Regenerated particles, particle board and preparation method thereof

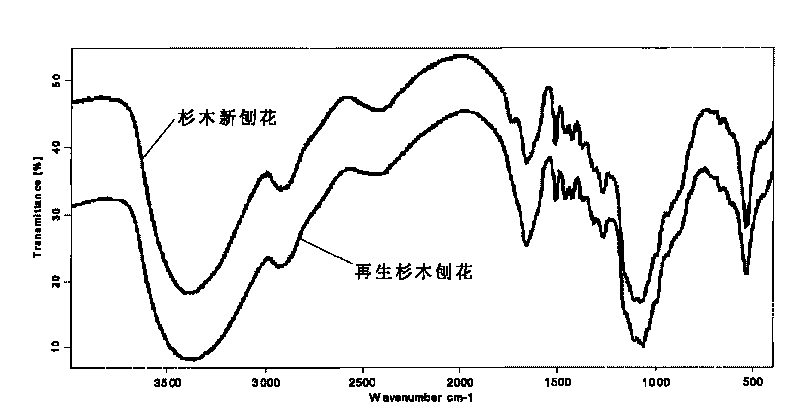

The technology of particleboard and shavings is applied in the field of particleboard raw materials and its preparation, which can solve the problems of poor shape of shavings, damage, long hydrothermal treatment time, etc., and achieve the effect of improving the plasticity of wood

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] The waste particleboard prepared from a single species of Chinese fir is made into shavings according to the following steps:

[0023] 1. Remove metal connectors, plastics, soil and other impurities in waste particleboard;

[0024] 2. Using a chipper (SiempelKamp, Germany) to break the particleboard into pieces;

[0025] 3. Screen out unqualified fragments with a size larger than 40mm×40mm, and at the same time separate debris such as sand, plastic, and small pieces of metal;

[0026] 4. Send the fragments into the blasting device, first pass 1.0MPa saturated steam for treatment, and maintain the pressure in the blasting device at 1.0MPa, and keep it for 5 minutes, when the blasting pressure in the blasting device rises to 2.0MPa, Open the discharge valve of the blasting device, so that the fragments are instantly blasted and sprayed into the receiving container to obtain recycled shavings.

[0027] 5. Dry the recycled shavings to the required moisture content of 3-5%...

Embodiment 2

[0037] In the process of making waste particleboard into regenerated shavings, in addition to using mixed tree species to prepare waste particleboard, and introducing 1.2MPa saturated steam to maintain the steam treatment pressure in the blasting device at 1.2MPa for 3 minutes and the blasting pressure at 2.5 Except MPa, all the other are the same with embodiment 1.

[0038] In the process of preparing particleboard by using recycled shavings, the weight ratio of new shavings and recycled shavings is 1:1.5, and the new shavings are mixed shavings, the rest is the same as that of Example 1.

[0039] The performance test results of the prepared particleboard are shown in Table 1.

Embodiment 3

[0041] In the process of making waste particleboard into regenerated shavings, except for the waste particleboard prepared by mixed tree species, 1.5MPa saturated steam was introduced to maintain the steam treatment pressure in the blasting device at 1.5MPa for 3 minutes and the blasting pressure at 2.0 MPa, all the other are the same with embodiment 1.

[0042] In the process of preparing particleboard with recycled shavings, except that the weight ratio of new shavings and recycled shavings is 1:0.67, and the new shavings are mixed shavings, the rest is the same as in Example 1.

[0043] The performance test results of the prepared particleboard are shown in Table 1.

[0044] Table 1 product performance test results

[0045]

Performance Testing

density

g / cm 3

moisture content

%

static bending strength

MPa

MPa

internal binding strength

MPa

Water absorption thickness

Exp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pressure | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com