Atractylone lipidosome and preparation method thereof

The technology of Atractylodes ketone lipid and Atractylodes ketone is applied in the field of Atractylodes ketone liposome and its preparation, which can solve the problems of small intermolecular force, large particle size of liposome, easy agglomeration and the like, and achieves uniform distribution, small particle size, Overcome the effect of easy agglomeration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] Preparation and determination of embodiment 1 atractylone liposome

[0048] 1. Preparation of atractylone liposomes

[0049] Materials and devices: Atractylone, the extract of Atractylodes macrocephala koedz, provided by Neptunus Biological Co., Ltd., with a mass fraction ≥ 95%, batch number 080115; the medicinal material is produced in Pan'an, Zhejiang, provided by Zhejiang Pan'an Medicinal Materials Company, Batch number BZ07061501; phosphatidylcholine and cholesterol, provided by Shanghai Boao Bioengineering Co., Ltd., analytically pure, batch number BA20071206, BA20071125; supercritical fluid reaction experimental device, designed and manufactured by the Modern Technology Center of South China University of Technology.

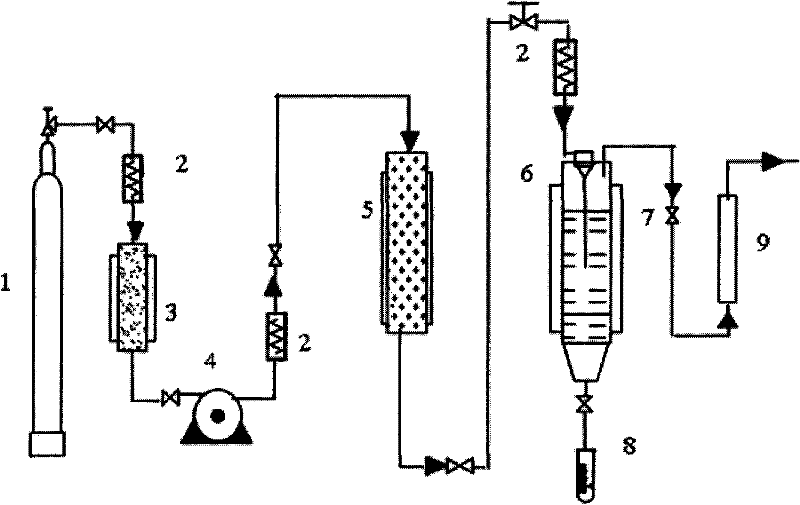

[0050] Preparation method: In one embodiment, the method for preparing atractylone liposomes of the present invention can be carried out under supercritical CO 2 Completed in the rapid expansion device, the detailed flow chart is as follows figu...

Embodiment 2

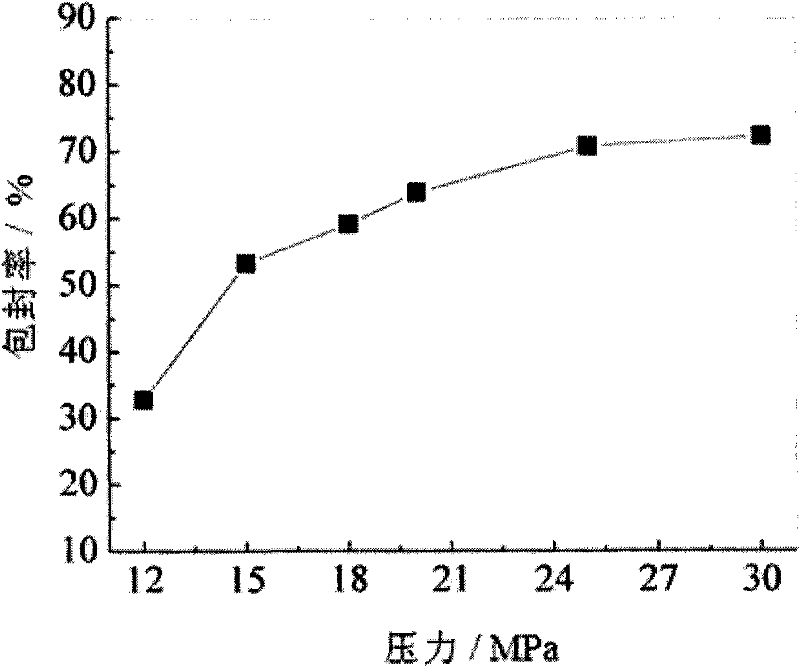

[0062] The influence of embodiment 2 pre-expansion pressure on the preparation of atractylone liposome

