Ruminant rumen-protected lysine and production method thereof

A ruminant and lysine technology, which is applied in the direction of drug combination, pharmaceutical formula, medical preparations of non-active ingredients, etc., can solve the problems that cannot be realized, fail to meet the requirements of rumen protection, affect the rumen effect, etc., and achieve Reduce the cost of raw materials, improve the coating effect, and have a good rumen passing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

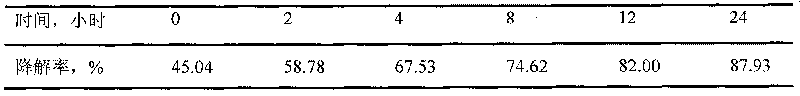

[0027] Example 1 Rumen protected lysine 1

[0028] (1) Preparation of rumen protected lysine

[0029] ① Preparation of lysine granules

[0030] After mixing 480g of lysine hydrochloride, 60g of starch and 60g of microcrystalline cellulose, add appropriate amount of water to adjust to a state that can be granulated, prepare lysine granules with a diameter of 0.5mm with a granulator, and then use a spherical thrower to Shot blasting machine to get lysine pellets.

[0031] ②Drying of lysine granules

[0032] Put the lysine granules prepared in step ① into a fluidized granulation coating machine for drying. The heating temperature of the equipment is 85°C, the frequency of induced wind is 35Hz, the rotation speed is 45Hz, and the drying time is 30 minutes. Then sieve with 30-mesh and 40-mesh sieves respectively to obtain dry lysine granules of 0.40-0.60mm directly under the 30-mesh sieve and above the 40-mesh sieve.

[0033] ③ Coating of lysine particles

[0034] Melt 400g o...

example 2

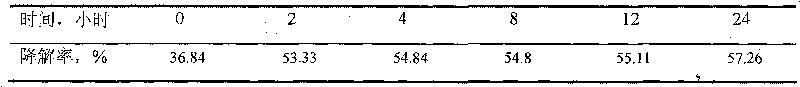

[0040] Example 2: Rumen protected lysine 2

[0041] (1) Preparation of rumen protected lysine

[0042] ① Preparation of lysine granules

[0043] Mix 400g of lysine hydrochloride, 50g of starch and 50g of microcrystalline cellulose, add water to make it ready for granulation, prepare lysine granules with a diameter of 0.5mm with a granulator, and then use a spherical shot blasting machine to prepare lysine granules with a diameter of 0.5mm. Shot blasting to get lysine particles.

[0044] ②Drying of lysine granules

[0045] Put the lysine granules prepared in step ① into a fluidized granulation coating machine for drying. The heating temperature range of the equipment is 85°C, the induced air frequency is 35Hz, the rotation speed is 45Hz, and the drying time is 30 minutes. Then sieve with 30-mesh and 40-mesh sieves respectively to obtain dry lysine particles with a diameter of 0.40-0.60 mm under the 30-mesh sieve and above the 40-mesh sieve.

[0046] ③ Coating of lysine par...

example 3

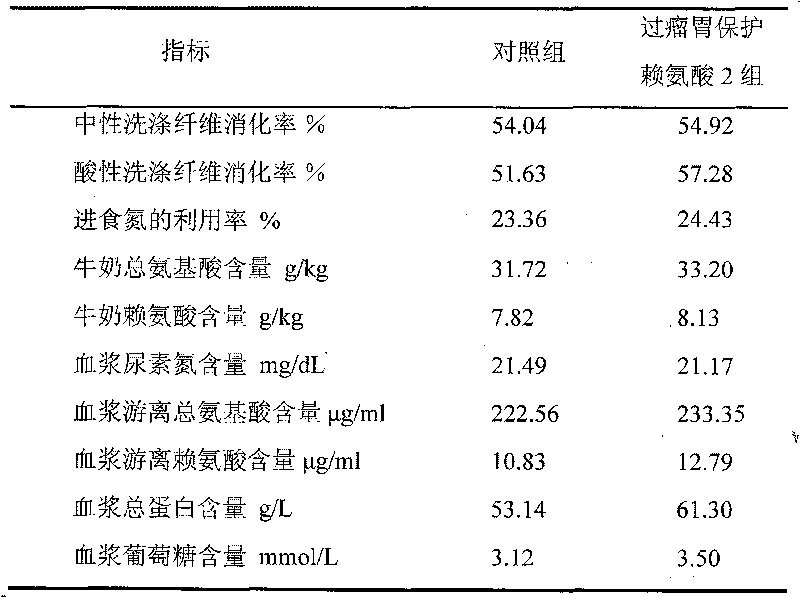

[0054] Example 3 Evaluation of the bioavailability of rumen-protected lysine to lactating cows

[0055] In order to evaluate the bioavailability of the rumen-protected lysine products produced by the above method, three Holstein lactating cows with permanent rumen fistula were used as experimental animals, and the metabolic test was carried out by using a 3×3 Latin square design. Add the rumen-protected lysine 2 product (60 grams / head day) that adds the rumen-protected lysine 2 products (60 grams / head day) that the method of embodiment of the present invention 2 is produced in the ration to the influence of dairy cow digestion and metabolism and other main related indexes, so as not to add the rumen-protected lysine product as a control group. The main results of the test are shown in Table 3.

[0056] Table 3 Effects of rumen-protected lysine 2 on digestion and metabolism and other main related indicators of dairy cows

[0057]

[0058] As can be seen from Table 3, addin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com