Decoloration technology of biological diesel oil

A biodiesel and decolorization technology, which is applied in the fields of biofuel, petroleum industry, and fat production, can solve the problems of high toxicity, increased equipment and operating costs, and no quantification of decolorization indicators, and achieves high recovery efficiency, high methyl ester content, No effect of waste water pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Embodiment 1, the biodiesel decolorization that dark vegetable oil enzyme catalysis method prepares

[0025] The specific method includes the following steps:

[0026] (1) get 20) 0) g dark crude methyl ester (or thick ethyl ester) that the enzymatic method that obtains makes and add 10g of activated clay and bentonite mixture, activated clay quality is 40% in activated clay and bentonite mixture, the rest For bentonite, the temperature is controlled at 125°C, and the reaction is stirred for 30 minutes.

[0027] (2) Stand still for 1h to separate the phases.

[0028] (3) Take 100 g of the obtained above-mentioned methyl ester (or crude ethyl ester) after adsorption and decolorization, add 6 g of hydrogen peroxide, and stir the reaction for 30 minutes at a temperature of 87° C.

[0029] (3) Centrifuge at 4800rpm for 10 minutes to separate the phases.

[0030] The product obtained above was added to a 1.0 cm cuvette, and the absorption spectrum was scanned at 465 nm to...

Embodiment 2-4

[0034] Embodiment 2-4, change the decolorization purification of the biodiesel that dark vegetable oil production method obtains

[0035]In the same decolorization method as in Example 1, the amount of dark diesel oil processed by activated clay and bentonite and the amount of diesel oil processed by hydrogen peroxide were 200g and 100g respectively. Among them, the dark biodiesel comes from the acid method, the alkali method and the supercritical method respectively, and the amount of the decolorizing agent is changed to obtain purified biodiesel with a decolorization rate above 82%. See Table 2 for the results.

[0036] Table 2 Example 2-4 results

[0037] Variation factor

Embodiment 5-9

[0038] Example 5-9, decolorization of biodiesel prepared from different dark oil raw materials

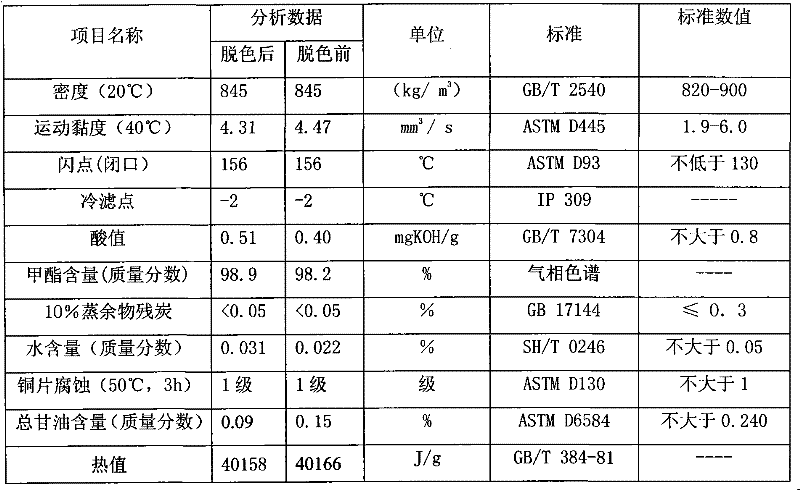

[0039] Use the method of the present invention to carry out the production, decolorization and purification of biodiesel, the specific method is the same as in Example 1, the difference is that the raw material for producing crude methyl ester is changed, and the important indicators of purified biodiesel are shown in Table 3

[0040] Table 3 Example 5-9 Results

[0041] project name

PUM

| Property | Measurement | Unit |

|---|---|---|

| absorbance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com