Method for preparing fluorine-containing electronic ink microcapsule

A technology of electronic ink and microcapsules, which is applied in the field of preparation of fluorine-containing electronic ink microcapsules, can solve the problems of difficulty in using flexible electrophoretic display devices, poor flexibility, pressure resistance, and affecting the performance of microcapsules, so as to improve storage and work. The effects of stability, low cost, and high heat stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Carboxymethylcellulose sodium is made into 100 grams of an aqueous solution with a mass ratio concentration of 0.5%, and perfluorononenyloxybenzenesulfonate is made into 6.48 grams of an aqueous solution with a mass ratio concentration of 1%, and they are all kept at 80°C. Standby; the gelatin is made into 50 grams of an aqueous solution with a mass ratio concentration of 10%, and it is kept warm at 60° C. for standby use.

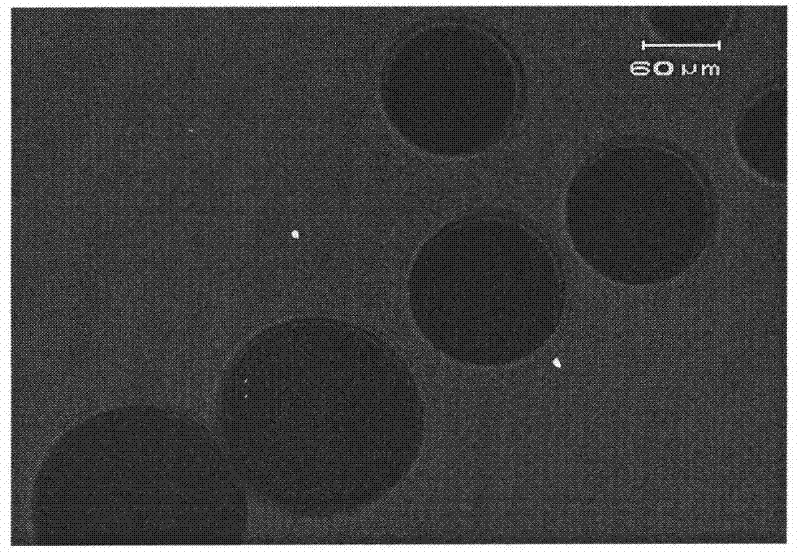

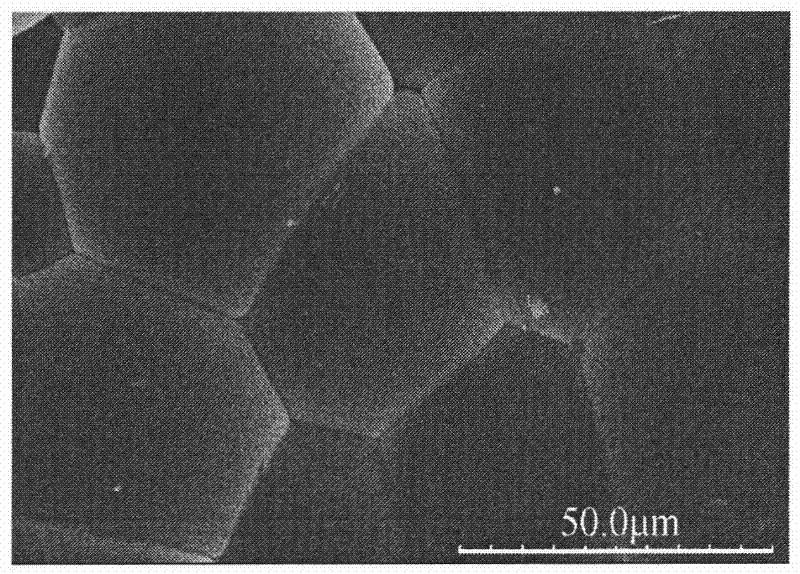

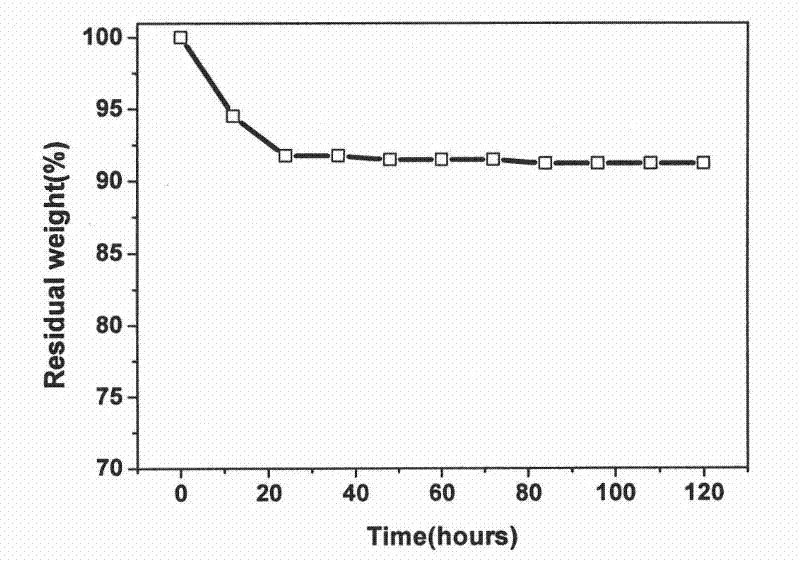

[0023] Add electrophoretic particles, dyes, and additives to tetrachlorethylene, ultrasonically shake at 45°C to make 28 grams of a uniformly dispersed electrophoretic suspension, add to the above-mentioned gelatin / sodium carboxymethylcellulose / perfluorononene In the aqueous solution of sodium benzenesulfonate, disperse at a stirring rate of 500rpm for 30 minutes to obtain an O / W emulsion. At 45°C, use 20% acetic acid solution to reduce the pH value of the system to 4.5, and slowly lower the temperature to 15°C, add 10.0 ml of 15% glutaraldehyde aqu...

Embodiment 2

