreasing (50°C, 2A / dm 2 ).

[0047] (2) Nickel primer plating: use a plating solution containing 5g / l nickel chloride and 30% free hydrochloric acid, at a cathode current density of 2A / dm 2 Carry out under certain conditions to form a bottom layer.

[0048] (3) Activation treatment: The Cu-Be strips plated with the nickel primer layer are kept in warm to hot water at 40 to 90° C. for 3 seconds or more. The temperature of the Be-Cu strip from electrolytic degreasing to the activation treatment was controlled by immersing the Be-Cu strip in a water washing tank whose temperature was...

Embodiment 9~30

[0055] Brass (Cu-Zn: C2680), phosphor bronze (C5210: Cu-Sn-P), copper-nickel-zinc alloy (Cu-Ni-Zn: C7701), refined copper (pure copper) with a thickness of 0.25 mm and a plate width of 100 mm System: C1100) plate, degreasing (immersion in 60g / l NaOH solution for 30 seconds) and pickling (immersion in 10% sulfuric acid for 30 seconds), and then carry out (2) in Examples 1-8 ~(7) treatment, the silver-coated material with the layer structure shown in Table 1 was obtained. In addition, the difference from Examples 1 to 8 is that in addition to the above-mentioned (4) or (5) plating, the intermediate layer plating is also subjected to plating selected from the following (8) and (9). In addition, after the plating in (6) is performed on the outermost layer, plating corresponding to the type shown in (7) or the following (9) is also performed.

[0056] (8) Intermediate layer (Pd-Sn, Pd-Ni, Pd-In) plating: Plating using various metal salts containing 100g / l palladium sulfate, 30g / l ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com