Application of alkaline electrolyte membrane in alkaline direct alcohol fuel cell

An electrolyte membrane and fuel cell technology, which is applied to fuel cell components, fuel cells, circuits, etc., can solve the problems of poor alkali resistance and high temperature resistance, achieve good alkali resistance and high temperature resistance, good commercial sources, and improve electrodes The effect of kinetically slow processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

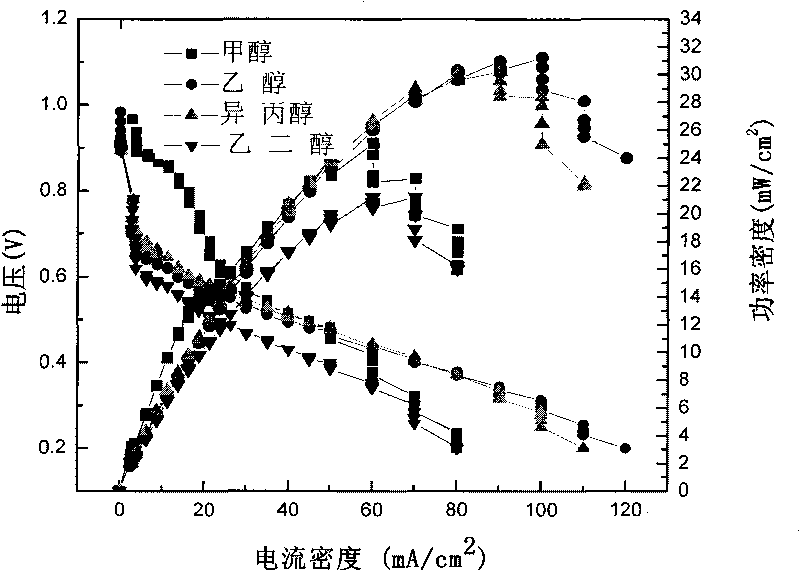

[0028] PtRu / C with 45% active component by weight is used as the anode catalyst, carbon paper is used as the support layer of the gas diffusion layer, and the loading capacity of the noble metal is 2.0 mg / cm 2 ; The cathode catalyst is 40% Pt / C by weight of the active component, with carbon paper as the support layer of the gas diffusion layer, and the precious metal loading is 1.0mg / cm 2 ;The Nafion115 membrane immersed in 6M KOH solution at room temperature for 2 days is used as the alkaline electrolyte membrane and sandwiched between two gas diffusion electrodes, and then a metal mesh is placed on the outside of the electrodes as a current collector, and polytetrafluoroethylene is used as a sealing material , and finally clamped with a metal plate with a point-like flow field, and fixed with screws. Mixed solutions of 2M methanol + 2M KOH, 2M ethanol + 2M KOH, 2M isopropanol + 2M KOH, ethylene glycol + 2M KOH were fed into the anode side, and pure oxygen was fed into the ca...