[0063] This example investigates the effect of pre-expansion pressure on the preparation of atractylone liposomes. Using the same method as in Example 1, after dissolving atractylone and liposome membrane material in the supercritical fluid according to the ratio of Example 1, the temperature is 333K, and the co-solvent ethanol is in CO 2 Middle mole fraction x(CH 3 CH 2 OH)=15%, in 15~30MPa condition pre-expansion, spray in the buffer solution that does not contain stabilizer, measure the encapsulation efficiency of preparing liposome under different pressures, the result is as follows figure 2 shown.

[0064] The experimental results showed that under lower pressure, liposome membrane materials phospholipids and cholesterol were in SC-CO 2 The solubility is small, and it is difficult to form a uniform liposome membrane. There are a large number of phospholipid bloc...

Embodiment 3

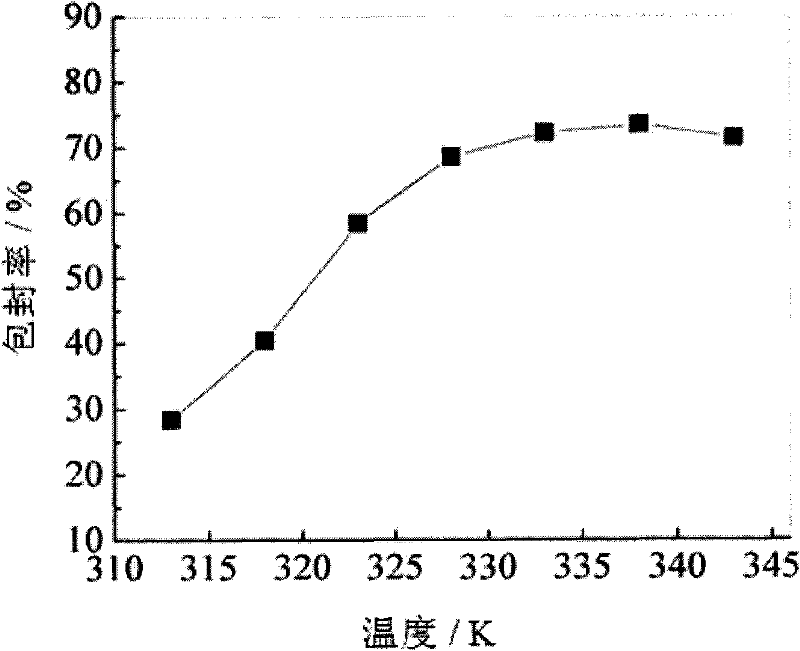

[0065] The influence of embodiment 3 pre-expansion temperature on the preparation of atractylone liposome

[0066]This example investigates the effect of pre-expansion temperature on the preparation of atractylone liposomes. Adopt the method identical with embodiment 1, atractylone and liposome membrane material are dissolved in the supercritical fluid after the ratio of embodiment 1, under pressure is 30MPa, x (CH 3 CH 2 OH)=15% condition, pre-expansion under 313K~343K, spray in the buffer solution that does not contain stabilizer, measure the encapsulation efficiency of liposome preparation in different temperature ranges, the result is as follows image 3 shown.

[0067] The experimental results show that the physical properties of liposomes are closely related to the preparation temperature. When the temperature is lower than 323K, which is lower than the phase transition temperature Tm of phospholipids, SC-CO 2 The phospholipid bilayers formed in the liposomes are c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com