Method for preparing filtrate loss controller for drilling fluid by using styrene-acrylonitrile copolymer foamed plastic waste

A technology of foam plastics and drilling mud, which is applied in the direction of chemical instruments and methods, drilling compositions, etc., can solve the problems of no fluid loss control agent in drilling mud, etc., and achieve improved cuttings-carrying ability, simple reaction route, and easy preparation high efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] Adopt the following mass parts raw materials: 10 parts of styrene-acrylonitrile copolymer foam plastic waste (styrene: acrylonitrile monomer molar ratio=70: 30), 80 parts of 98% vitriol oil; Styrene-acrylonitrile copolymer foam After the plastic waste is purified and pulverized, concentrated sulfuric acid is added according to the ratio, fully stirred, and reacted at 85°C for 5 hours. The obtained product is filtered to separate the waste acid, washed with water, dried and pulverized to obtain a sulfonated hydrolyzate. The product is Dark brown powder. Add the product into the base slurry in batches under stirring conditions, the color of the base slurry becomes darker and the viscosity increases. When the product addition was mass fraction 1%, the apparent viscosity 35mpa s was recorded in the fresh water base slurry (bentonite mass fraction is 8%, the same below) at normal temperature, and the API water loss 10ml; Salt water base slurry (bentonite mass fraction is 8%...

Embodiment 2

[0017] Adopt the following mass parts raw materials: 10 parts of styrene-acrylonitrile copolymer foam plastic waste (styrene: acrylonitrile monomer molar ratio=10: 90), 100 parts of 90% vitriol oil; Styrene-acrylonitrile copolymer foam After the plastic waste is purified and pulverized, concentrated sulfuric acid is added according to the ratio, fully stirred, and reacted at 90°C for 7 hours. The obtained product is filtered to separate the waste acid, washed with water, dried and pulverized to obtain a sulfonated hydrolyzate. The product is Dark brown powder. Add the product into the base slurry in batches under stirring conditions, the color of the base slurry becomes darker and the viscosity increases. When the product addition amount is 1% by mass fraction, the apparent viscosity in the freshwater base pulp is 38mpa·s and the API water loss is 8ml; the apparent viscosity in the salt water base pulp is 34mpa·s and the API water loss is 12ml.

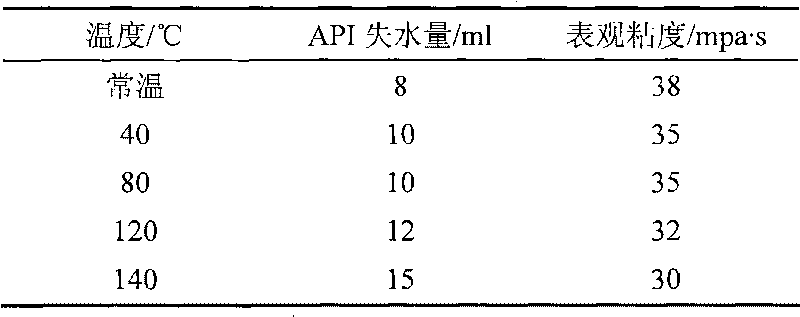

[0018] The temperature resist...

Embodiment 3

[0023] Adopt the following mass parts raw materials: 10 parts of styrene-acrylonitrile copolymer foamed plastic waste (styrene: acrylonitrile monomer molar ratio=60: 40), 20 parts of cyclohexane, 80 parts of 98% concentrated sulfuric acid; Styrene - The acrylonitrile copolymer foam plastic waste is purified and pulverized, fully swelled in cyclohexane at 60°C, added a metered amount of concentrated sulfuric acid, and reacted at 70°C for 2 hours. Separation of waste acid by filtration, washing with water, drying and crushing to obtain sulfonated hydrolyzate, the product is dark brown powder. Add the product into the base slurry in batches under stirring conditions, the color of the base slurry becomes darker and the viscosity increases. When the product addition amount is 1% by mass fraction, the apparent viscosity in the freshwater base pulp is 36mpa·s, and the API water loss is 12ml; the apparent viscosity in the salt water base pulp is 33mpa·s, and the API water loss is 14ml...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Apparent viscosity | aaaaa | aaaaa |

| Apparent viscosity | aaaaa | aaaaa |

| Apparent viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com