Method for preparing tri-dimension-limited crystal-facet-dependent silicon nanostructures

A silicon nano and three-dimensional technology, applied in the fields of nanostructure manufacturing, nanotechnology, nanotechnology, etc., can solve problems such as unfavorable large-scale integration of devices, increased device power consumption, and increased device resistance, etc. device resistance, the effect of overcoming inconsistencies

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

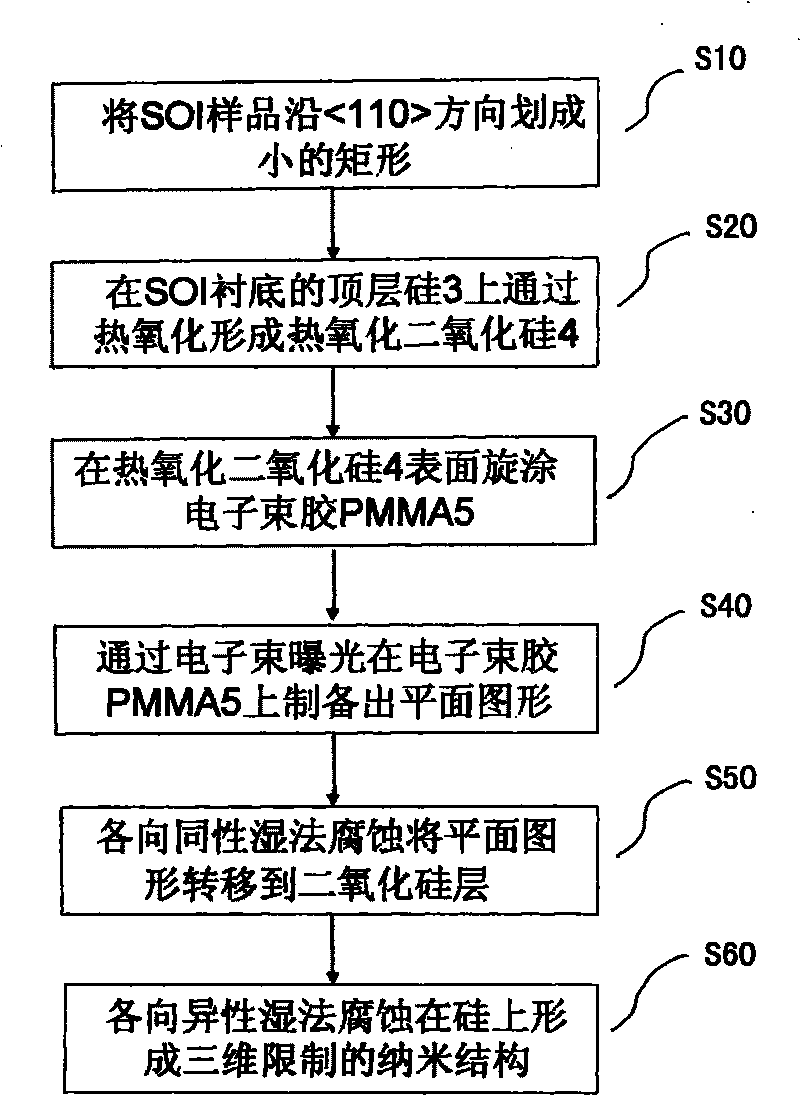

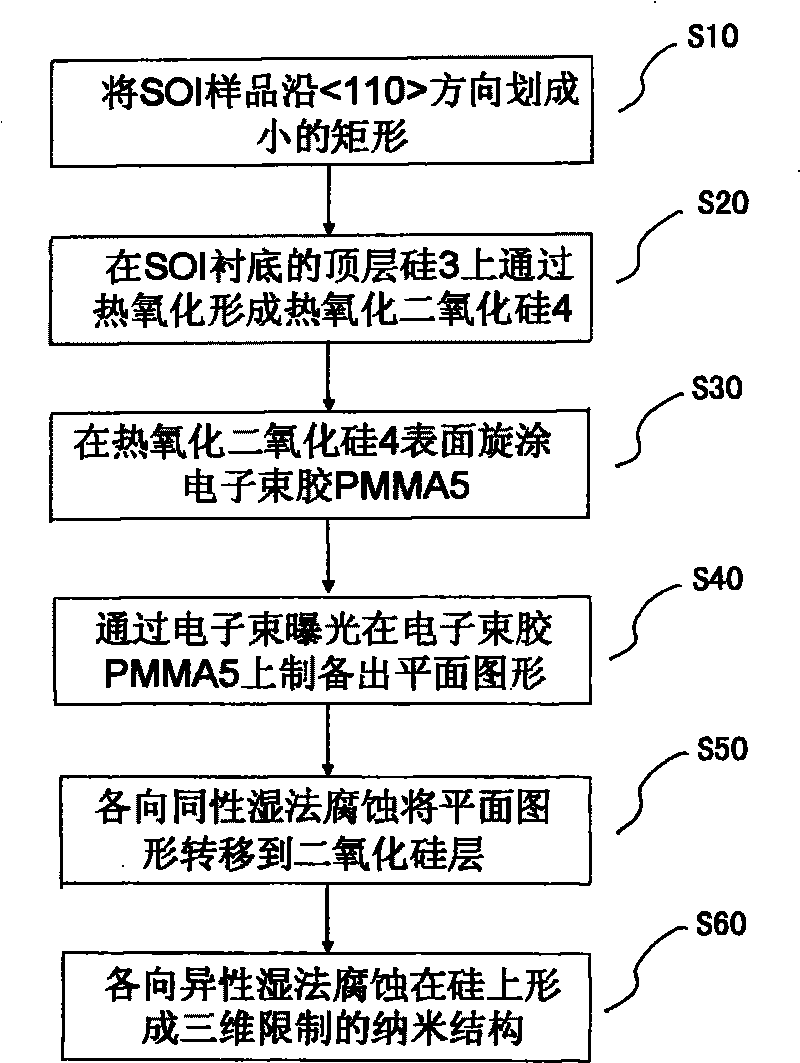

[0030] see figure 2 , figure 2 Shown is a flow chart of making a three-dimensional confined silicon nanostructure dependent on a crystal plane. A method for preparing a three-dimensional confined silicon nanostructure dependent on a crystal plane in the present invention comprises the following steps:

[0031] Step S10: using silicon-on-insulator as the substrate, and the crystal plane orientation of the top layer silicon of the silicon-on-insulator material is (100);

[0032] Step S20: Carry out scribing on the substrate along the crystal direction, as a reference direction during exposure;

[0033] Step S30: performing thermal oxidation on the substrate to form a silicon dioxide mask layer;

[0034] Step S40: Using electron beam exposure to generate a planar pattern, the electron beam exposure uses positive electron beam glue PMMA as a resist, and the planar pattern generated by electron beam exposure is based on the nanowire pattern There are openings at both ends of ...

