Seawater scouring corrosion resistant nickel-copper alloy and tubular product and preparation method thereof

A copper-nickel alloy, scouring and corrosion technology, applied in the direction of pipeline protection, mechanical equipment, pipes/pipe joints/pipe fittings, etc., can solve the problems of increasing project investment, damage and fracture caused by titanium hydrogen, and achieve expanded application and improved durability Erosion corrosion performance, effect of low corrosion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

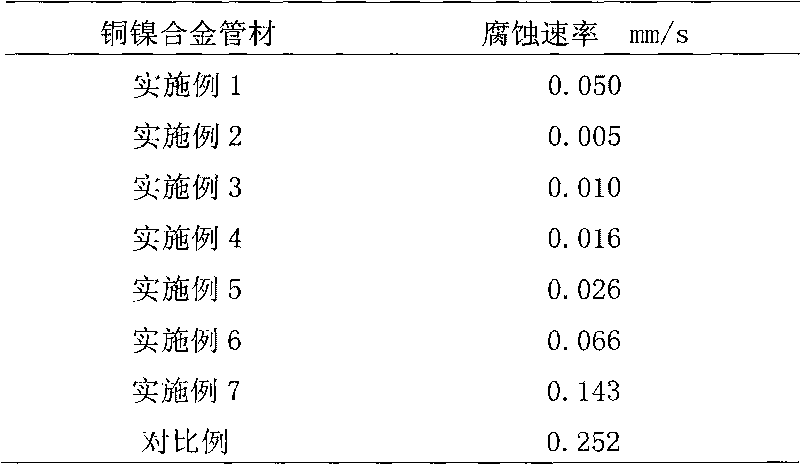

Embodiment 1

[0030] A corrosion-resistant copper-nickel alloy, the components are 7% nickel, 6% tin, 4% zinc, the impurity content is not more than 0.5%, and the balance is copper. The process of making the pipe is as follows: First, through the alloy design, the ingredients are proportioned according to the above component ratios, and after horizontal continuous casting, a pipe blank with an outer diameter of 80mm and a thickness of 20mm is prepared, and after homogenization heat treatment at 650°C for 6 hours, the outer shell is obtained after peeling. The pipe blank with a diameter of 79.5m and a thickness of 19mm is stretched, and three times of intermediate annealing is used to soften and stretch. The annealing process is an annealing temperature of 450-500°C, annealing time of 4.5 hours, and then the finished product is stretched. The outer diameter of the finished pipe is 30mm. The thickness is 2mm, and finally cut and packaged to form a finished product.

Embodiment 2

[0032] A corrosion-resistant copper-nickel alloy, the components are 10% nickel, 6% tin, 2% zinc, 2% iron, 1% cerium, the impurity content is not more than 0.5%, and the balance is copper. The process of making the pipe is as follows: First, through the alloy design, according to the proportion of the above components, the tube blank with an outer diameter of 80mm and a thickness of 20mm is prepared after horizontal continuous casting, and after homogenization heat treatment at 650°C for 6 hours, the outer diameter after peeling is 79.5mm. mm, thickness 19mm tube blank, stretching, using 3 times of intermediate annealing to soften and stretch, the annealing process is annealing temperature 450-500 ℃, annealing time 4.5 hours, and then the finished product is stretched, the outer diameter of the finished pipe is 30mm, the thickness is 2mm , and finally cut and packaged to form a finished product.

Embodiment 3

[0034] A corrosion-resistant copper-nickel alloy, the components are 5% nickel, 3% tin, 6% zinc, 2% iron, 2% lanthanum, the impurity content is not more than 0.5%, and the balance is copper. The process of making the pipe is as follows: First, through the alloy design, according to the proportion of the above components, the tube blank with an outer diameter of 80mm and a thickness of 20mm is prepared after horizontal continuous casting, and after homogenization heat treatment at 650°C for 6 hours, the outer diameter after peeling is 79.5mm. mm, thickness 19mm pipe blank, stretching, using 3 times of intermediate annealing to soften and stretch, the annealing process is annealing temperature 450-500 ℃, annealing time 4.5 hours, and then the finished product is stretched, the outer diameter of the finished pipe is 30mm, the thickness is 2mm , and finally cut and packaged to form a finished product.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer diameter | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com