Embodiment 2

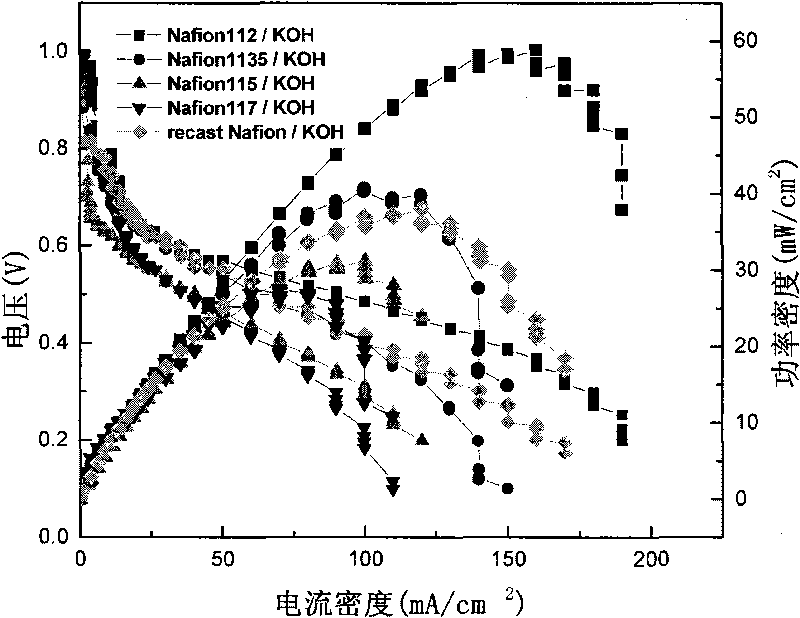

[0030] 45% PtRu / C by weight of the active component is used as the anode catalyst, carbon paper is used as the support layer of the gas diffusion layer, and the loading amount of the precious metal is 2.0 mg / cm 2 ; The cathode catalyst is 40% Pt / C by weight of the active component, with carbon paper as the support layer of the gas diffusion layer, and the precious metal loading is 1.0mg / cm 2 ; Nafion112, Nafion1135, Nafion115, Nafion117, and recast Nafion115 membranes immersed in 6M KOH solution at room temperature for 20 days were respectively used as alkaline electrolyte membranes and sandwiched between two gas diffusion electrodes, and then a metal mesh was placed on the outside of the electrodes as a collector. fluid, and use polytetrafluoroethylene as the sealing material, and finally clamp it with a metal plate with a dotted flow field and fix it with screws. A mixed solution of 2M ethanol + 2M KOH is fed into the anode side, and pure oxygen is fed into the cathode side ...

Embodiment 3

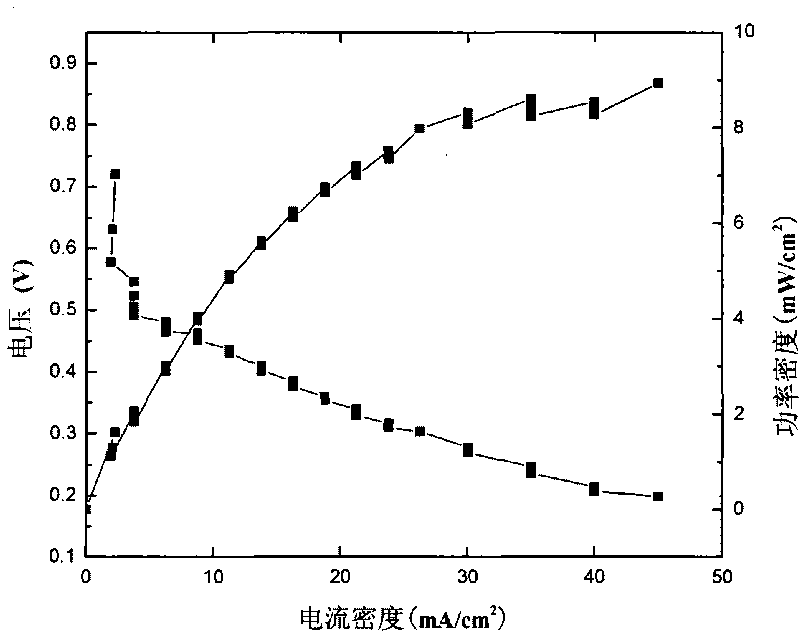

[0032] 45% Pd / C by weight of the active component is used as the anode catalyst, carbon paper is used as the support layer of the gas diffusion layer, and the loading amount of the precious metal is 2.0 mg / cm 2 ; The cathode catalyst is 40% Pt / C by weight of the active component, with carbon paper as the support layer of the gas diffusion layer, and the precious metal loading is 1.0mg / cm 2 ; Nafion112 soaked in 6MKOH solution at room temperature for 30 days as the alkaline electrolyte membrane is sandwiched between two gas diffusion electrodes, and then a metal mesh is placed on the outside of the electrodes as a current collector, and polytetrafluoroethylene is used as a sealing material, and finally It is clamped with a metal plate with a point flow field and fixed with screws. A mixed solution of 2M ethanol + 2M KOH is fed into the anode side, and pure oxygen is fed into the cathode side with a pressure of 0.2MPa. The operating temperature of the battery is 30°C. Single c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com