Embodiment

[0039] based on figure 2 The flow chart for preparing a three-dimensional confinement silicon nanostructure dependent on crystal planes is shown, and the method for preparing a three-dimensional confinement silicon nanostructure dependent on crystal planes of the present invention will be further described in detail below in conjunction with specific examples.

Embodiment approach

[0040]A kind of process implementation method utilizing electron beam exposure provided by the present invention, specifically comprises the following steps:

[0041] (1) Determine the reference direction during electron beam exposure: Since the marking edge of the (100) oriented SOI substrate is along the crystal direction, it can be used as a reference edge for scribing. In the subsequent electron beam exposure process , which is further used as a reference direction during electron beam exposure;

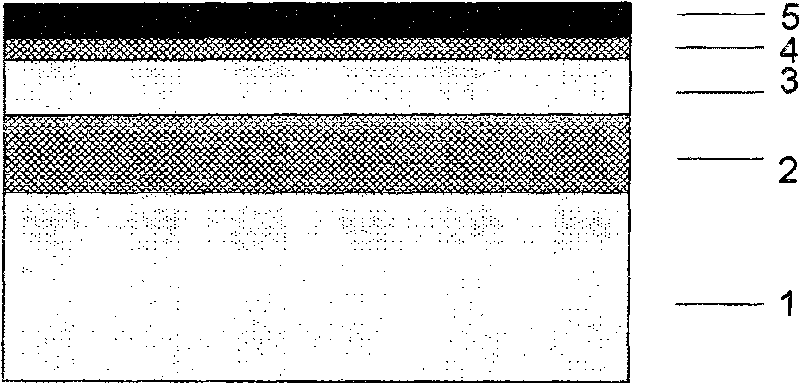

[0042] (2) thermal oxidation: yes figure 1 The top layer of silicon 3 on the SOI substrate shown in is thermally oxidized to form a 20nm thick silicon dioxide mask layer 4 on the surface of the top layer of silicon 3, and the thermally oxidized silicon dioxide of this layer is used as Masking layers for anisotropic wet etching.

[0043] (3) spin-coated electron beam glue: in figure 1 Spin-coat a layer of electron beam glue 5PMMA EL4 on the surface of the thermally oxidized si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com