Method for extracting active ingredients in garlic straw by biological enzyme hydrolysis

A technology of garlic stalks and active ingredients, which is applied in the field of biological enzyme hydrolysis to extract active ingredients of garlic stalks, can solve the problem of high cost, achieve the effects of improving efficacy, avoiding environmental pollution, and reducing manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

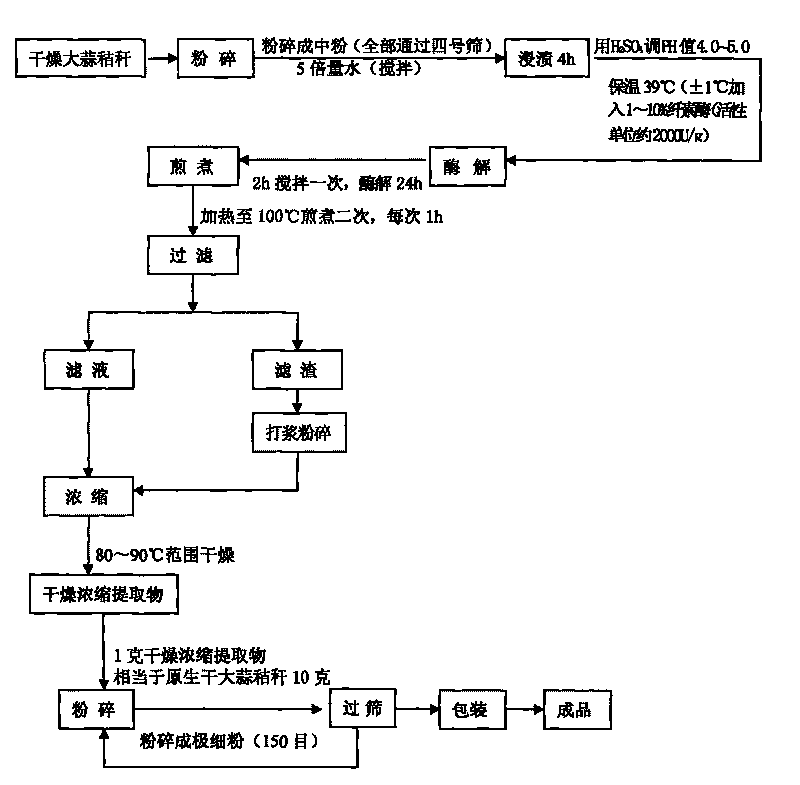

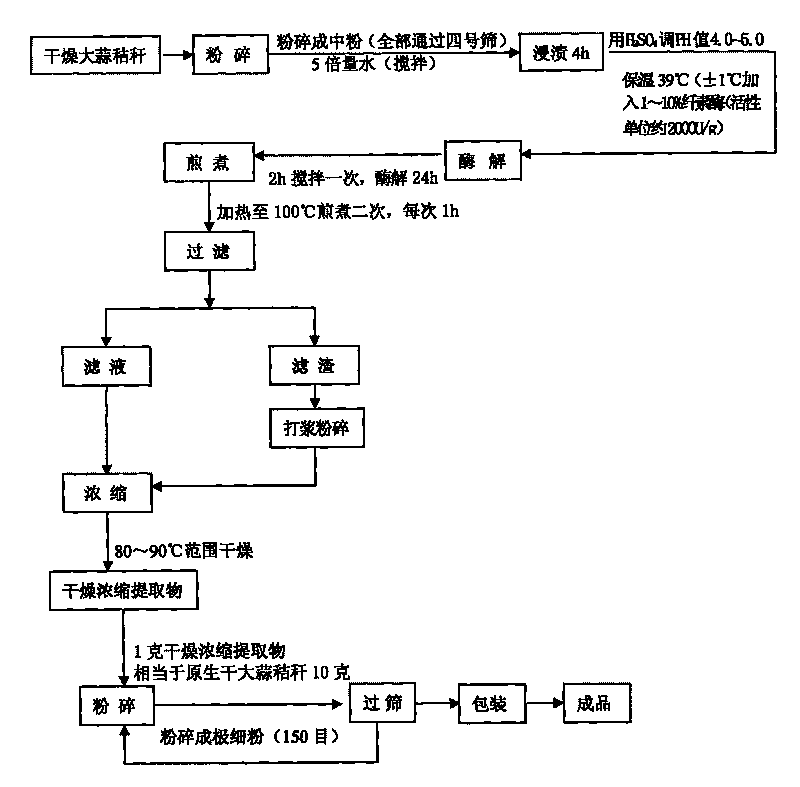

[0011] Grind the dry and clean garlic stalks into medium powder, add 5 times the amount of water and stir to make the impregnation evenly, impregnate for about 4 hours to ensure the impregnation, adjust the pH value to 4.0-5.0 with sulfuric acid, add 1-10% cellulase (the activity unit is about 2000U / g) and fully stirred, the constant temperature is in the range of 39°C (±1°C), enzymatic hydrolysis for 24h, stirring once every 2h. After enzymolysis, heat to inactivate the enzyme, and add to 100°C and continue to decoct twice, each time decocting for 1 hour, filter while hot, save the filtrate, beat the filter residue with a beater and combine it with the filtrate in a jacketed pot Further condense into a thick paste, dry in the range of 80-90°C to obtain 1 gram of dried concentrated extract equivalent to 10 grams of original dried garlic stalks, and grind the dried enzymatic extract into a very fine powder (150 mesh ), sieve and package the finished product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com