Halogen-free lead-free soldering paste for radiator and preparation method thereof

A lead-free solder and heat sink technology, applied in welding equipment, welding medium, manufacturing tools, etc., can solve problems affecting the expansion rate and oxidation resistance of solder paste, hidden dangers of product reliability, and insulation resistance reduction, etc., and achieve high strength Oxidation resistance, good viscosity, low corrosion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

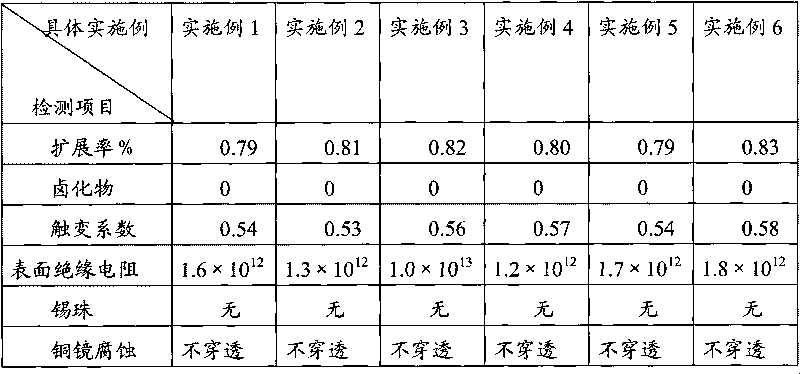

Examples

Embodiment 1

[0032] Flux raw materials: polymerized rosin 50g, hydrogenated rosin 5g, suberic acid 2g, glutaric acid 2g, triethanolamine 2g, hydrogenated castor oil 3g, benzotriazole 1g, nonyl polyoxyethylene ether 1g, ethylene glycol benzene Ether 34g.

[0033] Preparation method: mix 2g of suberic acid, 2g of glutaric acid, 2g of triethanolamine and 10g of ethylene glycol phenyl ether, and heat until completely dissolved to prepare an organic acid and organic amine composition, and cool to room temperature for later use. Mix 50g of polymerized rosin, 5g of hydrogenated rosin and 24g of ethylene glycol phenyl ether, heat and dissolve completely, add 3g of hydrogenated castor oil and 1g of benzotriazole, completely dissolve and cool to room temperature, then add nonyl poly 1g of oxyethylene ether and 16g of the composition of organic acid and organic amine, stir evenly to make flux, and place it in an environment with a temperature of 5-12°C. After 24 hours, take 15g of flux and 85g of Sn4...

Embodiment 2

[0035] Flux raw materials: polymerized rosin 45g, hydrogenated rosin 5g, suberic acid 6g, triethanolamine 2g, salicylamide 1g, ethylene bis stearic acid amide 1g, hydrogenated castor oil 4g, benzotriazole 1g, nonyl Polyoxyethylene ether 1.5g, ethylene glycol monobutyl ether 33.5g.

[0036] Preparation method: mix 6 g of suberic acid, 2 g of triethanolamine, 1 g of salicylic amide and 10 g of ethylene glycol monobutyl ether, and heat until completely dissolved to prepare an organic acid and organic amine composition, and cool to room temperature for later use. Mix 45g of polymerized rosin, 5g of hydrogenated rosin and 23.5g of ethylene glycol monobutyl ether, heat and dissolve completely, add 4g of hydrogenated castor oil, 1g of ethylene bis-stearamide, 6g of suberic acid, and 2g of triethanolamine , 1g of benzotriazole, completely dissolved and cooled to room temperature, then added 1.5g of nonyl polyoxyethylene ether, 19g of organic acid and organic amine composition, stirred...

Embodiment 3

[0038] Flux raw materials: polymerized rosin 35g, hydrogenated rosin 10g, suberic acid 4g, glutaric acid 2g, succinic anhydride 2g, triethanolamine 1g, salicylamide 3g, ethylene bis-stearamide 4g, hydrogenated castor oil 2g , 1.5 g of benzotriazole, 1.5 g of nonyl polyoxyethylene ether, 15 g of ethylene glycol phenyl ether, and 19 g of ethylene glycol monobutyl ether.

[0039] Preparation method: mix 4g of suberic acid, 2g of glutaric acid, 2g of succinic anhydride, 3g of triethanolamine, 3g of salicylamide and 10g of ethylene glycol phenyl ether, and heat until completely dissolved to make organic acid and organic Amine composition, cooled to room temperature for later use. Mix 35g of polymerized rosin, 10g of hydrogenated rosin, 5g of ethylene glycol phenyl ether, and 9g of ethylene glycol monobutyl ether, heat and dissolve completely, add 2g of hydrogenated castor oil, 4g of ethylene bis stearic acid amide, benzo After 1.5g of triazole is completely dissolved and cooled to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com