[0025] Sodium carboxymethyl cellulose is made into 640 grams of the aqueous solution whose mass ratio concentration is 1%, and perfluorooctanoic acid potassium is made into 64 grams of the aqueous solution whose mass ratio concentration is 0.1%, all keep warm at 70 ℃ for standby; Gelatin is made into 32 The gram mass ratio concentration is the aqueous solution of 10%, and it is standby to keep warm at 60 ℃.

[0026] Add electrophoretic particles, dyes, and additives to tetrachloroethylene, ultrasonically vibrate at 45°C to make 30 grams of a uniformly dispersed electrophoretic suspension, and add it to the above-mentioned gelatin / sodium carboxymethylcellulose / potassium perfluorooctanoate solution, Disperse at a stirring rate of 350rpm for 30 minutes to prepare an O / W emulsion. Use 10% citric acid solution at 45°C to lower the pH value of the system to 4.5, slowly lower the temperature to 5°C while stirring, and dissolve 6.0ml of 25 % of succinic dialdehyde aqueous solution is ...

Embodiment 3

[0028] Carboxymethylcellulose sodium is made into 100 grams of an aqueous solution with a mass ratio concentration of 10%, and perfluorooctanoic acid sodium is made into 100 grams of an aqueous solution with a mass ratio concentration of 10%, which are all kept at 90°C for standby; An aqueous solution with a mass ratio concentration of 5%, and keep warm at 45°C for use.

[0029] Add electrophoretic particles, dyes, and additives to tetrachloroethylene, ultrasonically vibrate at 45°C to make 25 grams of a uniformly dispersed electrophoretic suspension, and add it to the above-mentioned gelatin / sodium carboxymethylcellulose / sodium perfluorooctanoate solution, Disperse at a stirring rate of 500rpm for 100 minutes to prepare an O / W emulsion. Use 0.05% sulfuric acid solution at 45°C to lower the pH value of the system to 4.5, slowly lower the temperature to 0°C while stirring, and add 5.0ml of 37% The aqueous solution of acetaldehyde was added dropwise to the above system to solidi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com