Fast construction method of high-salt wastewater biological treatment system

A technology for biological treatment and high-salt wastewater, applied in the fields of environmental protection and sewage treatment, can solve the problems of poor stability of aerobic granular sludge, improper control of salinity elevation gradient, slow salinity elevation gradient, etc., so as to avoid serious system failure. Stable, excellent impact resistance, to achieve the effect of forming thickening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

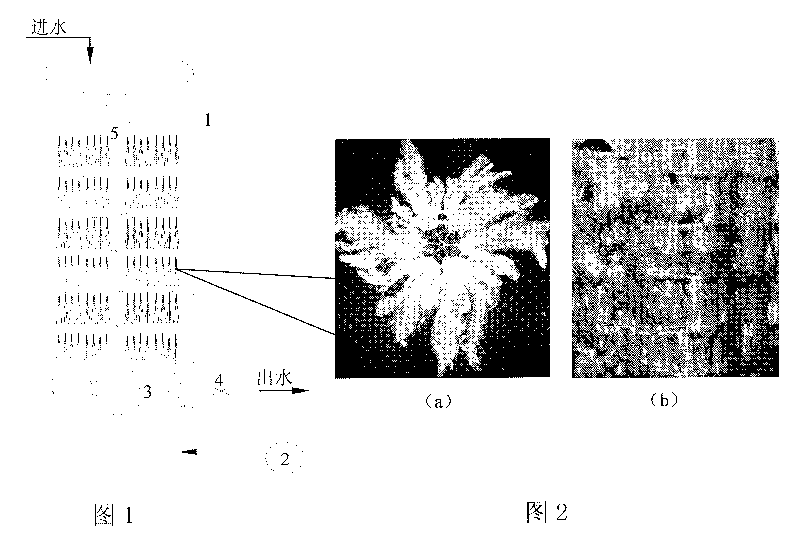

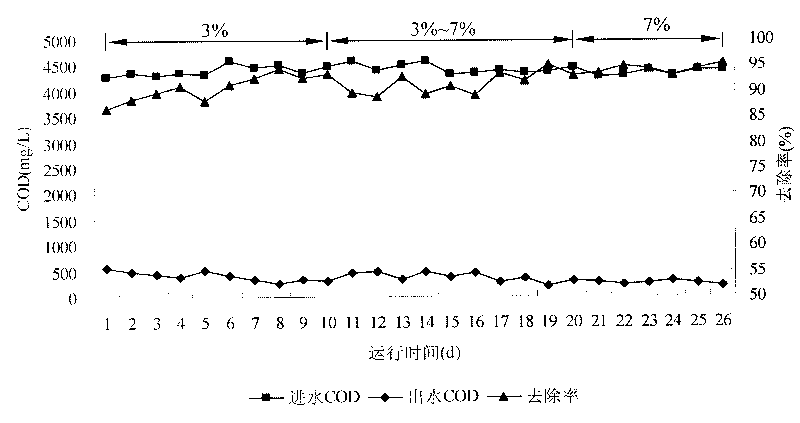

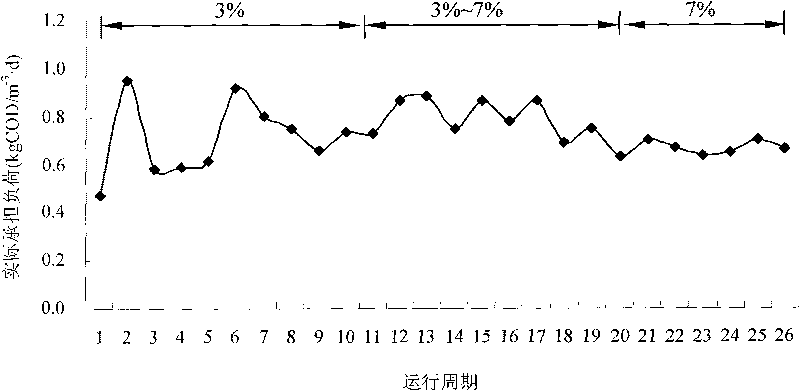

[0033] The wastewater to be treated is high-salt mustard mustard pickling wastewater, its COD value is about 5000mg / L, and the target salinity is 7% (but why use 7% in the second stage?), and its salinity is controlled at 3% and 7% salinity values, using figure 1 The shown treatment device is at 3% initial salinity, and the influent organic load is 0.5kgCOD / (m 3 · d), DO 6mg / L or so, starting under the condition of influent salinity of 3%, the first stage of operation is carried out, the water temperature is 25-30°C, the reactor operates in one cycle per day, and the operating condition is that the influent water is 0.25 h→reaction 23.5h→precipitation and drainage for 0.25h, a total of 24h, after 10 days of operation, the COD removal rate can reach 90%, and the reactor enters the second stage of operation;

[0034] In the second stage of operation, the salinity of the influent is changed to 7%. Since the salinity of the first stage of the reactor is 3%, and the drainage ratio...

Embodiment 2

[0037] The wastewater to be treated is high-salt mustard mustard pickling wastewater, its COD value is about 5000mg / L, and the target salinity is 6%. The salinity is controlled at two salinity values of 3% and 6% by adding NaCl. figure 1 The treatment device shown is at 3% initial salinity, and the influent organic load is 1.0kgCOD / (m 3 d), DO 6mg / L or so, inoculate the activated sludge of urban sewage plant to make the sludge concentration in the reactor 8g / L, the reactor film density (filler filling ratio) is 30%, and the influent salinity is 3% Start under the conditions of the first stage of operation, the water temperature is 25 ~ 30 ℃, the reactor is operated in a cycle per day, and the operating conditions are 0.15h of water intake → 23.7h of reaction → 0.15h of sedimentation and drainage, a total of 24h, after 10 days of operation , the COD removal rate can reach 88%, and the reactor enters the second stage of operation; after 10 days, the salinity in the reactor can...

Embodiment 3

[0039] Using high-salt simulated wastewater (composed of domestic sewage, glucose, ammonium chloride, potassium dihydrogen phosphate, etc.), the COD value is about 5000mg / L, the target salinity is 7%, and the salinity is controlled by adding NaCl to 3% and 7% for both salinity values, using figure 1 The shown treatment device is at 3% initial salinity, and the influent organic load is 0.5kgCOD / (m 3 · d), DO 6mg / L or so, starting under the condition of influent salinity of 3%, the first stage of operation is carried out, the water temperature is 25-30°C, the reactor operates in one cycle per day, and the operating condition is that the influent water is 0.25 h→reaction for 23.5h→precipitation and drainage for 0.25h, a total of 24h. After 10 days of operation, the COD removal rate can also reach 90%. The reactor enters the second stage of operation, and the target salinity is 7%. The salinity can reach the target salinity of 7%. At the same time, the reactor can efficiently rem...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Dissolved oxygen | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com