Method for comprehensively utilizing polysilicon by-product with low cost

A technology for by-products and polycrystalline silicon, which is applied in the field of low-cost comprehensive utilization of polycrystalline silicon by-products, can solve the problems of difficult recycling of hydrolyzed products, difficult to uniformly disperse the amount of alkali, and acidic or alkaline products, etc. The effect of low requirements and high utilization value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

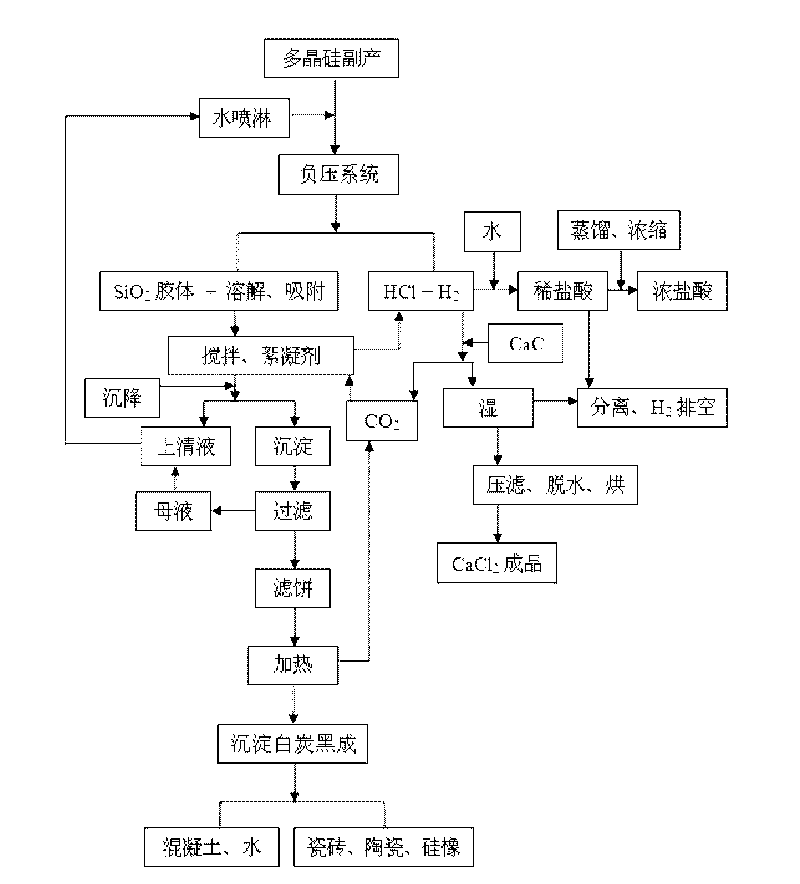

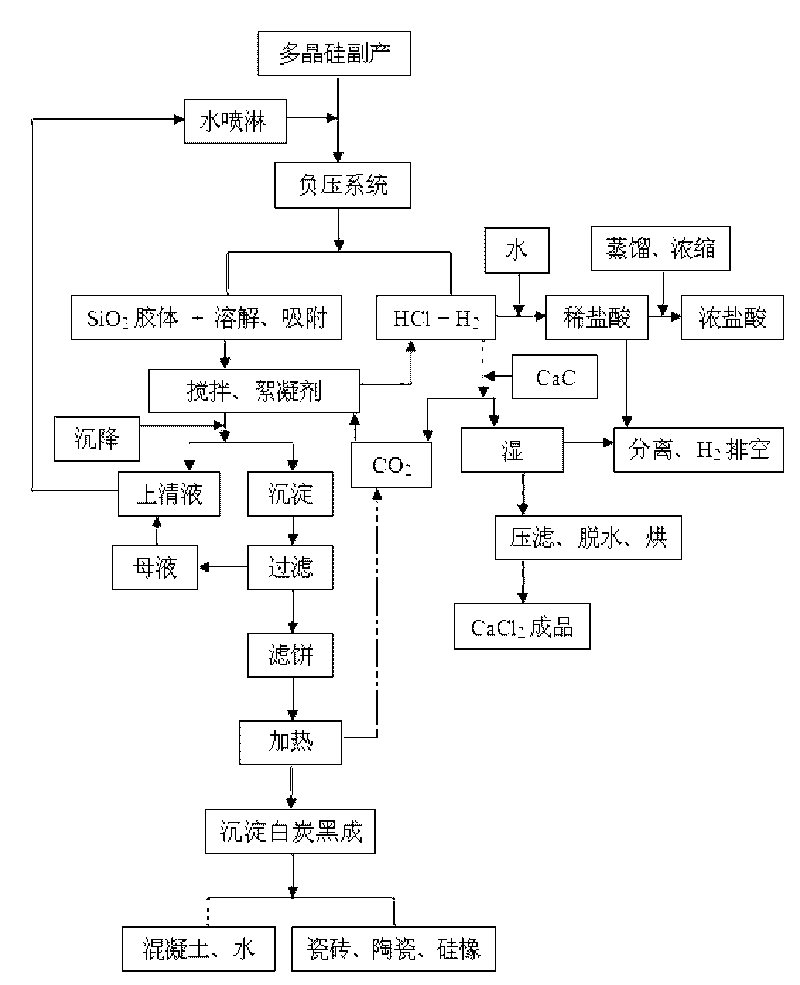

Image

Examples

Embodiment 1

[0050] In a closed reactor, polysilicon by-products and enhanced medium CO 2 Pressed in from the bottom of the reactor, water reacts with by-products in a spraying manner from the top of the reactor, the molar ratio of polysilicon by-products to river water is n 多晶硅副产物 : n 水 =1:3.5.

[0051] The upper part of the reaction kettle uses an acid-resistant vacuum pump to reduce the pressure in the reaction kettle by 0.1 atmosphere, so that the pressure in the kettle reaches 0.9 atmosphere, and the extracted gas is absorbed by water to form hydrochloric acid or react with limestone to form calcium chloride, and the rest of the gas is separated and emptied .

[0052] Add flocculant (polyacrylamide) to the silica colloid in the tank under stirring to form a precipitate, filter after sedimentation, mix the mother liquor with the supernatant and use it as a raw material for polysilicon by-product hydrolysis reaction, and filter cake silica Roasting at 500°C removes the flocculant, an...

Embodiment 2

[0055] In a closed reactor, polysilicon by-products and enhanced medium CO 2 Pressed in from the bottom of the reactor, water reacts with by-products in a spraying manner from the top of the reactor, the molar ratio of polysilicon by-products to river water is n 多晶硅副产物 : n 水 =1:5.

[0056] The upper part of the reaction kettle uses an acid-resistant vacuum pump to reduce the pressure in the reaction kettle by 0.5 atmospheres, so that the pressure in the kettle reaches 0.5 atmospheres, and the extracted gas is absorbed by water or reacted with other reaction media and then separated and emptied.

[0057] Add flocculant (polyacrylic acid) to precipitate the silica colloid in the tank under the stirring action. After filtering, mix the mother liquor with the supernatant and use it as the raw material for polysilicon by-product reaction. The filter cake silica is roasted at 700°C The flocculant is removed, while the generated CO 2 Returning to the reactor for recycling, it play...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com