Method for processing steel mold cavity

A processing method and model technology, applied in the direction of metal processing equipment, electrochemical processing equipment, manufacturing tools, etc., can solve the problems of slow EDM processing speed, difficult to ensure processing accuracy, loss of tool electrodes, etc., to achieve low cost, The effect of high production efficiency and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

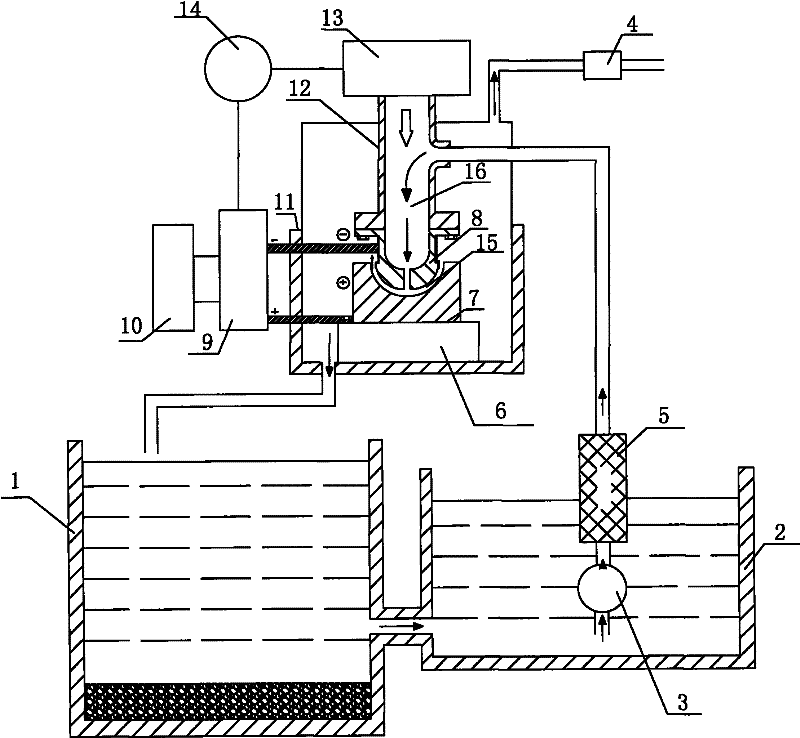

[0033] The present invention will be described in detail below in conjunction with the accompanying drawings, but the present invention is not limited to this embodiment.

[0034] Taking the processing of the instrument panel stamping die in the aircraft operating room as an example, the processing steps are as follows:

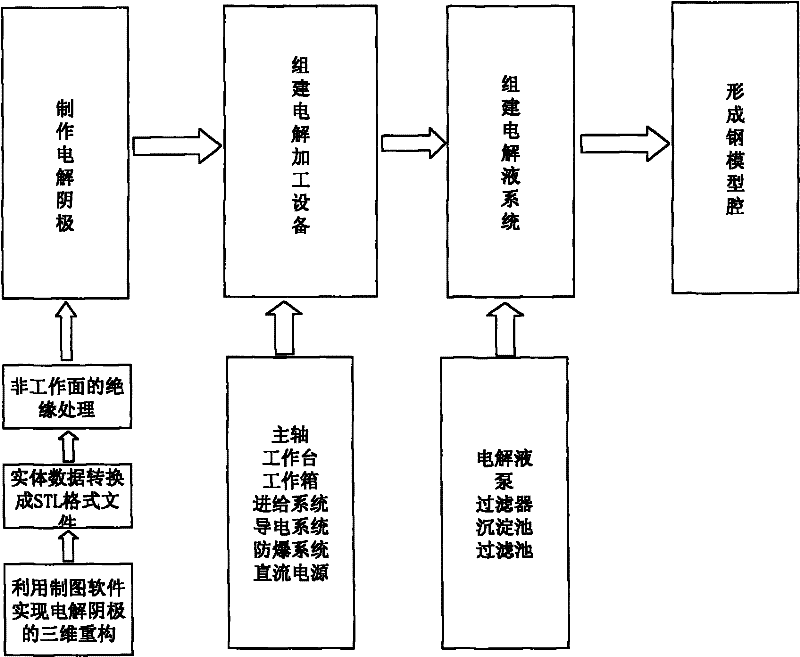

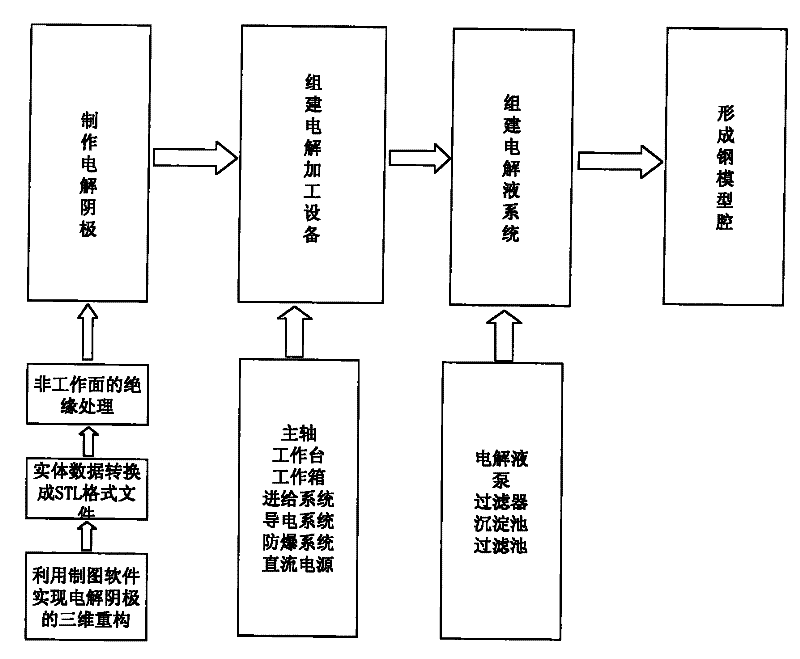

[0035] 1) Make electrolytic cathode

[0036] a. Using CAD drawing software to realize the three-dimensional graphic reconstruction of the electrolytic cathode;

[0037] b. The entity data reconstructed with the above three-dimensional graphics is converted into an STL format file, and after layered and sliced processing by Rpdata software, the default format file of the selective laser sintering molding equipment is generated, which is input into the selective laser sintering molding equipment to prepare electrolytic cathode;

[0038] C, the prepared electrolytic cathode is carried out to the non-working surface of the porcelain firing process;

[0039] ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap